Flexible flat cable and method of manufacturing the same

一种柔性扁平电缆、构造成的技术,应用在扁平/带状电缆、电缆/导体制造、绝缘电缆等方向,能够解决不可能利用、不能获得均一结构等问题,达到廉价柔韧性、低成本、满足柔韧性和绝缘可靠性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0053] Hereinafter, embodiments of the flexible flat cable of the present invention will be specifically described.

[0054] The ingredients shown in Table 1 were used as raw materials of the resin composition, and the materials shown in Table 1 were kneaded using a twin-screw kneading extruder or a kneader to obtain the mixing amounts shown in Tables 2 to 4 ( parts by weight), thereby obtaining 12 kinds of resin compositions.

[0055] [Table 1]

[0056]

[0057] [Table 2]

[0058]

[0059] [table 3]

[0060]

[0061] [Table 4]

[0062]

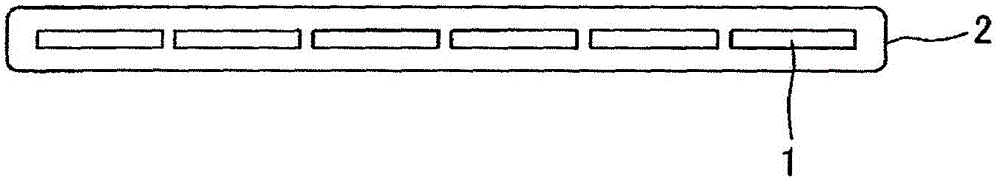

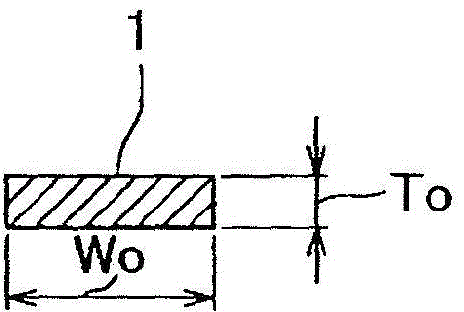

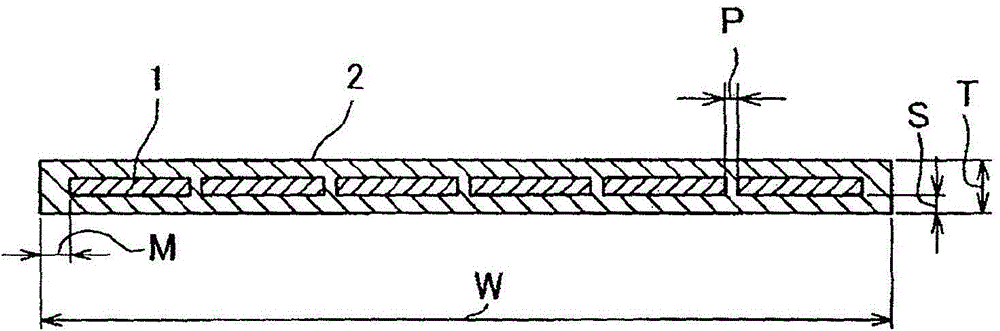

[0063] Next, flexible flat cables were produced by extrusion using 12 kinds of resin compositions ( figure 1 model of the section shown). Specifically, six right-angle conductors made of electrical copper having a width Wo of 2.0 mm and a thickness To of 0.15 mm, six right-angle conductors having a width Wo of 2.0 mm and a thickness To of 0.10 mm, or having a width of 2.0 mm Six right-angle conductors of Wo and thickness To ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tension | aaaaa | aaaaa |

| tension | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com