Preparation method of cellulose/metal oxide composite aerogel

A technology of composite aerogel and cellulose, applied in the field of preparing cellulose composite metal oxide aerogel, can solve the problems of low strength of metal oxide aerogel, achieve high mechanical strength and toughness, low porosity, High toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

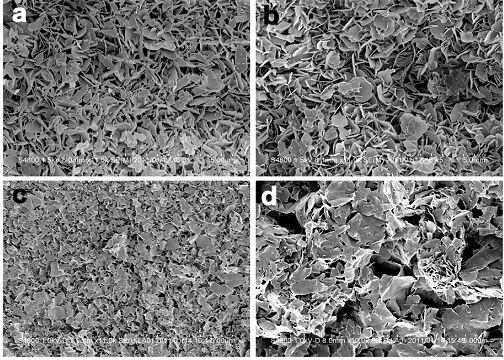

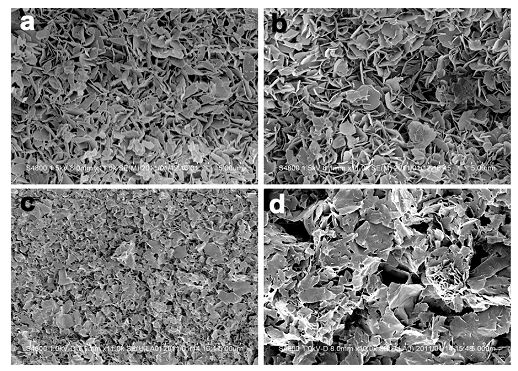

Image

Examples

Embodiment 1

[0029] Firstly, the LiOH / urea (7wt% / 12wt%, wt% represents the mass percent) solution was cooled to -12°C, and then the natural cellulose raw material with a degree of polymerization of 500 was put into it, and the natural cellulose was rapidly stirred by mechanical stirring at room temperature. Dissolved to obtain a 4wt% cellulose solution. After the solution was centrifugally degassed, it was coated on a glass plate by casting method, then immersed in a 5wt% sulfuric acid solution to solidify and regenerate, and finally washed with water to obtain regeneration. Cellulose film.

[0030] The cellulose membrane is washed with water to remove inorganic salts and other impurities, and then the water in it is gradually replaced with methanol solvent. Immerse it in 50 mL of CoCl 2 Concentration is 0.0126 mol / L methanol solution, add 10ml ethylene oxide at the same time, after standing at 20 ℃ for 2 hours, a tan composite cellulose gel film is obtained. The composite gel membrane w...

Embodiment 2

[0032] The cellulose film was obtained by dissolving the natural cellulose with a degree of polymerization of 500 in NaOH / urea (7wt% / 12wt%) solvent system, and the method was the same as in Example 1.

[0033] The cellulose membrane is washed with water to remove inorganic salts and other impurities, and then the water therein is gradually replaced with ethanol solvent. Immerse it in 50 mL of CoCl 2 Concentration is 0.0084 mol / L methanol solution, add 10ml propylene oxide at the same time, after standing at 40 ℃ for 24 hours, a tan composite cellulose gel film is obtained. The composite gel membrane was first washed several times with deionized water, and then the water in the composite membrane was replaced with ethanol. The composite airgel of cellulose / cobalt oxide was obtained by supercritical drying.

Embodiment 3

[0035]The cellulose film was obtained by dissolving the natural cellulose with a degree of polymerization of 500 in NaOH / urea (7wt% / 12wt%) solvent system, and the method was the same as in Example 1.

[0036] The cellulose membrane is washed with water to remove inorganic salts and other impurities, and then the water in it is gradually replaced with methanol solvent. Immerse it in 50 mL of CoCl 2 Concentration is 0.0168 mol / L methanol solution, add 10ml propylene oxide at the same time, after standing at 40 ℃ for 36 hours, a tan composite cellulose gel film is obtained. The composite gel membrane was first washed several times with deionized water, and then the water in the composite membrane was replaced with methanol. The composite airgel of cellulose / cobalt oxide was obtained by supercritical drying.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com