Manufacturing method of medical absorpable suture

A technology of suture and copolymer, which is applied in the field of preparation of medical absorbable suture, can solve the problems of poor flexibility of collagen thread, poor knot stability, fast loss of tensile strength, etc., and achieve high retained fracture strength, The effect of wound healing with small scars and light tissue reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0014] A preparation method of medical absorbable suture:

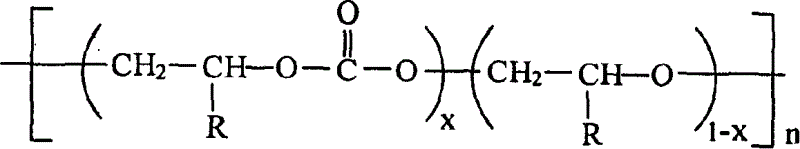

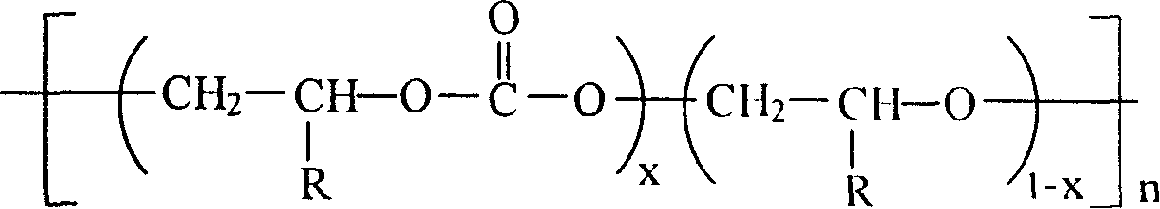

[0015] (1) It takes carbon dioxide copolymer as raw material, and the structural formula of carbon dioxide copolymer is:

[0016]

[0017] x=0.5-1.0

[0018] R = H, CH 3 ,

[0019] n is an integer between 200 and 5,000, corresponding to a number average molecular weight between 20,000 and 500,000.

[0020] The above-mentioned carbon dioxide copolymer of the present invention can be carbon dioxide-ethylene oxide copolymer, or carbon dioxide-propylene oxide copolymer, or carbon dioxide-oxidized cyclohexane copolymer, or carbon dioxide-oxidized styrene copolymer, or carbon dioxide-epoxy Propane-cyclohexane terpolymer, or one or both of carbon dioxide-propylene oxide-ethylene oxide terpolymer.

[0021] The preparation method of the above-mentioned carbon dioxide copolymer of the present invention is the same as the method disclosed in 98125655.4 and 00136189.9, and will not be described in detail here.

[0022] ...

Embodiment 1

[0030] The carbon dioxide copolymer (carbon dioxide-propylene oxide unit content 58%, number average molecular weight 21000, molecular weight distribution index 4.2) was melted at 120°C, and 4wt% maleic anhydride was added to the copolymer weight to blend and granulate. The granulated carbon dioxide copolymer is spun by a spinning machine or melted at 155 ° C. After removing air bubbles, it passes through a spinneret with a hole diameter of 4 mm, and forms fibers of 2 mm after preliminary drafting. Secondary stretching was carried out in a water bath at ℃ to prepare a 2-0 suture with a strength of 26.50N.

Embodiment 2

[0032] The carbon dioxide copolymer (carbon dioxide-propylene oxide unit content 100%, number average molecular weight 198000, molecular weight distribution index 5.3) was melted at 150°C, and blended and granulated after adding 1.2wt% maleic anhydride of the copolymer weight . The granulated carbon dioxide copolymer is spun by a spinning machine or melted at 160 ° C. After removing air bubbles, it passes through a spinneret with a hole diameter of 6 mm, and is initially drawn to form a primary fiber of 4 mm. Secondary stretching was carried out in a water bath at 25°C to prepare a 6-0 suture with a strength of 2.50N.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com