Wood plastic composite material

A technology of wood-plastic composite materials and waste plastics, applied in the field of wood-plastic composite materials, can solve the problems of limited mechanical properties, limited strength of finished products, unfavorable processing and production, etc., and achieve good product stability, increase mechanical strength, and improve dispersion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

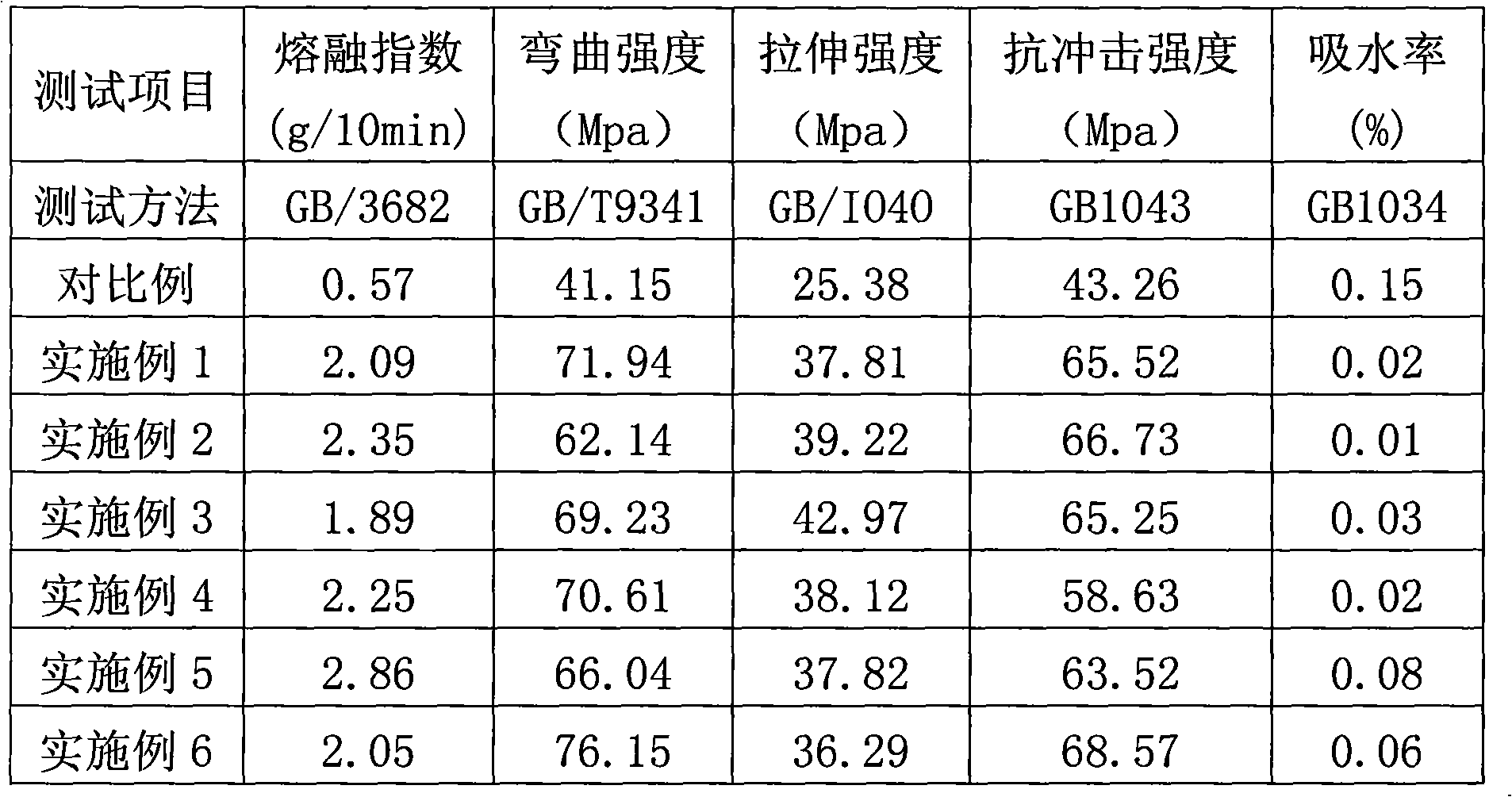

Examples

Embodiment 1

[0021] A wood-plastic composite material, comprising the following components:

[0022] Wood powder 100 mesh 100

[0023] Waste plastic (HDPE) 50

[0024] Waste rubber (POE) 10

[0025] High melting point thermoplastic resin (HDPE): 40

[0026] Surfactant 1.5

[0027] Lubricant (amide wax) 2

[0029] Lubricant (calcium stearate) 0.3

[0030] Crosslinking agent (dicumyl peroxide) 0.5

[0031] Antioxidant: 0.2

[0032] Processing aids: 0.1.

Embodiment 2

[0034] A wood-plastic composite material, comprising the following components:

[0035] Wood powder 325 mesh 100

[0036] Waste plastic (HDPE) 50

[0037] Waste rubber (POE) 10

[0038] High melting index thermoplastic resin (HDPE) 40

[0039] Surfactant 1.5

[0040] Lubricant (amide wax) 2

[0041] Lubricant (MP Wax) 2

[0042] Lubricant (calcium stearate) 0.3

[0043] Crosslinking agent (dicumyl peroxide) 0.5

[0044] Antioxidant 0.2

[0045] Processing aids: 0.1.

Embodiment 3

[0047] A wood-plastic composite material, comprising the following components:

[0048] Wood powder 100 mesh 100

[0049] Waste plastic (PP) 50

[0050] Waste rubber (TPU) 30

[0051] High melting point thermoplastic resin (HDPE): 20

[0052] Surfactant 1.5

[0053] Lubricant (amide wax) 2

[0054] Lubricant (MP Wax) 2

[0055] Lubricant (oleic acid amide) 0.3

[0056] Crosslinking agent (dicumyl peroxide) 0.5

[0057] Antioxidant: 0.2

[0058] Processing aids: 0.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com