High-fluidity low-smoke zero-halogen flame retardant polyolefin composite and preparation method thereof

A composite material and high fluidity technology, applied in the field of high fluidity low smoke halogen free flame retardant polyolefin composite material and its preparation, thermoplastic halogen free flame retardant composite material, can solve the problem of reduced flame retardancy, flow processing of composite materials Performance degradation, low melt mass flow rate, etc., to achieve the effect of good fluidity and flame retardant performance, excellent UV resistance, and improved processing flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

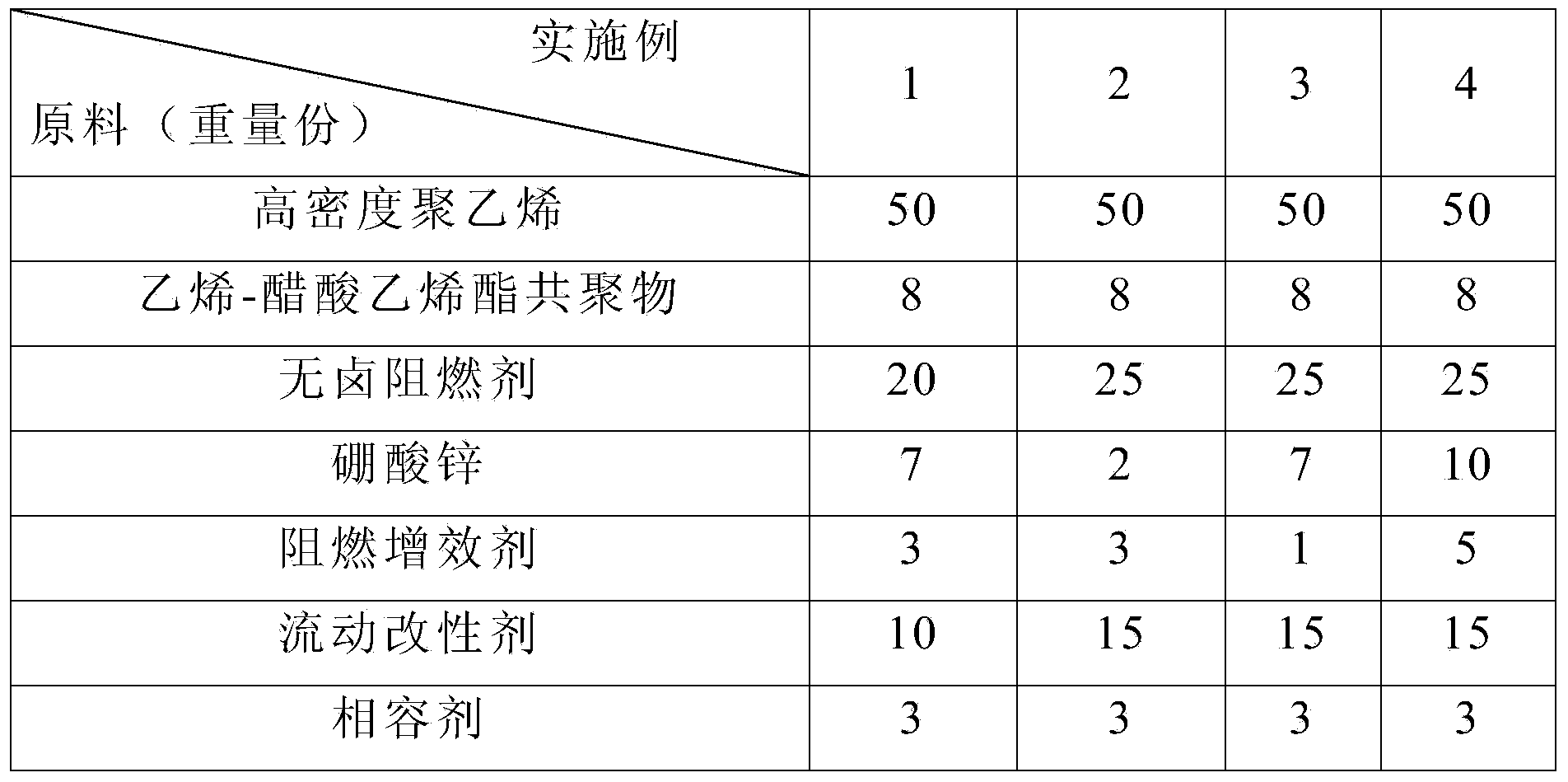

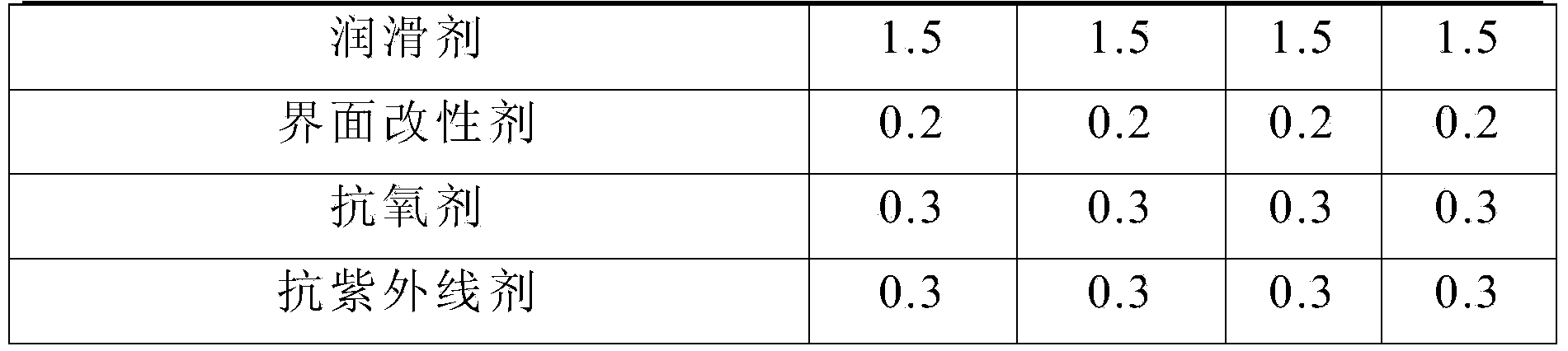

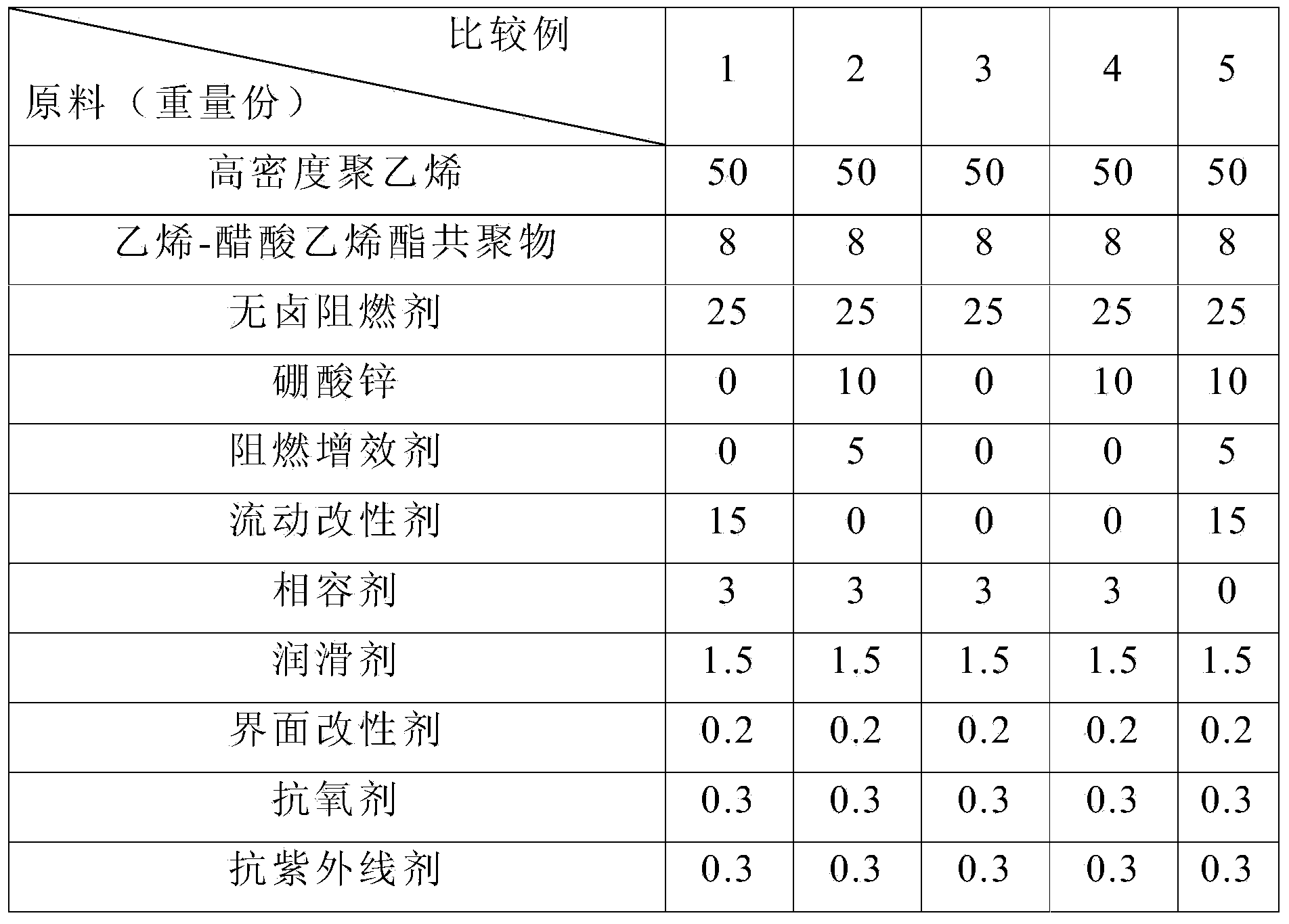

Embodiment 1

