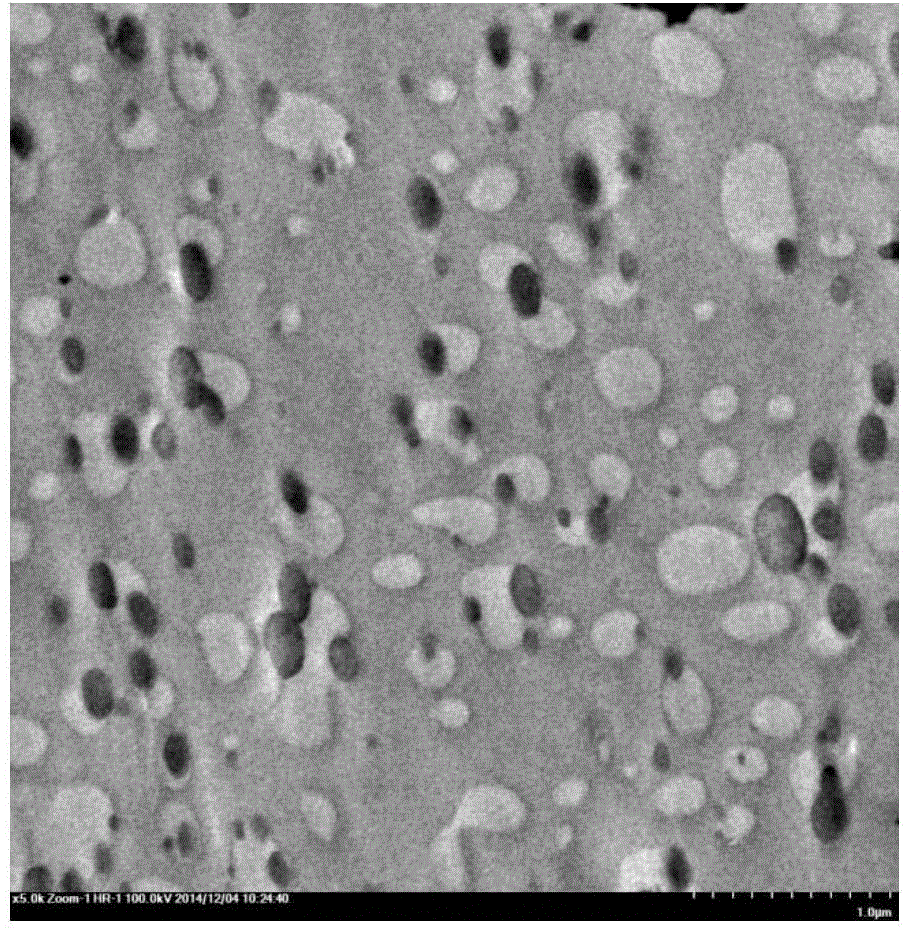

Polycarbonate resin composition with nano-scale dispersed phase state and preparation method therefor

A polycarbonate resin and polycarbonate technology, which is applied in the field of polymer material processing, can solve the problems that PC/ABS resin composition is difficult to achieve balance of impact, rigidity, thermal and mechanical properties, and poor heat resistance of alloys. , to achieve the effect of improving the mold expansion phenomenon, improving the interface properties, and reducing the size of the domains

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

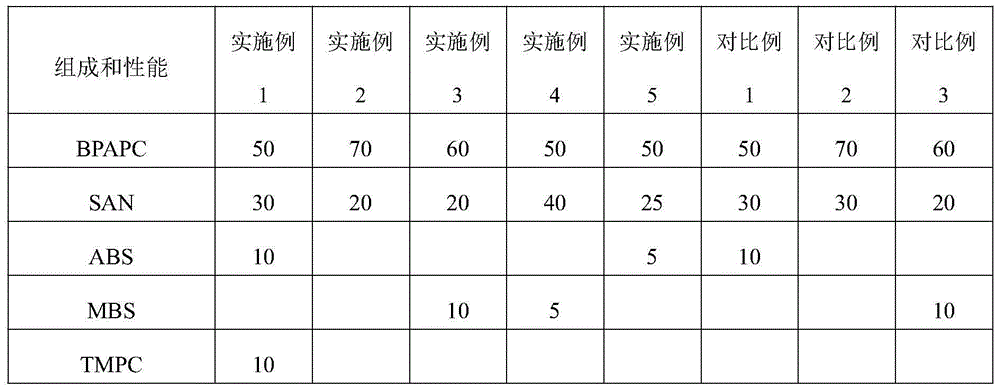

Embodiment 1~5 and comparative example 1~3

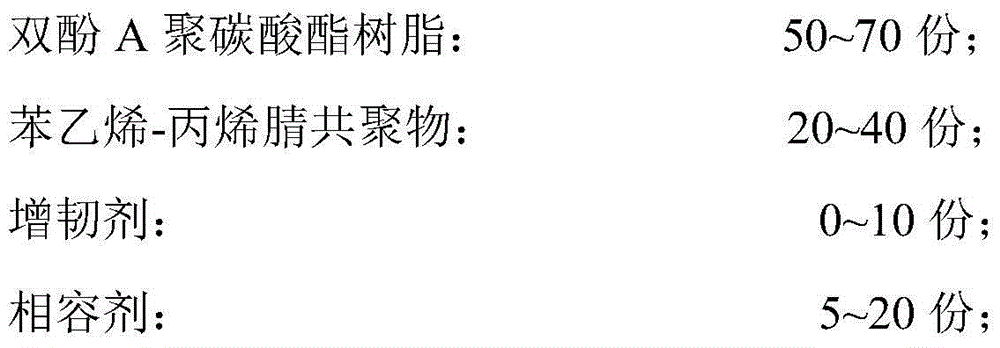

[0026] The raw materials used are:

[0027] BPAPC, the weight average molecular weight is 35,000;

[0028] SAN, the weight-average molecular weight is 120,000, and the weight percentage of acrylonitrile is 24%;

[0029] ABS, the average particle size of the particles is 300nm, the weight percentage of butadiene is 50%, and the weight percentage of acrylonitrile is 12%;

[0030] MBS, the average particle size of the particles is 250nm, and the weight percentage of butadiene is 60%;

[0031] TMPC, weight average molecular weight 45,000;

[0032] TMPC-PMMA1, weight average molecular weight 108,000, TMPCwt% = 74%;

[0033] TMPC-PMMA2, weight average molecular weight 108,000, TMPCwt%=41%;

[0034] TMPC-DMPC1, weight average molecular weight 28,000, TMPCwt% = 83%.

[0035] TMPC-DMPC2, weight average molecular weight 28,000, TMPCwt%=50%.

[0036] Take each component according to the parts by weight shown in Table 1, then adopt the following method to prepare the polycarbonate r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com