Preparation method of activated carbon

A technology of activated carbon and carbonization, which is applied in the direction of chemical instruments and methods, inorganic chemistry, non-metallic elements, etc., can solve the problems of underutilization, low utilization rate and low value of use, and reduce material costs, avoid pollution, and carbonization temperature low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

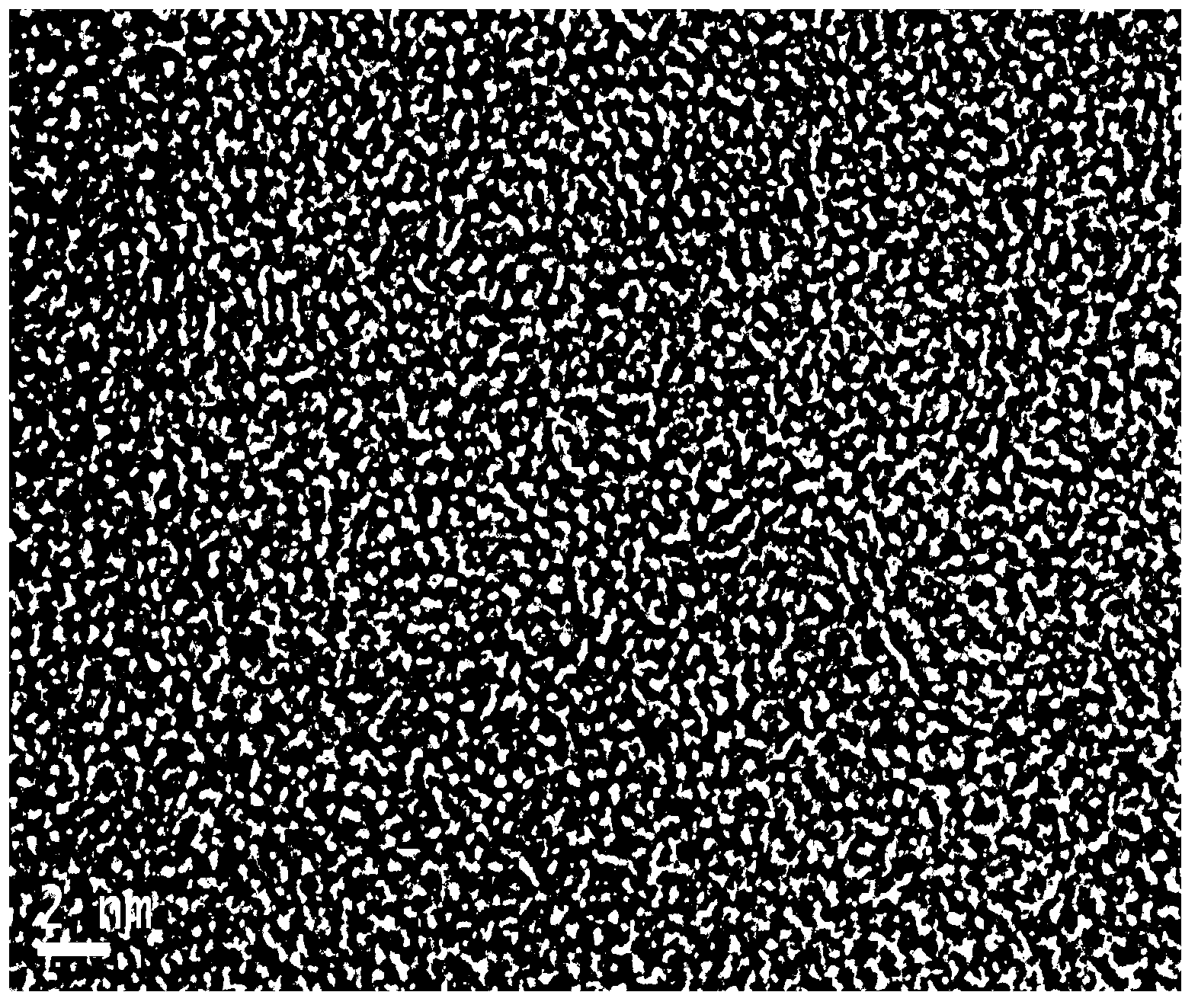

Image

Examples

Embodiment 1

[0019] Wash the feathers with clean water and dry them at a temperature of 40°C;

[0020] Put the treated feathers into a crucible, put them into a tubular resistance furnace, and raise the temperature to 350°C at a rate of 1°C / min under the protection of an inert gas, keep it warm for 60 minutes, and then lower it to room temperature;

