New process for producing alkaline hydrogen peroxide mechanical pulp by double scrwe extruding method

A technology of twin-screw extrusion and hydrogen peroxide, which is applied in the direction of cellulose raw material pulping, pulp bleaching, pulp beating/refining methods, etc. , Unstable slurry concentration and other problems, to improve the final pulp quality, improve the extrusion tearing effect, and ensure the effect of refining quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

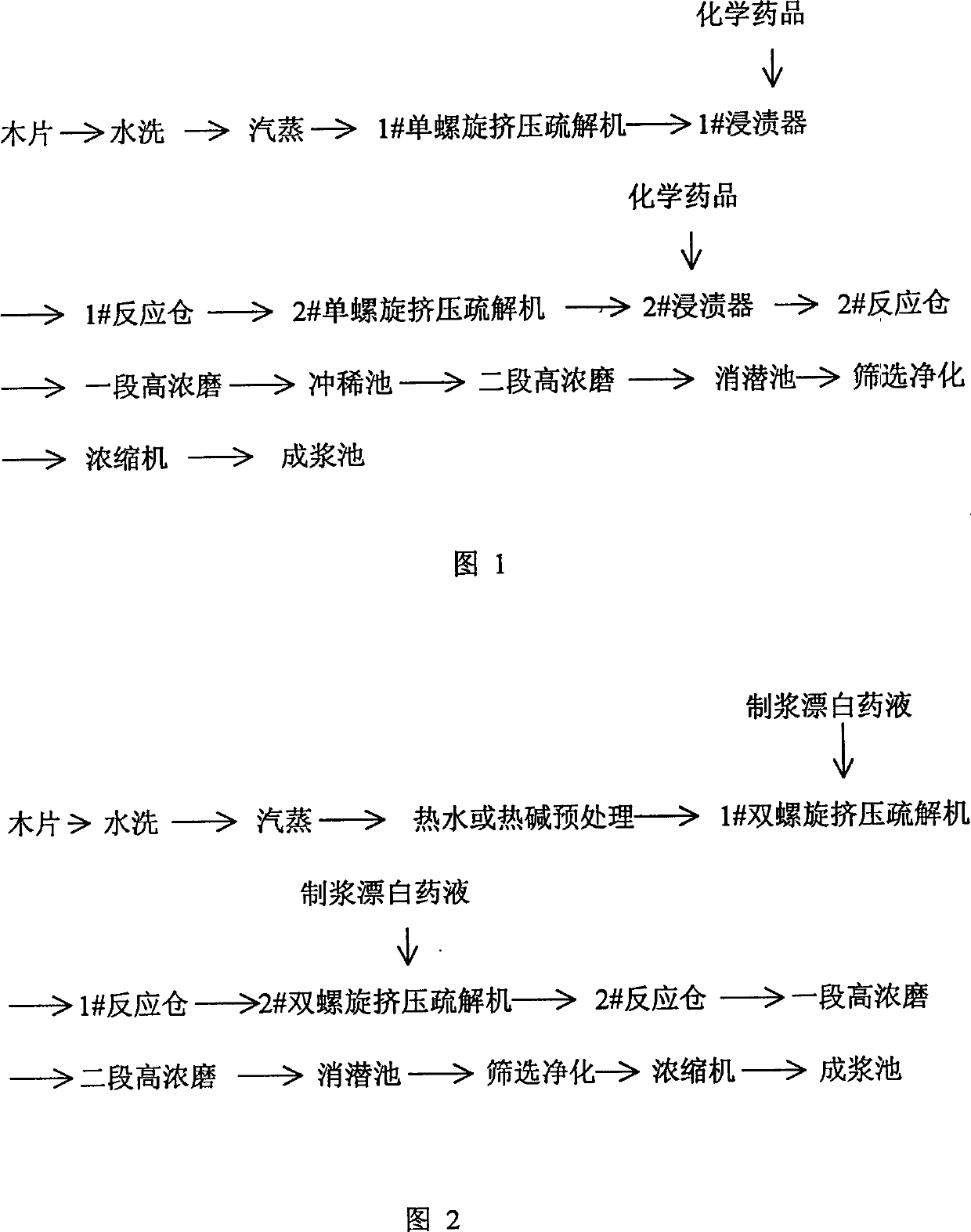

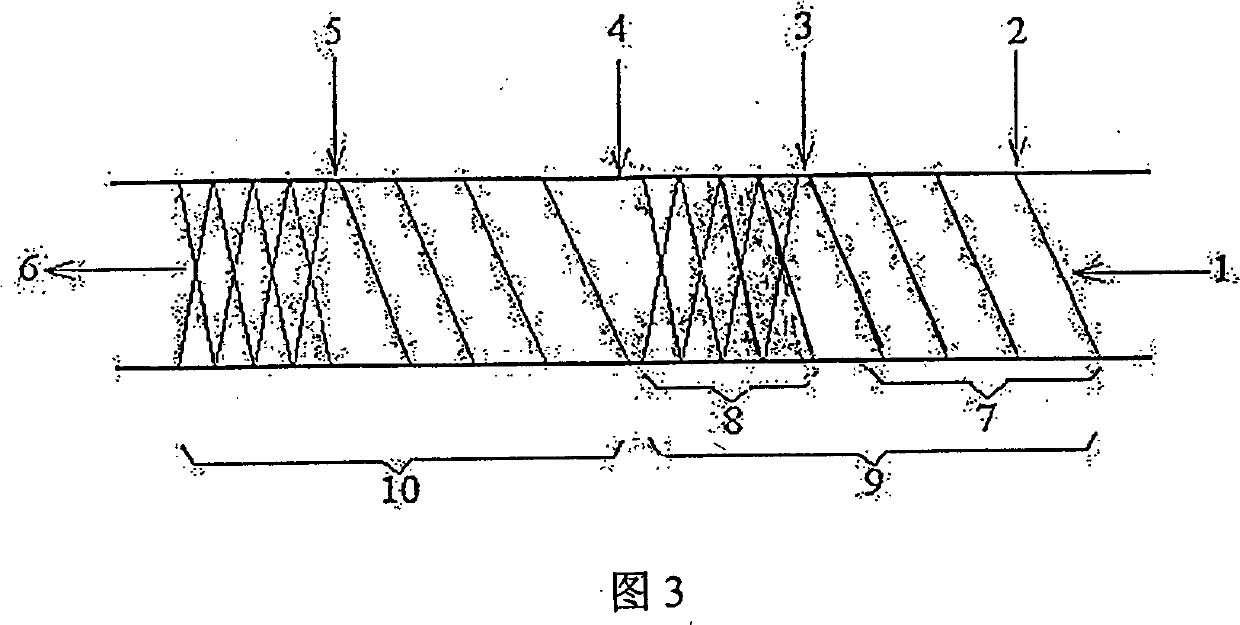

[0046] Select poplar wood chip for use as pulping raw material, referring to Fig. 2, technological process of the present invention, by wood chip washing, steaming, hot water or hot alkali pretreatment, 1# twin-screw extruding deflaking machine, 1# reaction chamber, 2 #Double-screw extruding deflaking machine, 2# reaction chamber, one-stage high-consistency mill, two-stage high-consistency mill, submerged pool, screening and purification, thickener and slurry pool and other processes, the process will be the existing technical process in Figure 1 1# single-screw extruding deflagging machine and 1# impregnator and 2# single-screw extruding deflagging machine and 2# impregnating device are replaced by 1# twin-screw extruding deflagging machine and 2# twin-screw extruding deflagging machine of the present invention , so that the extrusion deflaking and impregnation processes in the process are combined into one, and it is completed by the twin-screw extruding deflagging machine. N...

PUM

| Property | Measurement | Unit |

|---|---|---|

| whiteness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com