Waste foam plastic sandwich decoration and insulation composite wall and preparation method thereof

A composite technology of foam plastics and thermal insulation, which is applied in construction, building structure, covering/lining, etc., can solve the problems of unstable fixing of thermal insulation boards, affecting the overall performance of the wall, and inconvenient construction operations, etc., and achieves high knot strength , resource saving and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

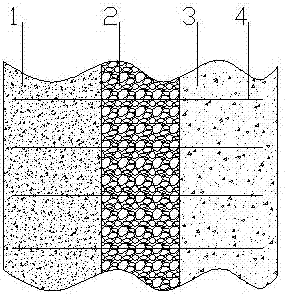

[0030] Such as figure 1 Shown is a waste foam plastic sandwich decorative insulation composite wall, including a load-bearing inner leaf wall 1, a non-load-bearing outer leaf wall 3, and waste foam poured between the load-bearing inner leaf wall 1 and the non-load-bearing outer leaf wall 3 The plastic insulation layer 2, and the connection tie rod 4 that connects the load-bearing inner leaf wall 1, the non-load-bearing outer leaf wall 3, and the waste foam plastic insulation layer 2 into one.

[0031] The load-bearing inner leaf wall 1 is made of load-bearing materials that can withstand relatively high pressure. The waste foam plastic insulation layer 2 includes waste foam plastic particles, cement, chopped fibers, styrene-acrylic emulsion, concrete waterproofing agent, hydrogen peroxide and water mixed together for foami...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com