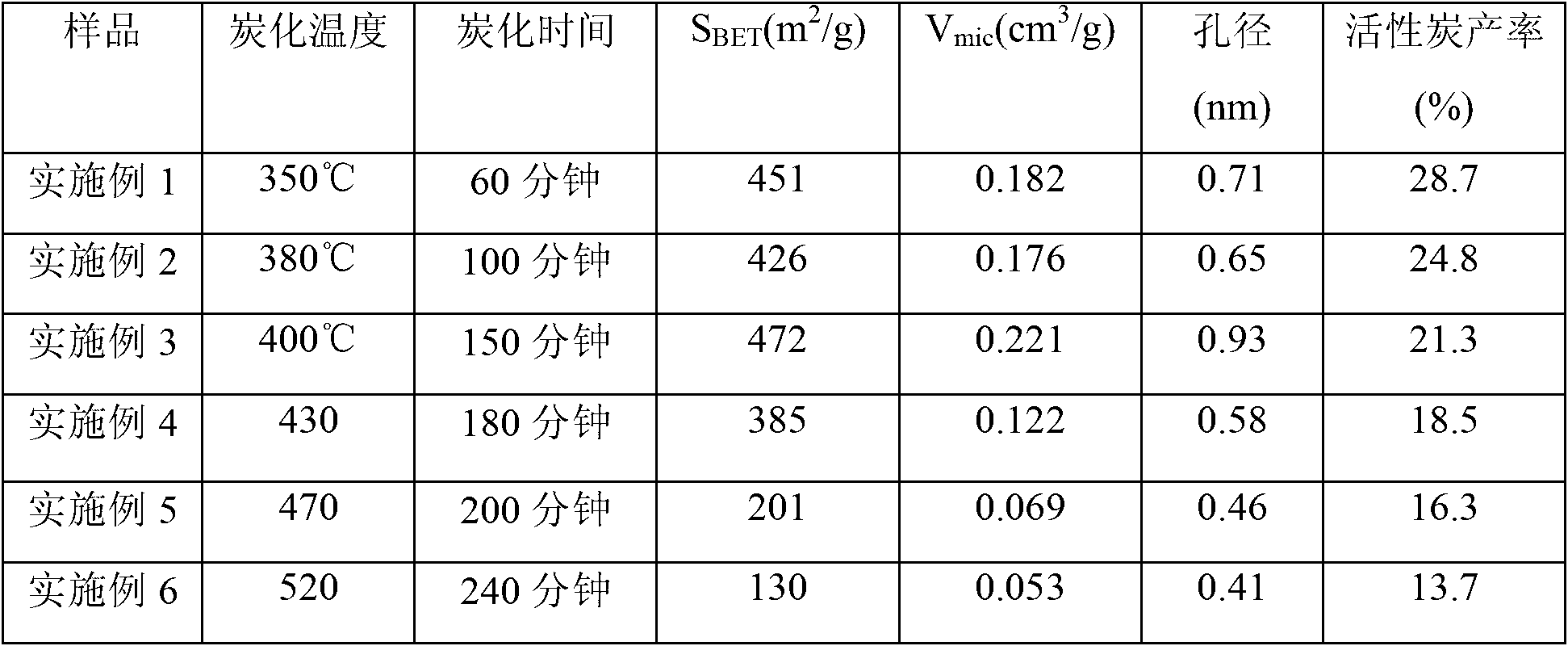

[0021] Put the carbonized feathers into a grinding tank, grind them for 30 minutes quickly, and then sieve (400 mesh) to obtain microporous activated carbon. Calculate the activated carbon yield (activated carbon yield = mass of carbonized product / mass of substance before carbonization), and measure its specific surface area, micropore volume and pore diameter with a nitrogen adsorption / desorption instrument. The results are shown in Table 1.

Embodiment 2

[0023] Wash the feathers with clean water and dry them at a temperature of 60°C;

[0024] Put the treated feathers into a crucible, put them into a tubular resistance furnace, and raise the temperature to 380°C at a rate of 5°C / min under the protection of an inert gas, keep it warm for 100 minutes, and then cool down to room temperature;

[0025] Put the carbonized feathers into a grinding tank, grind them for 30 minutes quickly, and then sieve (400 mesh) to obtain microporous activated carbon. The activated carbon yield was calculated (activated carbon yield = mass of carbonized product / mass of substance before carbonization), and its specific surface area, micropore volume and pore diameter were measured with a nitrogen adsorption instrument / desorption instrument. The results are shown in Table 1.

Embodiment 3

[0027] Wash the feathers with clean water and dry them at a temperature of 80°C;

[0028] Put the treated feathers into a crucible, put them into a tube furnace, and raise the temperature to 400°C at a heating rate of 10°C / min under the protection of an inert gas, keep it warm for 150 minutes, and then cool down to room temperature;

[0029] Put the carbonized feathers into a grinding tank, grind them for 30 minutes quickly, and then sieve (400 mesh) to obtain microporous activated carbon. The activated carbon yield was calculated (activated carbon yield = mass of carbonized product / mass of substance before carbonization), and its specific surface area, micropore volume and pore diameter were measured with a nitrogen adsorption / desorption instrument. The results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com