Nano high-gloss moistureproof impregnated paper and preparation method thereof

A technology of impregnated paper and nano, which is applied in the field of impregnated paper, which can solve the problems of reducing the service life of impregnated paper, reducing the aesthetics of impregnated paper, and insufficient surface gloss, so as to achieve good surface gloss, high gloss and shiny effect, and not easy to be affected by moisture The effect of damage mass

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

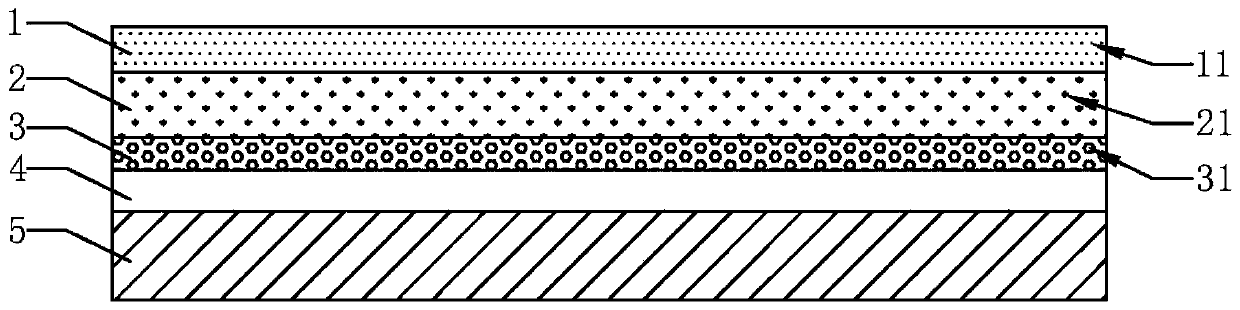

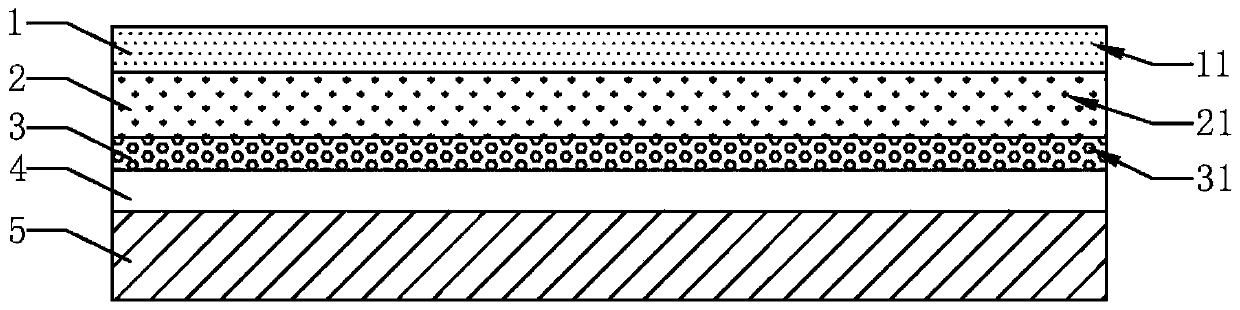

[0062] A nano high-gloss moisture-proof impregnated paper, the impregnated paper includes a wear-resistant layer 1, a high-gloss hydrophobic layer 2, an anti-penetration adhesive layer 4 and a base paper layer 5 arranged sequentially from top to bottom, and the base paper layer 5 is printed with a pattern. The high-gloss hydrophobic layer 2 is made of organic silica gel embedded with nano-alumina particles 21 .

[0063] The impregnated paper also includes a flash layer 3, the upper surface of the flash layer 3 is adhesively connected to the lower surface of the high-gloss hydrophobic layer 2, and the lower surface of the flash layer 3 is bonded to the upper surface of the anti-penetration film layer. joint connection; the flash layer 3 is made of melamine glue embedded with nano-pearl powder 31.

[0064] The particle size of the nano-alumina particles 21 is 15-30nm, and the distribution density of the nano-alumina particles 21 in the organic silica gel layer is 40-70 pieces / cm...

Embodiment 2

[0091] The difference between this embodiment and above-mentioned embodiment 1 is:

