Liner structure of carbon nano tube and preparation method thereof

A technology of carbon nanotube structure and carbon nanotube wire, which is applied in the field of carbon nanotube linear structure and its preparation, can solve the problems of difficulty in obtaining silicon wafers and limiting the practical application of nanofiber yarn, and achieve good mechanical strength and toughness Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

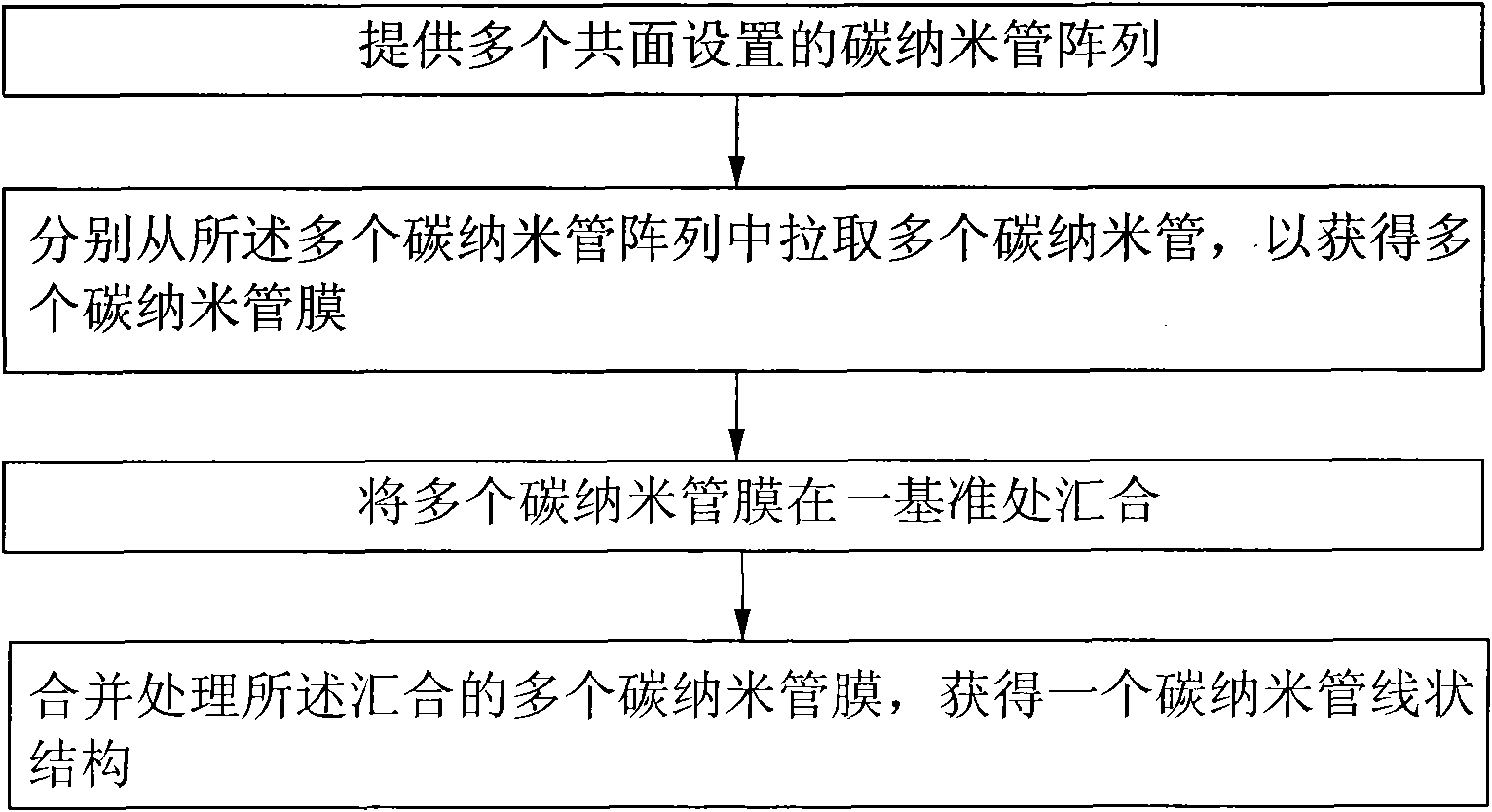

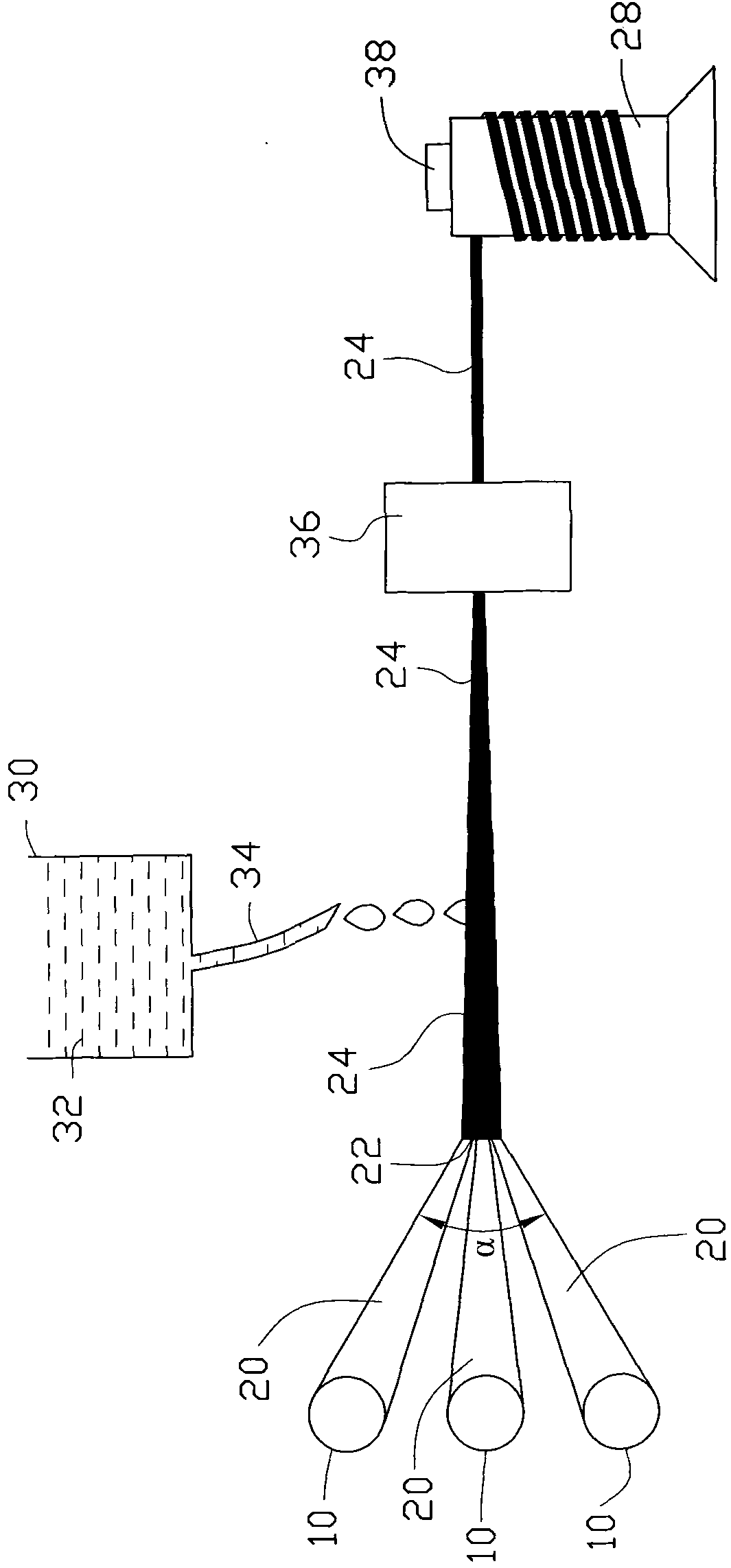

[0014] Please also refer to figure 1 , figure 2 and image 3 , the first embodiment of the present invention provides a method for preparing a carbon nanotube linear structure, the preparation method mainly includes the following steps:

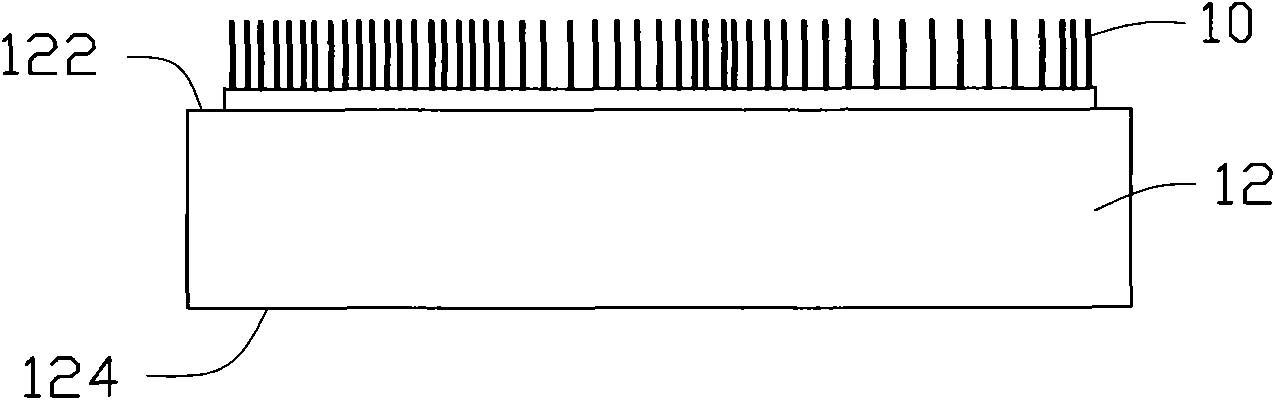

[0015] Step S 101 : providing a plurality of carbon nanotube arrays 10 coplanarly arranged.

[0016] Specifically, the plurality of carbon nanotube arrays 10 are respectively formed on a plurality of substrates 12 . The plurality of bases 12 respectively have a first surface 122 and a second surface 124 opposite to the first surface 122 . The carbon nanotube array 10 is grown on the first surface 122 of each substrate 12 . The second surfaces 124 of each base 12 are fixedly disposed on the same plane. The plurality of substrates 12 formed with the carbon nanotube arrays 10 can be arranged in a straight line, arc, zigzag or other shapes in a plane. The number of the substrate 12 formed with the carbon nanotube array 10 is not limited. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com