Preparation method for marinated pig knuckle

A production method and the technology of stewed pork knuckle are applied in the processing of pork knuckles and the production of stewed pork knuckles, which can solve the problems of shortened product shelf life, insufficient chewiness, and long sterilization time, so as to improve the taste and sliceability, and improve the quality of the product. The effect of the yield rate and the short cycle of the production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Embodiment 1 A kind of preparation method of stewed elbow

[0044] The preparation method of stewed elbow in the present embodiment is carried out according to the following steps:

[0045] ⑴Material selection and renovation

[0046] Remove hair stains, blood stains, lesions, and bone fragments from raw pig knuckles that have passed the purchase inspection, and repair them, take 100kg, and get A;

[0047] (2) Tumble and marinate

[0048] (21) tumble

[0049] Put A, 2kg of salt and 15kg of water into the tumbler, the vacuum degree is 0.1MPa, the tumbling is intermittent tumbling, each tumbling cycle includes tumbling for 40 minutes, and stops for 20 minutes, so repeat until 5 tumbling cycles are completed , that is, the effective total time of rolling and kneading is 240 minutes, and each stop is also necessary, and B1 is obtained;

[0050] (22) Pickled

[0051] Take B1 out and put it in a pickling container, pickle at 0°C for 16 hours, shape and arrange to get B2; ...

Embodiment 2-5

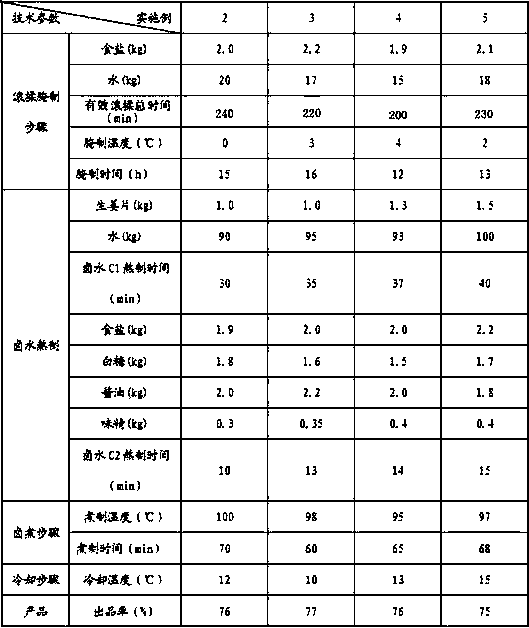

[0061] Embodiment 2-5 The preparation method of stewed elbow

[0062] Embodiments 2-5 are respectively a method for making stewed elbows. The manufacturing process is the same as that of Embodiment 1, except that the corresponding technical parameters in the manufacturing process are different. See Table 1 for specific parameters.

[0063]

[0064] The stewed pork elbow made in the above examples is elastic, and the texture, taste and cross-section of the meat are good. The brine is boiled in two steps. The boiled brine makes the surface and internal flavor of the boiled product uniform and stable in quality. , uniform hair color, strong and long-lasting fragrance, excellent slice. The production cycle is short, the juice loss of the elbow is less, the yield rate of the product is ≥75%, and the shelf life is long.

Embodiment 6-7

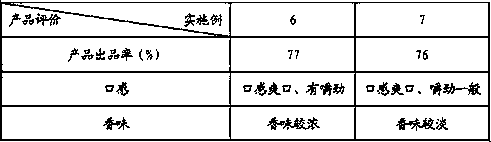

[0065] Example 6-7 The influence of brine boiling steps on the flavor and quality of stewed elbow products

[0066] The stewed brine of the present invention adopts a two-step method, the first step is to boil the spice water, and the second step is to prepare the flavor and taste of the spice water before boiling. Traditional brine cooking is to boil all the seasonings together, and different cooking steps have an impact on the flavor and quality of the final product.

[0067] This embodiment explores the steps of boiling brine. Other production steps and ingredients in the brine boiling process and the addition amount of each ingredient are the same as in Example 1. The only difference is that the brine boiled in Example 6 The steps are the same as those in Example 1. In Example 7, the brine is boiled in one step, that is, all the seasonings are boiled together. The specific results are shown in Table 2.

[0068]

[0069] As can be seen from the above examples, the bri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com