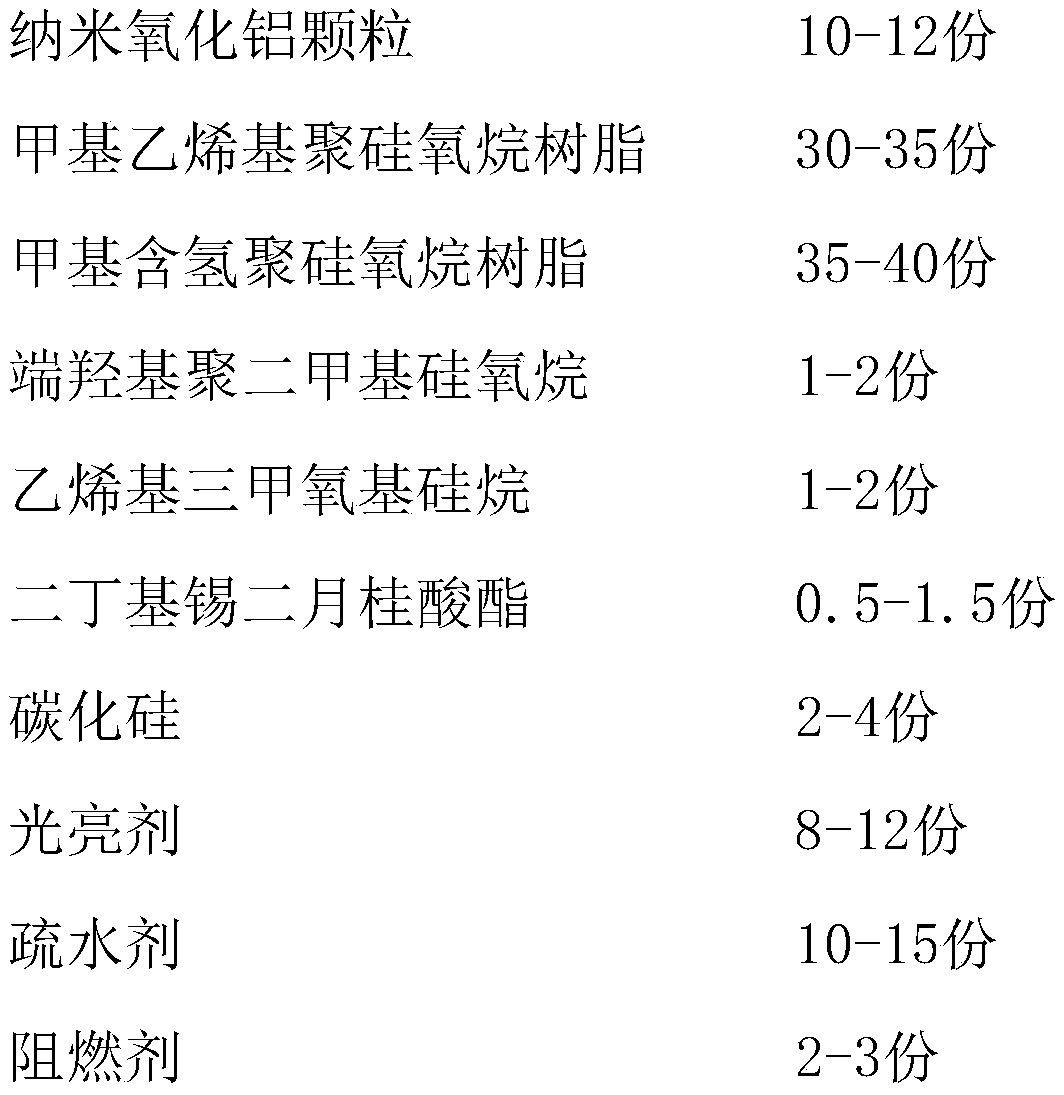

[0092] Described organosilica gel is made from the raw material of following weight part:

[0093]

[0094] Described organosilica gel is made by following steps:

[0095] Step A: According to parts by weight, premix methyl vinyl polysiloxane resin, methyl hydrogen polysiloxane resin and hydroxyl-terminated polydimethylsiloxane at a speed of 700rpm and a temperature of 28°C Under the condition of stirring for 23min, material A was obtained;

[0096] Step B: In parts by weight, vinyltrimethoxysilane and dibutyltin dilaurate are respectively added to the material A prepared in step A, and stirred while adding at a speed of 1050 rpm. After the addition of the materials is completed, the Stirring for 34 minutes at a rotational speed of 1850 rpm to obtain material B;

[0097] Step C, mixing and stirring silicon carbide, brightener, hydrophobic agent and flame retardant according to parts by w...

Embodiment 3

[0118] The difference between this embodiment and above-mentioned embodiment 1 is:

[0119] Described organosilica gel is made from the raw material of following weight part:

[0120]

[0121] Described organosilica gel is made by following steps:

[0122] Step A: According to parts by weight, premix methyl vinyl polysiloxane resin, methyl hydrogen polysiloxane resin and hydroxyl-terminated polydimethylsiloxane at a speed of 800rpm and a temperature of 25°C Under the condition of stirring for 20min, material A was obtained;

[0123] Step B: In parts by weight, vinyltrimethoxysilane and dibutyltin dilaurate were added to the material A prepared in step A respectively, and stirred while adding at a rotating speed of 1100 rpm. After the addition of the materials, the Stirring for 33 minutes at a rotational speed of 1900 rpm to obtain material B;

[0124] Step C, mixing and stirring silicon carbide, brightener, hydrophobic agent and flame retardant according to parts by weig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com