Ceramic tile back-laying structural nail

A brick back and porcelain technology, applied in the field of architectural decoration, to achieve the effect of improving bond firmness, reliable construction principle, and controlling shedding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Below, the substantive features and advantages of the present invention will be further described in conjunction with examples, but the present invention is not limited to the listed examples.

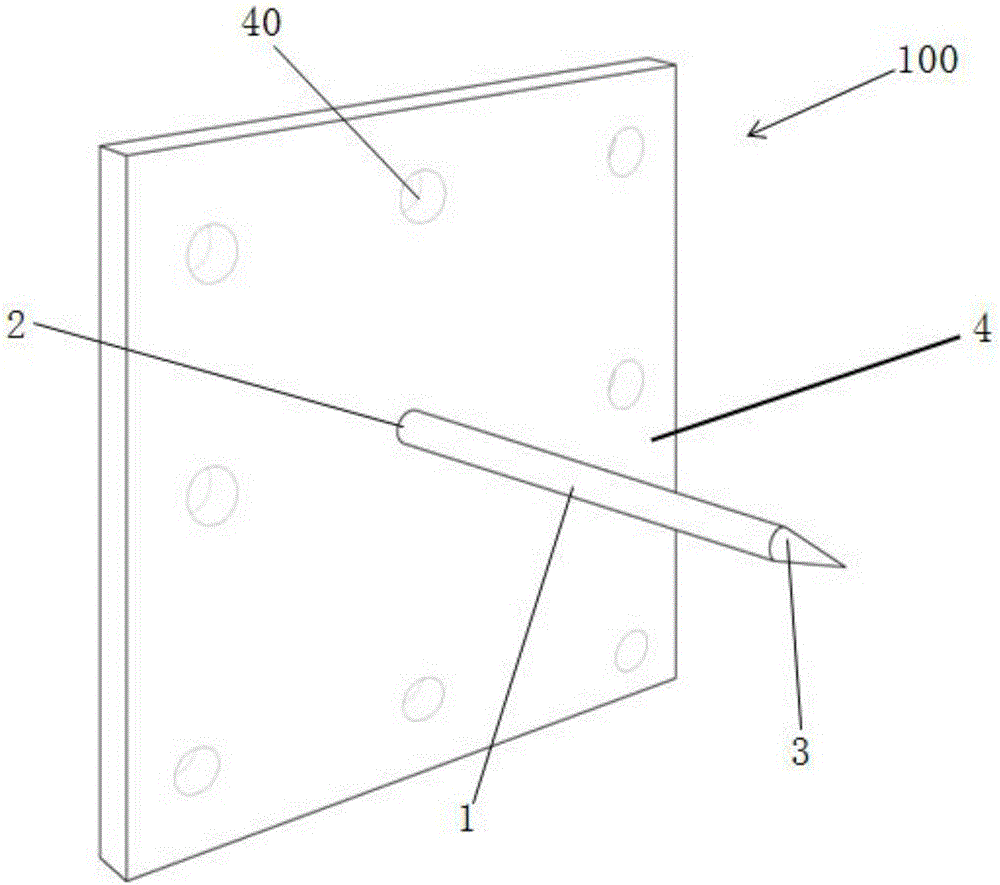

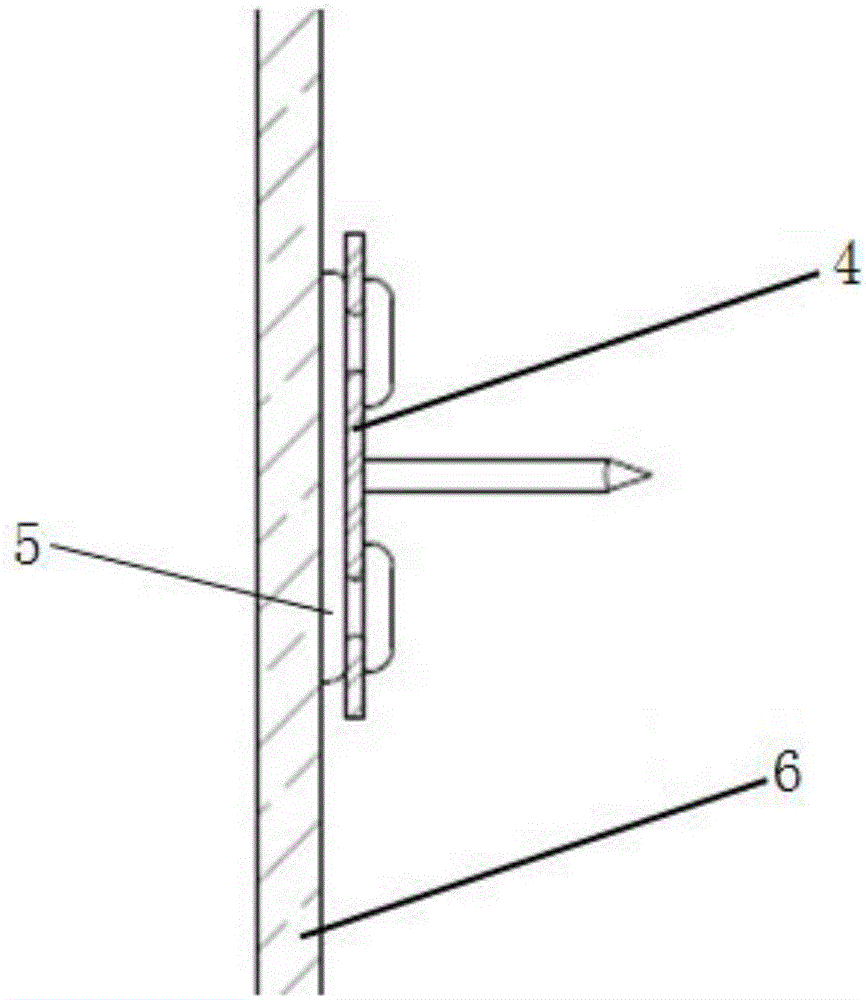

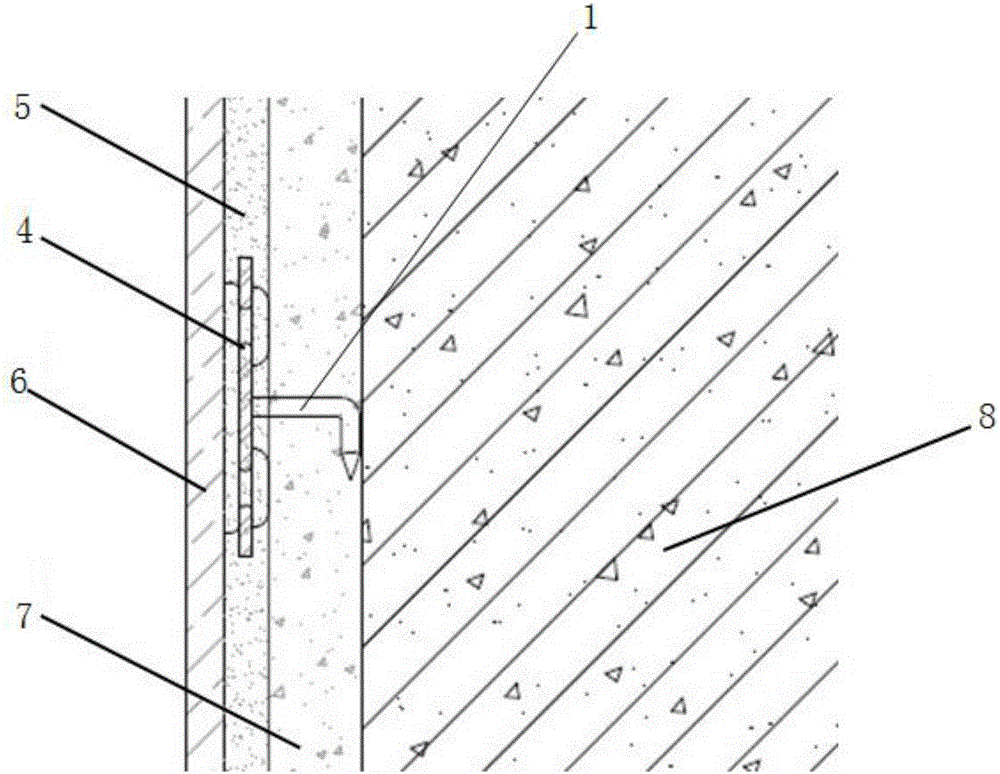

[0015] Such as Figure 1 to Figure 4 As shown, the structural nail 100 for back-mounted porcelain tiles in this embodiment includes a nail body 1 , a nail tail 2 and a nail head 3 , and the nail tail 2 is provided with an iron sheet 4 . The nail body 1 is iron wire, and the iron sheet 4 is provided with a plurality of fixing holes 40, and the iron sheet 4 is fixed on the back of the porcelain tile 6 through the structural glue 5, and the structural glue 5 passes through the fixing holes 40. The structural nails are bonded to the wall body 8 through the fixing layer 7 . The above technical proposal can improve the bonding firmness between the porcelain tiles and the wall surface, has a reliable construction principle and a simple construction process, and improves the constructi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com