Method of preparing feather protein powder from keratinase

A technology of feather protein powder and keratinase, which is applied in application, animal feed, animal husbandry, etc., can solve the problems of hidden safety hazards, increased production costs of producers, and complicated procedures, so as to broaden the applicable field of technology and improve comprehensive economic benefits , the effect of a wide range of pH action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] one. Materials and methods

[0024] Material

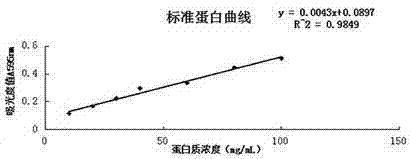

[0025] Chicken and duck feathers (obtained from poultry slaughterhouse), keratinase: 100000U / g (Jinan Nuoneng Bioengineering Co., Ltd.), 1mol / L NaOH solution, 1mol / L HCL solution, distilled water, Coomassie brilliant blue reagent (weighed Dissolve 100mg of Coomassie Brilliant Blue G-250 in 50ml of 95% ethanol, add 100mL of 85% phosphoric acid, and dilute to 1000mL with distilled water), protein standard solution (crystalline bovine serum albumin, the protein nitrogen content was determined by micro-Kjeldahl method in advance, according to Its purity is formulated as a protein standard solution of 100μg / mL.), pepsin (the actual titer of protease is 1:3000).

[0026] 2. Main equipment

[0027] main instrument

[0028] 18 250mL Erlenmeyer flasks, pipette (10mL), test tube and test tube rack, volumetric flask (50mL), mortar, 100 mesh standard sieve, dropper, funnel, filter paper, measuring cylinder, pipette (100-1000μl; 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

| decomposition efficiency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com