Preparation method of polyglycolic acid methyl ester absorbable surgical suture

A technology of polymethyl glycolate and methyl glycolate is applied in the directions of surgery, single-component copolyester rayon, medical science, etc. Small healing scars, good knotting performance, and mild tissue reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

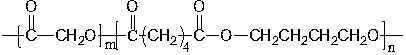

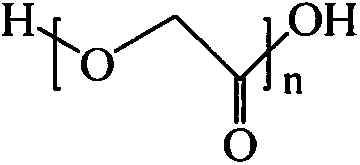

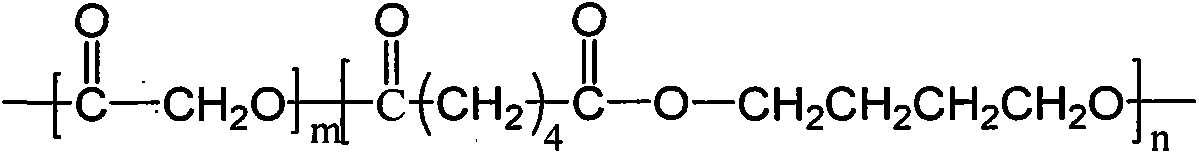

[0029] At first, methyl glycolate copolymer adopts following method to prepare:

[0030] 100 mol of methyl glycolate, 0.2 mol of adipic acid, and 0.2 mol of butanediol were added to the polymerization reactor, and precondensation was carried out at a stirring speed of 150 rpm and in the presence of a polymerization catalyst. Wherein, the polymerization catalyst is a mixture prepared by titanium isopropoxide and taurine in a mass ratio of 2:1, and the amount of the polymerization catalyst is 0.1% of the total mass of methyl glycolate. The precondensation temperature is 130-190° C., the reaction time is 8 hours, and the precondensation product is obtained. Under the stirring condition of 150 rev / min, the polycondensation product is subjected to polycondensation reaction to prepare methyl glycolate copolyester, the polycondensation temperature is 180-235° C., the reaction time is 12 hours, and the vacuum degree is 0.1-100 mmHg. The methyl glycolate copolymer obtained by polycond...

Embodiment 2

[0033] At first, methyl glycolate copolymer adopts following method to prepare:

[0034]100 mol of methyl glycolate, 0.2 mol of adipic acid, and 0.2 mol of butanediol were added to the polymerization reactor, and precondensation was carried out at a stirring speed of 150 rpm and in the presence of a polymerization catalyst. Wherein, the polymerization catalyst is a mixture prepared by titanium isopropoxide and taurine in a mass ratio of 2:1, and the amount of the polymerization catalyst is 0.1% of the total mass of methyl glycolate. The precondensation temperature is 130-190° C., the reaction time is 8 hours, and the precondensation product is obtained. Under the stirring condition of 150 rev / min, the polycondensation product is subjected to polycondensation reaction to prepare methyl glycolate copolyester, the polycondensation temperature is 180-235° C., the reaction time is 12 hours, and the vacuum degree is 0.1-100 mmHg. The methyl glycolate copolymer obtained by polyconde...

Embodiment 3

[0037] At first, methyl glycolate copolymer adopts following method to prepare:

[0038] 100 mol of methyl glycolate, 0.2 mol of adipic acid, and 0.2 mol of butanediol were added to the polymerization reactor, and precondensation was carried out at a stirring speed of 150 rpm and in the presence of a polymerization catalyst. Wherein, the polymerization catalyst is a mixture prepared by titanium isopropoxide and taurine in a mass ratio of 2:1, and the amount of the polymerization catalyst is 0.1% of the total mass of methyl glycolate. The precondensation temperature is 130-190° C., the reaction time is 10 hours, and the precondensation product is obtained. Under the stirring condition of 150 rpm, the polycondensation product is subjected to polycondensation reaction to prepare methyl glycolate copolyester, the polycondensation temperature is 180-235° C., the reaction time is 15 hours, and the vacuum degree is 0.1-100 mmHg. The methyl glycolate copolymer obtained by polycondens...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com