Anti-mildew halogen-free flame-retardant smoke-suppression wood-plastic composite material and preparation method thereof

A wood-plastic composite material and anti-mildew technology, which is applied in the field of wood-plastic composite materials and its preparation, can solve the problems of material physical and mechanical properties decline, large amount of flame retardant APP added, and increase in production costs, so as to reduce the amount of APP , good flame retardant performance, the effect of reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

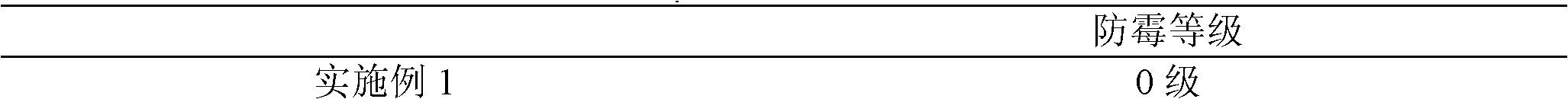

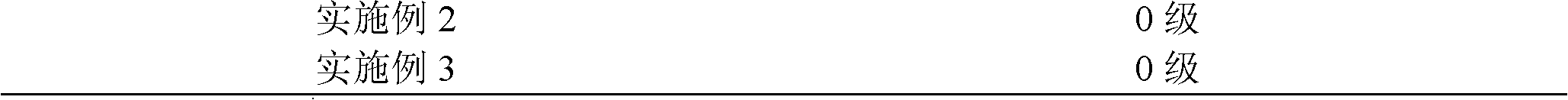

Embodiment 1

[0039] Raw material components are calculated in parts by mass:

[0040] Recycled high-density polyethylene: 40 parts by mass

[0041] Waste polyvinyl chloride: 15 parts by mass

[0042] Chinese fir powder (80 mesh): 40 parts by mass

[0043] Camphor wood powder (60 mesh): 7.5 parts by mass

[0044] EVA-g-PVC: 4.5 parts by mass

[0045] MAH-g-PE: 4 parts by mass

[0046] CPE: 5 parts by mass

[0047] Liquid paraffin: 1 part by mass

[0048] Ammonium polyphosphate (polymerization degree 2000): 20 parts by mass

[0049] Melamine: 5 parts by mass

[0050] Zinc borate: 2 parts by mass

[0051] Calcium zinc heat stabilizer: 2.5 parts by mass

[0052] Antioxidant 1010: 0.1 parts by mass

[0053] The preparation method is as follows:

[0054] (1) First vacuum-dry the Chinese fir powder and the camphor powder at 120°C for 6 hours, so that the moisture content of the Chinese fir powder and the camphor powder is lower than 2%;

[0055] (2) Add HDPE resin, PVC resin, main com...

Embodiment 2

[0059] According to raw material components by mass parts:

[0060] Recycled high-density polyethylene: 50 parts by mass

[0061] Waste polyvinyl chloride: 20 parts by mass

[0062] Bamboo powder (40 orders): 45 parts by mass

[0063] Camphor wood powder (80 mesh): 8 parts by mass

[0064] EVA-g-PVC: 4 parts by mass

[0065] MAH-g-POE: 4.5 parts by mass

[0066] EPDM: 4.5 parts by mass

[0067] Calcium stearate: 1.5 parts by mass

[0068] Calcium zinc heat stabilizer: 3 parts by mass

[0069] Ammonium polyphosphate (polymerization degree 4000): 20 parts by mass

[0070] Pentaerythritol: 5 parts by mass

[0071] Montmorillonite (nano-level): 5 parts by mass

[0072] Antioxidant 168: 0.1 parts by mass

[0073] According to the preparation process described in Example 1, the mildew-proof, halogen-free, flame-retardant, smoke-suppressing wood-plastic composite product was obtained through extrusion molding.

[0074] The anti-mildew, halogen-free, flame-retardant and smo...

Embodiment 3

[0076] According to raw material components by mass parts:

[0077] Recycled high-density polyethylene: 45 parts by mass

[0078] Waste polyvinyl chloride: 15 parts by mass

[0079] Chinese fir powder (60 mesh): 45 parts by mass

[0080] Camphor wood powder (100 mesh): 10 parts by mass

[0081] MAH-g-PE: 4.5 parts by mass

[0082] EVA-g-PVC: 3.5 parts by mass

[0083] POE: 6.5 parts by mass

[0084] Stearic acid: 1.5 parts by mass

[0085] Phenolic resin: 5 parts by mass

[0086] Magnesium hydroxide (superfine): 10 parts by mass

[0087] Ammonium polyphosphate (polymerization degree 2000): 20 parts by mass

[0088] Calcium zinc heat stabilizer: 2.5 parts by mass

[0089] Antioxidant 1010: 0.1 parts by mass

[0090] According to the preparation process described in Example 1, the mildew-proof, halogen-free, flame-retardant, smoke-suppressing wood-plastic composite product was obtained through extrusion molding.

[0091] The anti-mildew, halogen-free, flame-retardant ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com