Inner spiral unit

An internal helix and helix technology, applied in the field of internal helix units, can solve the problems of inability to set up and use the structure design of single leaf and compound leaves, breakage of compound leaves, leakage and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

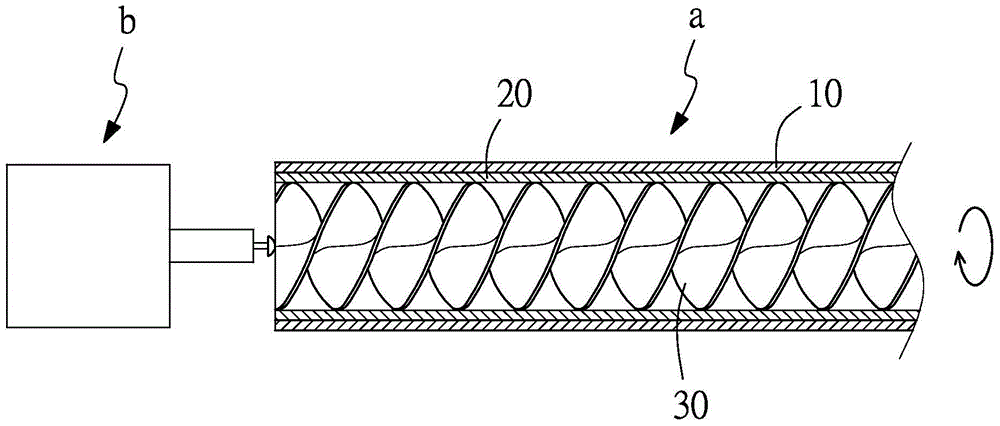

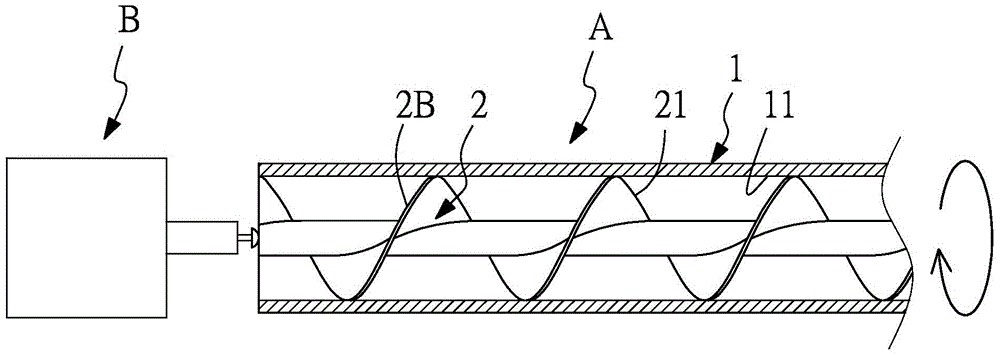

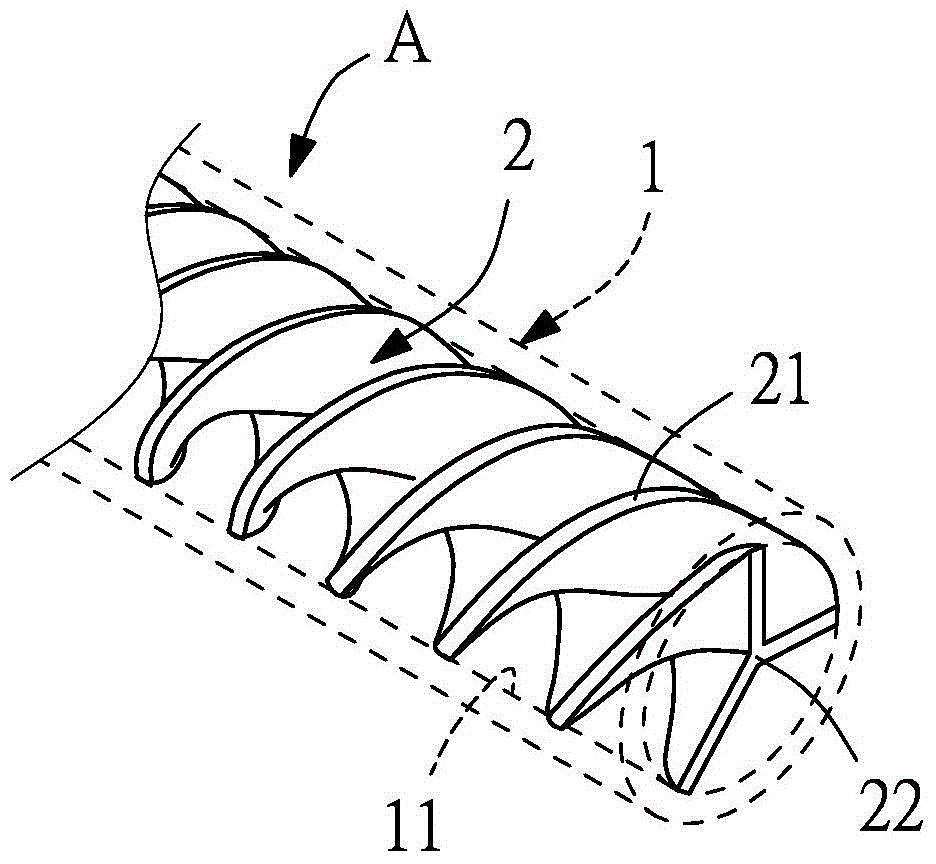

[0038] Such as figure 2 As shown, the present invention refers to an internal spiral unit, which mainly includes a spiral pipe A, and is powered by a power source B in addition, wherein:

[0039] The spiral pipe fitting A comprises a hollow pipe body 1 and a helical blade 2 (such as figure 2 , 3 ), the hollow pipe body 1 has an inner wall surface 11, and the hollow pipe body 1 can be composed of several pipe sections 1A fixedly connected (another example Figure 4 ), and the helical blade 2 can also be composed of several blade segments 2A fixedly connected. The outer edge of the helical blade 2 is an outer edge 21, and the outer edge 21 and the inner wall surface 11 of the hollow pipe body 1 appear to be seamlessly affixed (also as the first Figure 5-7 , Figures 5A-7A ), so that when the hollow pipe body 1 or the helical blade 2 is rotated, they can all rotate synchronously.

[0040] The power source B can directly actuate the rotation of the screw blade 2 (such as ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com