Carbon nanotube compound film and preparation method thereof

A carbon nanotube composite, carbon nanotube technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of limited types, complex preparation methods, easy to break, etc., to achieve good mechanical strength and toughness, preparation method Simple, evenly grown results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The carbon nanotube composite film and its preparation method of the technical solution will be described in detail below in conjunction with the accompanying drawings.

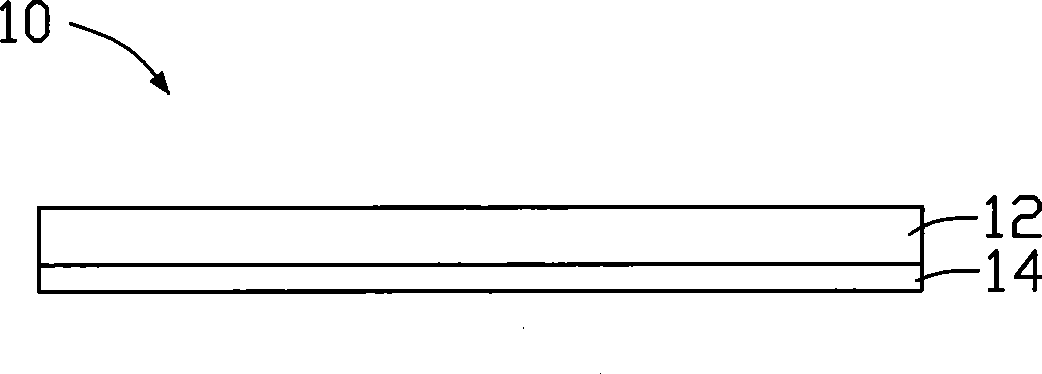

[0023] see figure 1 , the first embodiment of the technical solution provides a carbon nanotube composite film 10, the carbon nanotube composite film 10 is a double-layer structure, including: a matrix material layer 12 and a carbon nanotube layer 14, the carbon nanotube The tube layer 14 is a self-supporting structure composed of multiple carbon nanotubes, and the multiple carbon nanotubes are parallel to the base material layer 12 . The carbon nanotube layer 14 is tightly bonded to the matrix material layer 12 by van der Waals force. The carbon nanotubes in the double-layered carbon nanotube film 10 are aligned in isotropy or in a fixed direction or in different directions.

[0024] The thickness of the above-mentioned carbon nanotube layer 14 is 1 micron to 1 millimeter, and the thickness of the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com