[0042] Weigh all the raw materials according to the weight ratio of Example 1 in Table 1, put them into a low mixer and mix them for 5 minutes at a temperature of 40°C; after the materials are mixed evenly, discharge them, put them into a parallel co-rotating twin-screw machine for extrusion and granulation , the temperature of each section of the screw is: feeding section 130°C, conveying section 150°C, melting section 190°C, head 185°C, host speed 18rpm, feeding speed 14rpm; then water cooling, pelletizing, and drying to obtain composite materials.

Embodiment 2

[0044] Weigh all the raw materials according to the weight ratio of Example 2 in Table 1, put them into a low mixer and mix them for 8 minutes at a temperature of 45°C; after the materials are mixed evenly, discharge them, put them into a parallel co-rotating twin-screw machine for extrusion and granulation , the temperature of each section of the screw is: feeding section 135°C, conveying section 160°C, melting section 185°C, head 180°C, host speed 20rpm, feeding speed 15rpm; then water cooling, pelletizing, and drying to obtain composite materials.

Embodiment 3

[0046] Weigh all the raw materials according to the weight ratio of Example 3 in Table 1, put them into a low mixer and mix them for 8 minutes at a temperature of 45°C; after the materials are mixed evenly, discharge them, put them into a parallel co-rotating twin-screw machine for extrusion and granulation , the temperature of each section of the screw is: feeding section 140°C, conveying section 170°C, melting section 185°C, head 185°C, host speed 22rpm, feeding speed 16rpm; then water cooling, pelletizing, and drying to obtain composite materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com