Polyolefin and preparation method thereof

A polyolefin and olefin comonomer technology, applied in the field of polyolefin, can solve the problems of unstable physical properties, rough appearance, etc., and achieve the effect of excellent formability and high die expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

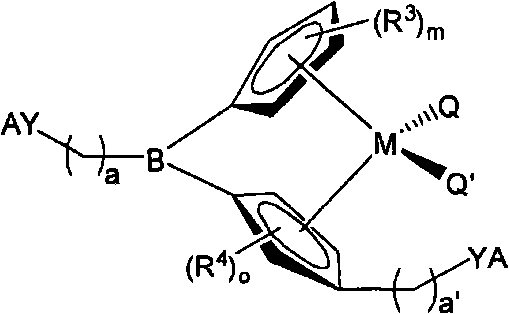

[0068] In the method for preparing polyolefins according to the present invention, silica, silica-alumina, and silica-magnesia dried at high temperature can be used as a carrier that can be used to manufacture a supported composite metallocene catalyst , and they can often include oxides such as Na 2 O, K 2 CO 3 , BaSO 4 , Mg(NO 3 ) 2 And carbonate, sulfate, nitrate components.

[0069] It is preferable that the number of hydroxyl groups (-OH) on the surface of the support is as small as possible, but it is practically difficult to remove all the hydroxyl groups (-OH). Therefore, the amount of hydroxyl groups (—OH) is preferably in the range of 0.1-10 mmol / g, more preferably 0.1-1 mmol / g, and most preferably 0.1-0.5 mmol / g. The amount of surface hydroxyl groups (—OH) can be controlled by using the production conditions or methods of the carrier, or the drying conditions or methods (temperature, time, pressure, etc.). In addition, in order to reduce a side reaction cause...

preparation Embodiment 1

[0120] Preparation of the first metallocene catalyst-synthesis [ t Bu-O-(CH 2 ) 6 -C 5 h 4 ] 2 ZrCl 2

[0121] The preparation of tert-butyl-O-(CH 2 ) 6 -Cl, and react NaCp against it to obtain tert-butyl-O-(CH 2 ) 6 -C 5 h 5 (Yield 60%, b.p. 80°C / 0.1 mmHg). In addition, tert-butyl-O-(CH 2 ) 6 -C 5 h 5 It was dissolved in THF at -78°C, n-butyllithium (n-BuLi) was slowly added thereto, the temperature was raised to room temperature, and the reaction was performed for 8 hours. Allow the solution to react for an additional 6 h at room temperature while slowly adding the synthesized lithium salt solution to the ZrCl at -78 °C 4 (THF) 2(1.70g, 4.50mmol) / THF (30ml) suspension. All volatile materials were vacuum dried and hexane solvent was added to obtain oily liquid material which was then filtered. After the filtrate was vacuum-dried, hexane was added thereto to cause precipitation at low temperature (-20°C). The obtained precipitate was filtered at low tempe...

preparation Embodiment 2

[0124] Preparation of the first metallocene catalyst-synthesis [ t Bu-O-(CH 2 ) 6 -C 5 h 4 ] 2 HfCl 2

[0125] The preparation of tert-butyl-O-(CH 2 ) 6 -Cl, and react NaCp against it to obtain tert-butyl-O-(CH 2 ) 6 -C 5 h 5 (Yield 60%, b.p. 80°C / 0.1mmHg). In addition, tert-butyl-O-(CH 2 ) 6 -C 5 h 5 It was dissolved in THF at -78°C, n-butyllithium (n-BuLi) was slowly added thereto, the temperature was raised to room temperature, and the reaction was performed for 8 hours. Allow the solution to react for an additional 6 h at room temperature while slowly adding the synthesized lithium salt solution to HfCl at -78 °C 4 (1.44g, 4.50mmol) / THF (30ml) suspension. All volatile materials were vacuum dried and hexane solvent was added to obtain oily liquid material which was then filtered. After the filtrate was vacuum-dried, hexane was added thereto to cause precipitation at low temperature (-20°C). The obtained precipitate was filtered at low temperature to obt...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com