PDO powder and preparation method thereof

A powder and powder bottle technology, applied in the field of medical cosmetology, can solve the problems of non-degradation, rejection of price, existence of immunity, etc., and achieve the effects of good effect, small tissue reaction, and high strength retention rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) dissolving p-dioxanone and L-polylactic acid in hexafluoroisopropanol solvent according to the mass and number ratio of 8:2 to obtain a polymer organic solution;

[0033] (2) The polymer organic solution prepared in step (1) is stirred with the polymer organic solution and polyvinyl alcohol aqueous solution to obtain an emulsion, stirred at a high speed in an emulsion machine, and distilled for 1.5h under 1MPa conditions to prepare get a suspension;

[0034] (3) centrifuging the suspension in step (2), washing and drying with 70% ethanol to obtain PDO microsphere powder, and the particle size of the PDO microsphere powder is 250 microns;

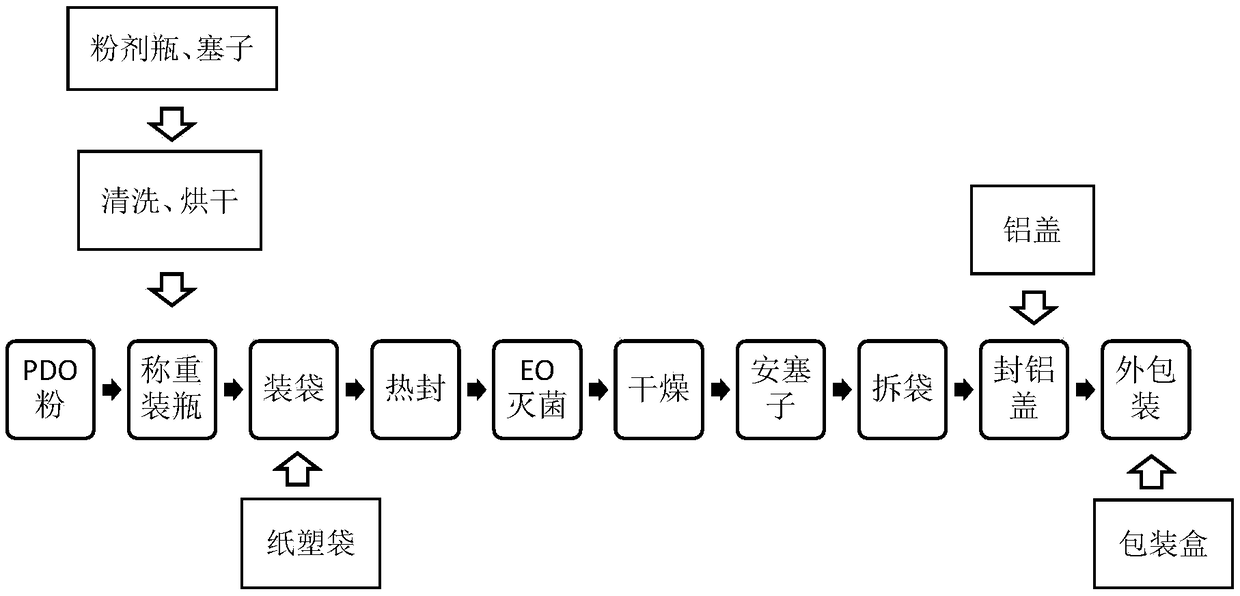

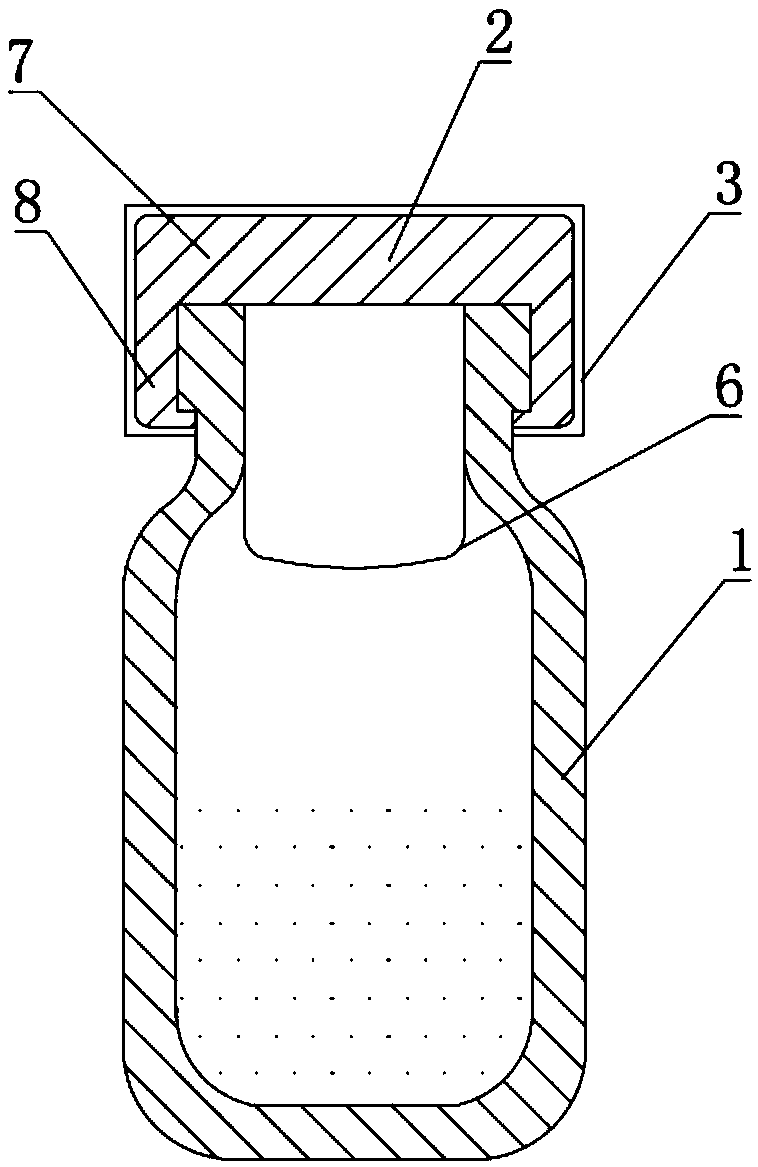

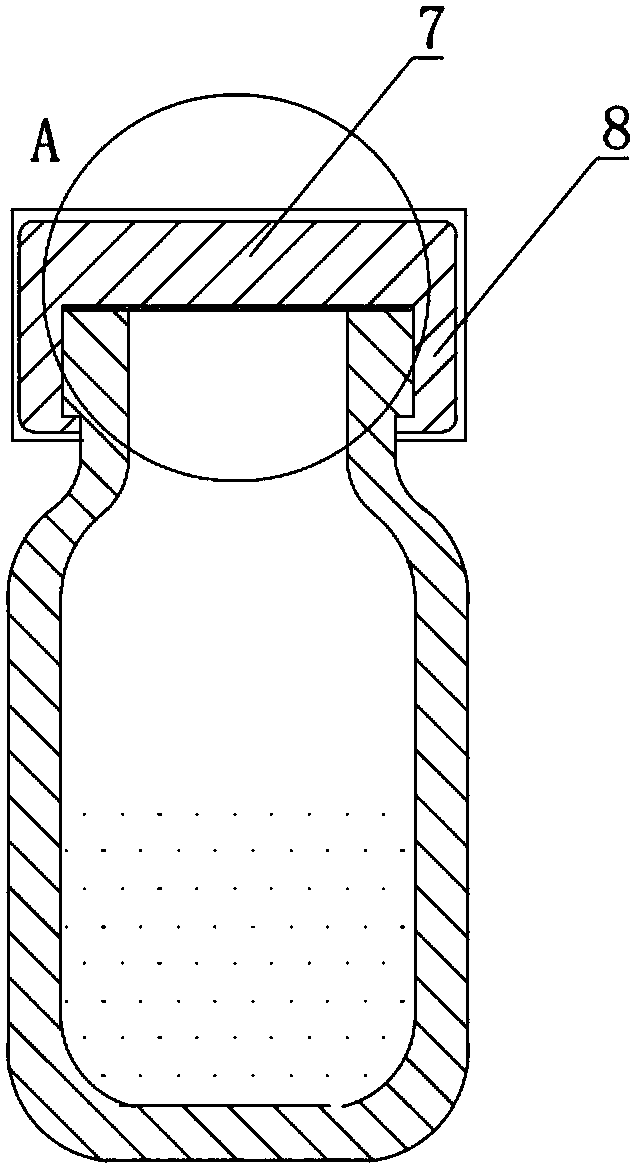

[0035] (4) Wash the powder bottle and stopper with distilled water, dry, put the prepared PDO microsphere powder into the powder bottle, heat-seal the Tyvek paper on the inner wall of the powder bottle by using a special heating tool, sterilize with EO, and dry Finally, the stopper is directly plugged in the mouth of the powder b...

Embodiment 2

[0037] (1) Dissolving p-dioxanone and polycaprolactone in a hexafluoroisopropanol solvent according to the mass and number ratio of 8:4 to obtain a polymer organic solution;

