Method for improving stability of polypropylene melt

A polypropylene and stability technology, which is applied in the field of improving the stability of polypropylene melt, can solve the problems of reduced dimensional stability and increased viscoelasticity of the melt, and achieve the effects of stable melt size, increased processing speed, and reduced cost

Inactive Publication Date: 2013-01-16

文彦飞

View PDF26 Cites 6 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In fact, simply increasing the melt strength often leads to an increase in viscoelasticity, which in turn leads to a decrease in the dimensional stability of the melt

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

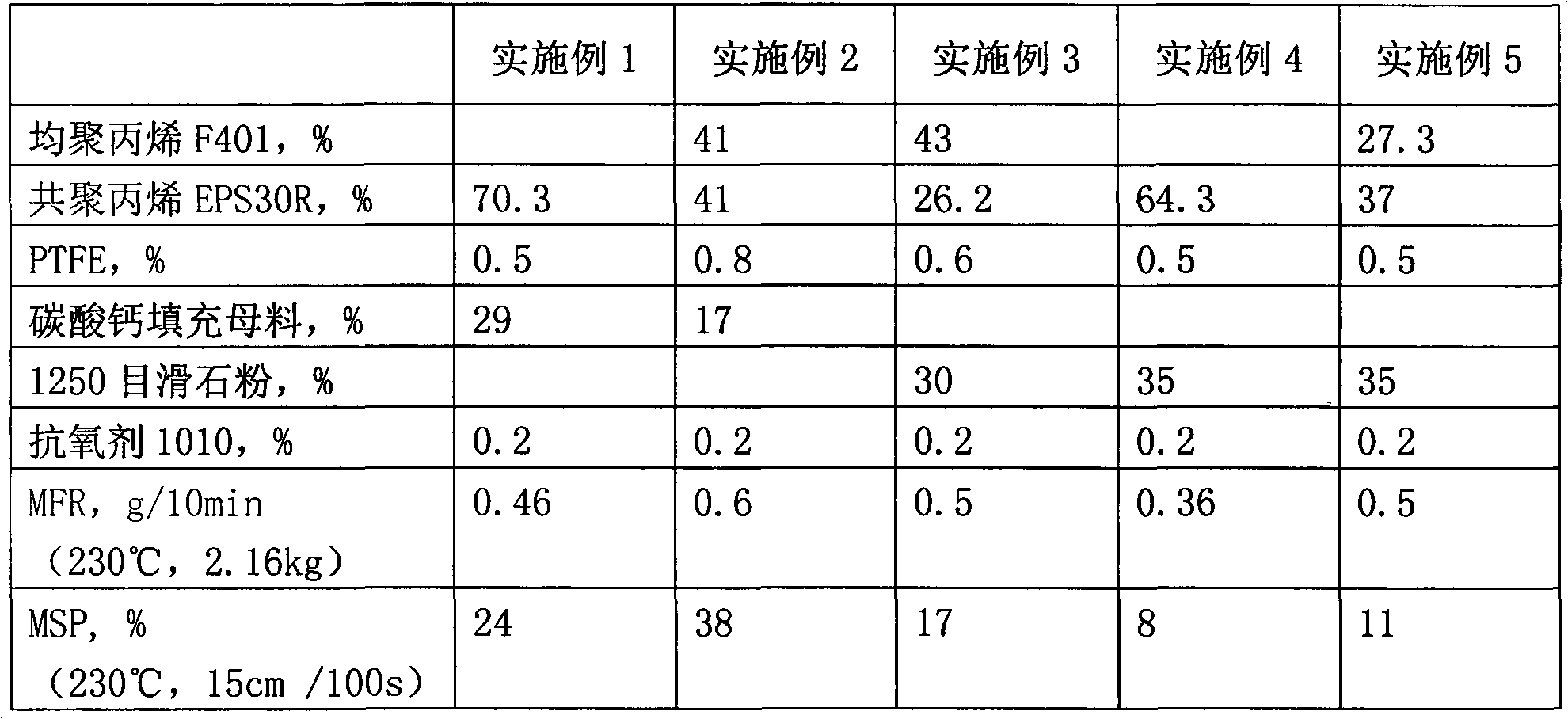

[0041] The formulations of all the examples were mixed by an internal mixer and tested with a melt flow rate instrument under the same process parameters.

[0042]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a principle and a method for improving the stability of a polypropylene melt. The method and the principle are characterized in that: by adding a tetrafluoroethylene polymer with a polypropylene melt strength enhancing function and a flaky component with a melt die swell control function, the melt die swell phenomenon is significantly reduced, and the obtained polypropylene modified material is suitable for thermal forming of various large parts, thus meeting the requirements for extrusion of hollow plates and large-diameter pipes. During extrusion blow molding of large hollow products, the melt dimensional stability can also be ensured. The method and the principle also have the advantages of enhancing the processing speed and reducing the cost.

Description

technical field [0001] The invention relates to a principle and method for improving the stability of polypropylene melt, which is characterized in that by simultaneously adding tetrafluoroethylene polymer with the function of enhancing the strength of polypropylene melt and a sheet-shaped polymer with the function of controlling the die expansion of the melt components, which significantly reduces the melt die expansion phenomenon, and meets the requirements of melt strength and dimensional stability for thermoforming and extrusion blowing processes. Background technique [0002] Polypropylene is cheap and has good overall performance. It is widely used in the fields of thermoforming, hollow extrusion, and hollow blow molding. However, ordinary polypropylene has low melt strength and high viscoelasticity, resulting in variable dimensions during thermoforming and extrusion. The controllability is very poor, which reduces the qualified rate of products and limits the increase...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08L23/12C08L23/14C08L27/18C08K7/00C08K3/04C08K3/34C08K3/26

Inventor 文彦飞

Owner 文彦飞

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com