Feather protein fiber and method for preparing same

A feather protein and fiber technology is applied in the field of wood feather protein fiber and its preparation, which can solve the problems such as insufficient utilization of vane resources, and achieve the effect of excellent anti-wrinkle performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

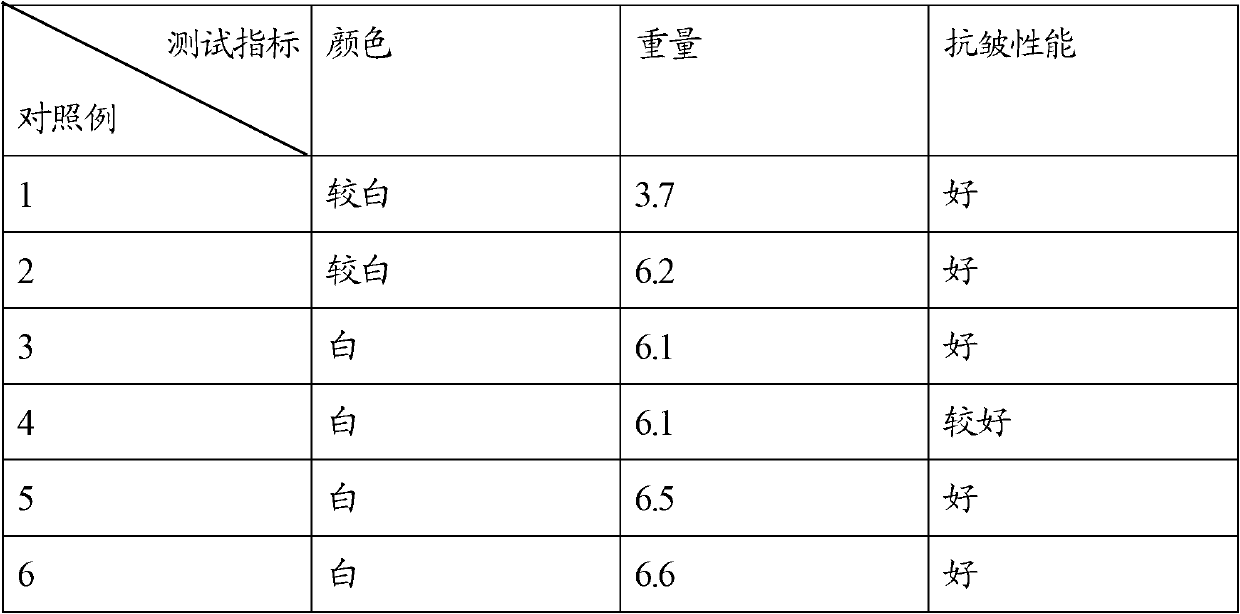

Examples

Embodiment 1

[0068] A, the preparation of feather protein spinning solution: 1kg feather is placed in 0.6kg mass concentration and is 35% alkaline aqueous solution after pressure is 200kPa, and temperature is 150 ℃ after being mechanically crushed and ground into feather powder. The temperature of the alkaline aqueous solution is 60°C, which contains 0.2kg sodium silicate, potassium silicate and 0.01kg calcium silicate, and the mass ratio of feathers to sodium silicate and potassium silicate in the alkaline solution is 1:0.2; The alkaline aqueous solution was filtered to remove insoluble impurities, and 0.3 mL of hydrogen peroxide was added to the obtained filtrate according to a volume ratio of 0.05% to obtain a feather protein spinning solution.

[0069] B, feather protein spinning solution and wood cellulose viscose fiber spinning solution are blended and spun: the feather protein spinning solution and wood cellulose viscose fiber spinning solution are degassed respectively and are 40% b...

Embodiment 2

[0072]A, the preparation of feather protein spinning solution: 1kg feather is placed in the alkaline aqueous solution of 25% after being placed in 0.44kg mass concentration after the pressure is 220kPa, and the temperature is 160 ℃ through mechanical crushing and grinding. Said alkaline aqueous solution temperature is 45 ℃, and it contains 0.1kg sodium silicate, potassium silicate and 0.01kg calcium hydroxide, and the mass ratio of sodium silicate and potassium silicate in feather and alkaline solution is 1:0.1; The alkaline aqueous solution is filtered to remove insoluble impurities, and 0.26 mL of hydrogen peroxide is added to the obtained filtrate according to its volume ratio of 0.06% to obtain a feather protein spinning solution.

[0073] B, feather protein spinning solution and wood cellulose viscose fiber spinning solution are blended and spun: the feather protein spinning solution and wood cellulose viscose fiber spinning solution are degassed respectively and are 15% b...

Embodiment 3

[0076] A, the preparation of feather protein spinning solution: 1kg feather is placed in the alkaline aqueous solution of 30% after being placed in 0.55kg mass concentration after the pressure is 230kPa, and the temperature is 170 ℃ through mechanical crushing and grinding. Said alkaline aqueous solution temperature is 50 ℃, and it contains 0.15kg sodium silicate, potassium silicate and 0.015kg calcium silicate, and the mass ratio of sodium silicate and potassium silicate in feather and alkaline aqueous solution is 1:0.15; The alkaline aqueous solution is filtered to remove insoluble impurities, and 0.44 mL of hydrogen peroxide is added to the obtained filtrate according to its volume ratio of 0.08% to obtain a feather protein spinning solution.

[0077] B, feather protein spinning solution and wood cellulose viscose fiber spinning solution are blended and spun: the feather protein spinning solution and wood cellulose viscose fiber spinning solution are degassed respectively an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com