Composite material for repairing non-excavated pipeline and preparation method thereof

A composite material and pipeline repair technology, applied in the directions of reagents, educts, products, etc., can solve the problems of unstable repair effect, high pipeline repair cost, and troublesome construction unit selection of pipeline repair materials, so as to achieve low cost and improve mechanical performance. , the effect of short process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

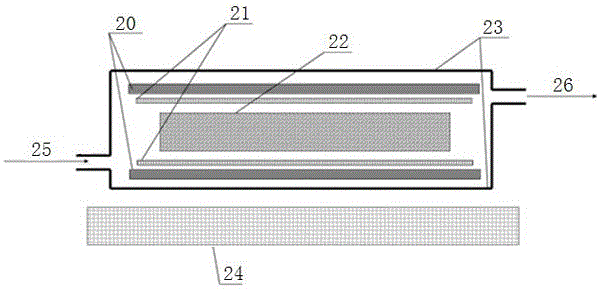

[0036] The preparation method of the composite material for trenchless pipeline repair of the present invention has the following process flow: polyester needle-punched nonwoven fabric → hot pressing forming process → VARI forming process → composite material for pipeline repair.

[0037] 1. Hot pressing forming process:

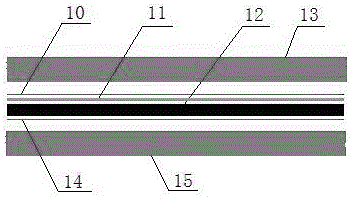

[0038] Put the polyester needle-punched nonwoven fabric and TPU into the mold according to a certain ratio, and perform hot-press molding under certain conditions to obtain a reinforced fabric. The schematic diagram of the hot-press molding process is as follows figure 1 shown.

[0039] 1.1. Raw material selection:

[0040] The present invention uses 1 layer of polyester needle-punched nonwoven fabric and 2 layers of thermoplastic spandex elastomer (TPU) for thermal compression compounding, wherein:

[0041] Polyester needle-punched nonwoven fabric: the square meter weight is 448g / m 2 , The thickness is 3.30mm, the fracture stress in warp and weft directi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Weight | aaaaa | aaaaa |

| Elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com