Long-acting mould-proof wood plastic composite material and preparation method thereof

A wood-plastic composite material and anti-mold technology, which is applied to wood processing appliances, flat products, and other household appliances, etc., can solve the problems of poor anti-mold performance and achieve high water absorption resistance, good long-term anti-mold performance, and hardness Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

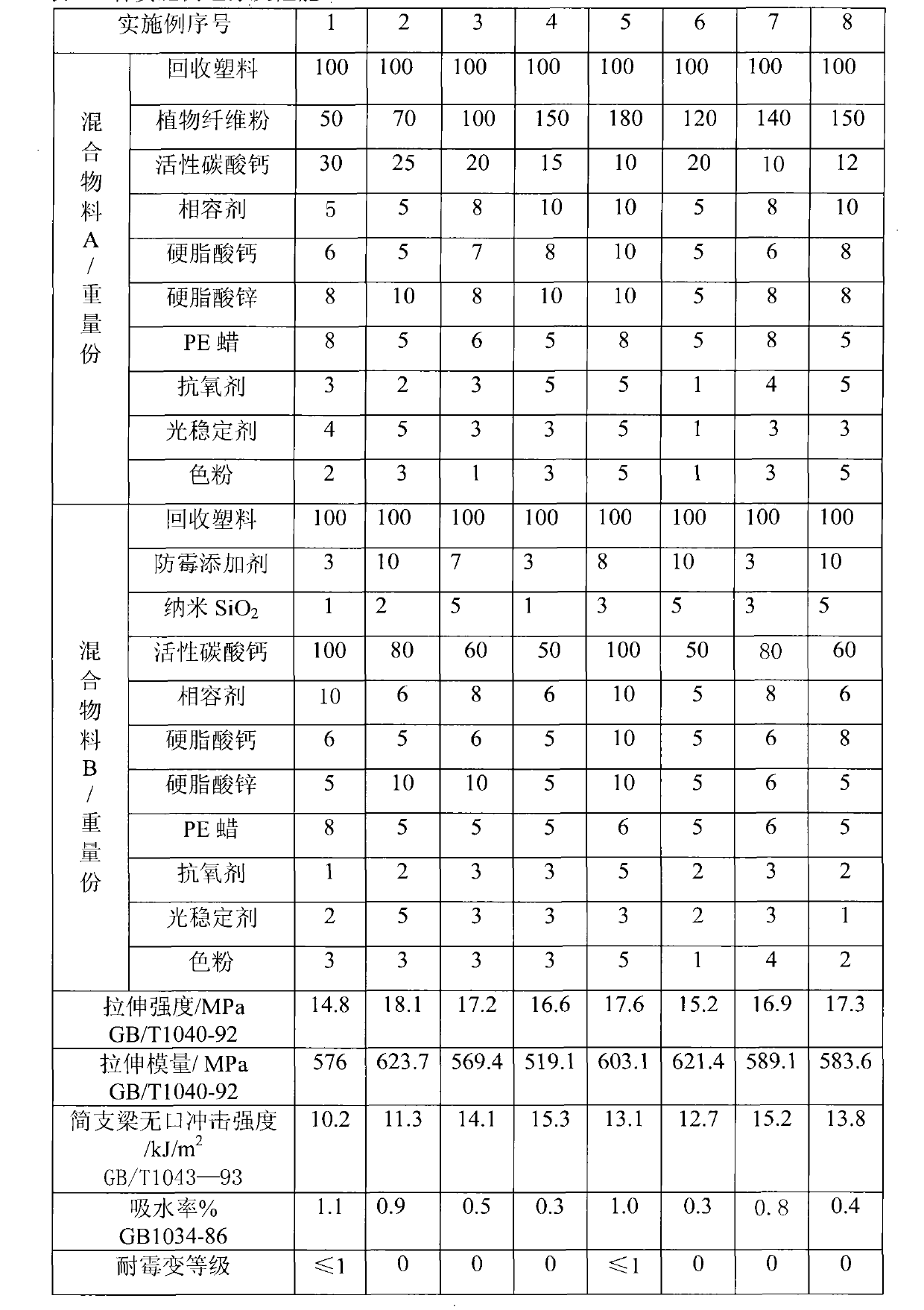

Examples

Embodiment 1

[0049] Weigh and dry 100 parts of recycled PE plastic powder with a particle size of 50 mesh, 50 parts of wood powder with a particle size of 300 mesh, 30 parts of activated calcium carbonate, 5 parts of compatibilizer PE-gMAH, calcium stearate 6 parts, 8 parts of zinc stearate, 8 parts of PE wax, 10763 parts of antioxidant, 2924 parts of light stabilizer, 2 parts of toner, put the above raw materials into a high-speed mixer, at 90 ° C, 90 rpm Mix at a high speed for 18 minutes at a speed of 10 minutes to obtain a mixed material A.

[0050] Take 100 parts of 60-mesh recycled PE plastic powder, anti-mildew additive nano-TiO 2 3 parts, 100 parts of active calcium carbonate, nano-SiO 21 part, 10 parts of compatibilizer PE-gMAH, 6 parts of calcium stearate, 5 parts of zinc stearate, 8 parts of PE wax, 1 part of antioxidant 1076, 2922 parts of light stabilizer, 3 parts of toner, the above The raw materials were put into a high-speed mixer, and mixed at a high speed of 90° C. for...

Embodiment 2

[0058] Weigh 100 parts of recycled PP plastic powder with a particle size of 60 mesh, 70 parts of bamboo powder with a particle size of 250 mesh, 25 parts of active calcium carbonate, 5 parts of compatibilizer PP-g-MAH, and stearic acid according to the weight ratio. 5 parts of calcium, 10 parts of zinc stearate, 5 parts of PE wax, 2 parts of antioxidant 300, 5 parts of light stabilizer 765, 3 parts of toner, put the above raw materials into a high-speed mixer, at 95 ° C, Mixed at a high speed for 16 minutes at a speed of 100 rpm to obtain a mixed material A.

