Preparation method of wear-resistant polyurethane elastomer for polyurethane screen

A technology of polyurethane elasticity and polyurethane, which is applied in the field of preparation of wear-resistant polyurethane elastomers for polyurethane screens, can solve the problems of shortened life of polyurethane screens, increased wear, and increased temperature, and achieves enhanced elastic deformation, increased tensile strength, and improved The effect of abrasion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

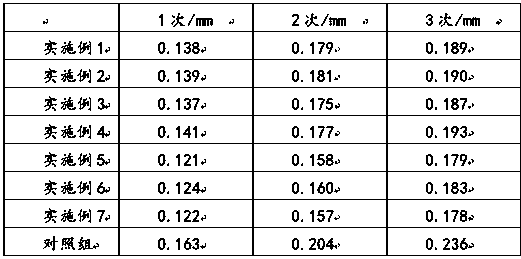

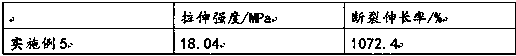

Examples

Embodiment 1

[0022] A method for preparing wear-resistant polyurethane elastomers for polyurethane screens. Mix 1,4-cyclohexyl-diisocyanate and polytetrahydrofuran into a reaction kettle, stir at a speed of 200r / min for 10min, then add epoxy, and heat To 60°C, stir and react at 200r / min for 0.5 hours, then add dibutyltin dilaurate, and perform ultrasonic treatment for 15 minutes, the ultrasonic frequency is 30kHz, power is 550W, and then continue to react for 1.5 hours, after standing for 10 minutes Then add a chain extender, adjust the temperature to 70°C, and carry out the chain extension reaction for 2 hours, that is, the chain extender is 2-methyl-1,3-propanediol, and the 2-methyl-1,3-propanediol The mass ratio to 4,4-diphenylmethane diisocyanate is 5:1. The mixing mass ratio of the 4,4-diphenylmethane diisocyanate and polytetrahydrofuran is 5:1, the molar ratio of the epoxide to the 4,4-diphenylmethane diisocyanate is 1:10, and the dilaurate The molar ratio of dibutyltin dibutyltin t...

Embodiment 2

[0024] A method for preparing wear-resistant polyurethane elastomers for polyurethane screens. Mix 1,4-cyclohexyl-diisocyanate and polytetrahydrofuran into a reaction kettle, stir at a speed of 200r / min for 10min, then add epoxy, and heat To 64°C, stir and react at 200r / min for 0.5 hours, then add dibutyltin dilaurate, and perform ultrasonic treatment for 20min. Then add a chain extender, adjust the temperature to 75°C, and carry out the chain extension reaction for 2 hours, that is, the chain extender is 2-methyl-1,3-propanediol, and the 2-methyl-1,3-propanediol The mass ratio to 4,4-diphenylmethane diisocyanate is 5:1. The mixing mass ratio of the 4,4-diphenylmethane diisocyanate and polytetrahydrofuran is 5:1.5, the molar ratio of the epoxide to the 4,4-diphenylmethane diisocyanate is 1:13, and the dilaurate The molar ratio of dibutyltin dibutyltin to polytetrahydrofuran is 25:1. The epoxide is propylene oxide.

Embodiment 3

[0026] A method for preparing wear-resistant polyurethane elastomers for polyurethane screens. Mix 1,4-cyclohexyl-diisocyanate and polytetrahydrofuran into a reaction kettle, stir at a speed of 200r / min for 10min, then add epoxy, and heat To 62°C, stir and react at 200r / min for 0.5 hours, then add dibutyltin dilaurate, and perform ultrasonic treatment for 18min, the ultrasonic frequency is 30kHz, power is 550W, then continue to react for 1.6 hours, after standing for 10min Then add a chain extender, adjust the temperature to 72°C, and carry out the chain extension reaction for 2 hours, that is, the chain extender is 2-methyl-1,3-propanediol, and the 2-methyl-1,3-propanediol The mass ratio to 4,4-diphenylmethane diisocyanate is 5:1. The mixing mass ratio of the 4,4-diphenylmethane diisocyanate and polytetrahydrofuran is 5:1.2, the molar ratio of the epoxide to the 4,4-diphenylmethane diisocyanate is 1:12, and the dilaurate The molar ratio of dibutyltin dibutyltin to polytetrah...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com