Multi-stage blocking pressure-bearing plugging agent

A technology of plugging agent and plugging agent, which is applied in the field of multi-stage plugging and pressure-bearing plugging agent, which can solve the problems of inability to optimize and determine the formula of plugging agent, increase the uncertainty of successful construction, and reduce the success rate of plugging , to achieve the effects of wide applicability of plugging, shortening drilling time, improving plugging ability and pressure stabilizing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

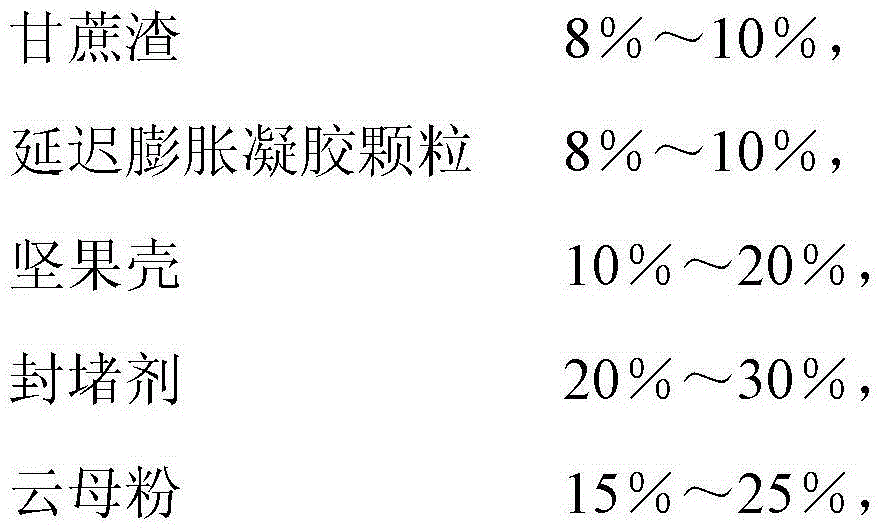

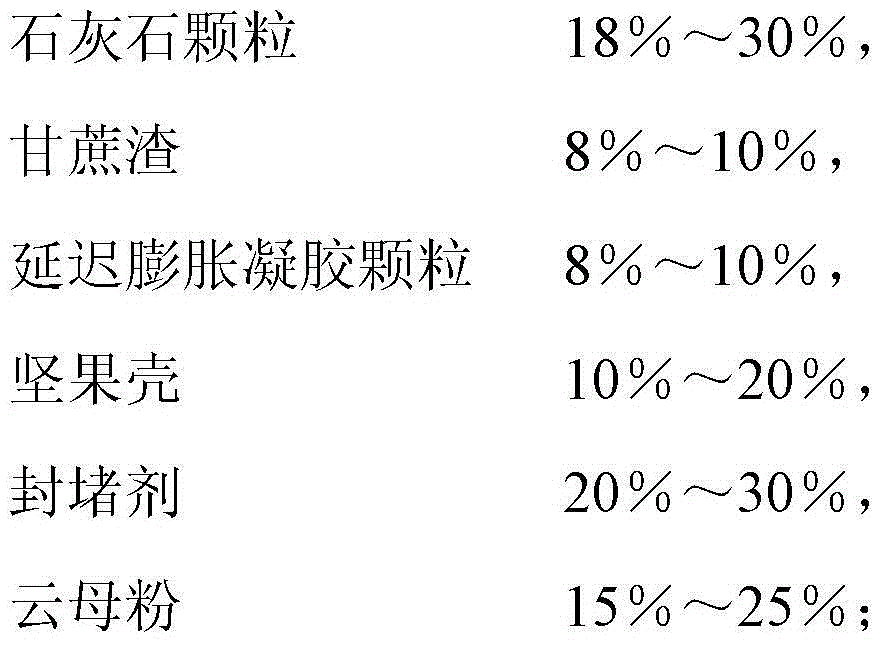

[0022] Plugging agent 1: limestone particles 8-15 mesh 5%, 20-40 mesh 8%, 60-70 mesh 5%, bagasse 8%, polyacrylamide gel particles 8%, nut shell 5-8 mesh 6% , 10% of 10-20 mesh, 30% of plugging agent, 10% of mica powder of 5-7 mesh, 10% of 8-12 mesh, wherein the weight ratio of plugging agent components is: sulfonated asphalt 15%, lignin fiber 25%, superfine calcium carbonate 40%, lignite resin 20%.

[0023] Plugging slurry formula: 2000mL 8wt% sodium soil mud + 15wt% plugging agent 1;

[0024] The pressure bearing capacity of the plugging agent in this embodiment is: 7MPa (maximum pressure of the instrument) for a 2mm×1mm wedge-shaped seam mold.

Embodiment 2

[0026] Plugging agent 2: limestone particles 8-15 mesh 8%, 20-40 mesh 9%, 60-70 mesh 8%, bagasse 10%, polyacrylamide gel particles 10%, nut shell 5-7 mesh 10% , 9-12 mesh 5%, plugging agent 25%, mica powder 5-8 mesh 10%, 10-20 mesh 5%, wherein the weight ratio of plugging agent components is: sulfonated asphalt 25%, lignin fiber 20%, superfine calcium carbonate 40%, lignite resin 15%.

[0027] Plugging slurry formula: 2000mL 8wt% sodium soil mud + 15wt% plugging agent 2; the pressure bearing capacity of the plugging agent in this example: 7MPa for a 3mm×2mm wedge-shaped seam mold.

Embodiment 3

[0029] Plugging agent 3: limestone particles 8-15 mesh 10%, 20-40 mesh 10%, 60-70 mesh 10%, bagasse 10%, polyacrylamide gel particles 10%, nut shell 5-8 mesh 5% , 10-20 mesh 5%, plugging agent 20%, mica powder 5-7 mesh 15%, 8-12 mesh 5%, wherein the weight ratio of plugging agent components is: sulfonated asphalt 25%, lignin fiber 35%, superfine calcium carbonate 20%, lignite resin 20%.

[0030] Plugging slurry formula: 2000mL 8wt% sodium soil mud + 20wt% plugging agent 3;

[0031] The pressure bearing capacity of the plugging agent in this embodiment: 7MPa for a 4mm×3mm wedge-shaped seam mold.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com