[0059] Take 100 parts of recycled PP plastic powder of 60 meshes, anti-mildew additive nano-TiO 2 10 parts, 80 parts of active calcium carbonate, nano-SiO 2 2 parts, 6 parts of compatibilizer PP-g-MAH, 5 parts of calcium stearate, 10 parts of zinc stearate, 5 parts of PE wax, 3002 parts of antioxidant, 5 parts of light stabilizer 765, 3 parts of toner , put the above-mentioned raw materials into a high-speed mixer, a...

Embodiment 3

[0066] Weigh and dry 100 parts of recycled PVC plastic powder with a particle size of 80 mesh, 100 parts of rice bran with a particle size of 200 mesh, 20 parts of activated calcium carbonate, 8 parts of compatibilizer CPE-g-MAH, stearin 7 parts of calcium carbonate, 8 parts of zinc stearate, 6 parts of PE wax, 3 parts of antioxidant 1010, 3 parts of light stabilizer 3346, and 1 part of toner. , 90 revolutions per minute, high-speed mixing for 15 minutes to obtain the mixed material A.

[0067] Take 100 parts of recycled PVC plastic powder of 70 meshes, anti-mildew additive nano-TiO 2 7 parts, 60 parts of active calcium carbonate, nano-SiO 2 5 parts, 8 parts of compatibilizer CPE-g-MAH, 6 parts of calcium stearate, 10 parts of zinc stearate, 5 parts of PE wax, 10103 parts of antioxidant, 3 parts of light stabilizer 3346, 3 parts of toner , put the above-mentioned raw materials into a high-speed mixer, and mix them at a high speed for 15 minutes at 100° C. at a speed of 90 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Inner layer thickness | aaaaa | aaaaa |

| Outer layer thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com