[0038] (2) Stir the polymer organic solution prepared in step (1) with the polyvinyl alcohol aqueous solution to obtain an emulsion, stir at a high speed in an emulsion machine, and distill for 1.25h under the condition of 1.25MPa, Prepare a suspension;

[0039] (3) The suspension in step (2) is centrifuged, washed and dried with 78% ethanol to obtain a PDO microsphere powder, and the particle size of the PDO microsphere powder is 125 microns;

[0040] (4) Wash the powder bottle and stopper with distilled water, dry, put the prepared PDO powder into the powder bottle, place the Tyvek paper horizontally at the mouth of the powder bottle, and its edge should be longer than the mouth of the powder bottle diameter, using a flat heat sealer to heat seal the Tyvek paper on the mouth of the powder bottle, then...

Embodiment 3

[0042](1) Dissolving p-dioxanone and polyglycolic acid in hexafluoroisopropanol solvent according to the mass and number ratio of 8:5 to obtain a polymer organic solution;

[0043] (2) Stir the polymer organic solution prepared in step (1) with the polyvinyl alcohol aqueous solution to obtain an emulsion, stir at a high speed in an emulsion machine, and distill for 1.5h under the condition of 1.5MPa, Prepare a suspension;

[0044] (3) centrifuging the suspension in step (2), washing and drying with 85% ethanol to obtain PDO microsphere powder, and the particle size of the PDO microsphere powder is 5 microns;

[0045] (4) Wash the powder bottle and stopper with distilled water, dry, and put the PDO powder into the powder bottle. The edge of the Tyvek paper should be longer than the diameter of the mouth of the powder bottle. Heat seal on the mouth of the powder bottle, use EO to sterilize, after sterilization, place the powder bottle on a 100-grade clean bench, remove the Tyve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com