Preparation method of optical-actuated composite film, optical-actuated composite film and optical actuator

A composite thin film and light-actuated technology, which is applied in the direction of mechanical power generation mechanisms, mechanical equipment, machines/engines, etc., can solve problems such as restricting the application of actuators, difficult integration, and reduced sensitivity of actuators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] The invention provides a method for preparing a light-activated composite thin film. Double layers of the prepared light-activated composite thin film are closely connected through chemical bonds, and have high mechanical strength and light-activated response speed. In other words, the present invention provides a flexible light-activated nanocomposite bilayer film structure based on interface optimization. The invention also provides a photoactuator prepared with the composite double-layer film, such as an intelligent driver and the like.

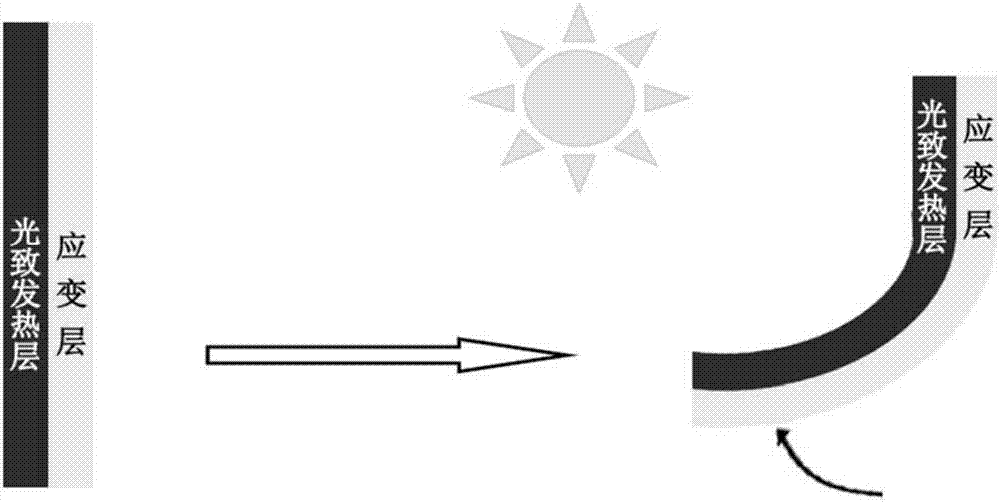

[0036] Photoactivated composite films generally consist of a photothermal layer and a flexible strain layer. The photothermal layer generates heat after absorbing light, so that the flexible strain layer is also heated. When heated, the composite film will bend due to the difference in the coefficients of thermal expansion of the two layers. Its working status can be as follows figure 1 Suggested.

[0037] In one embodiment of t...

Embodiment 1

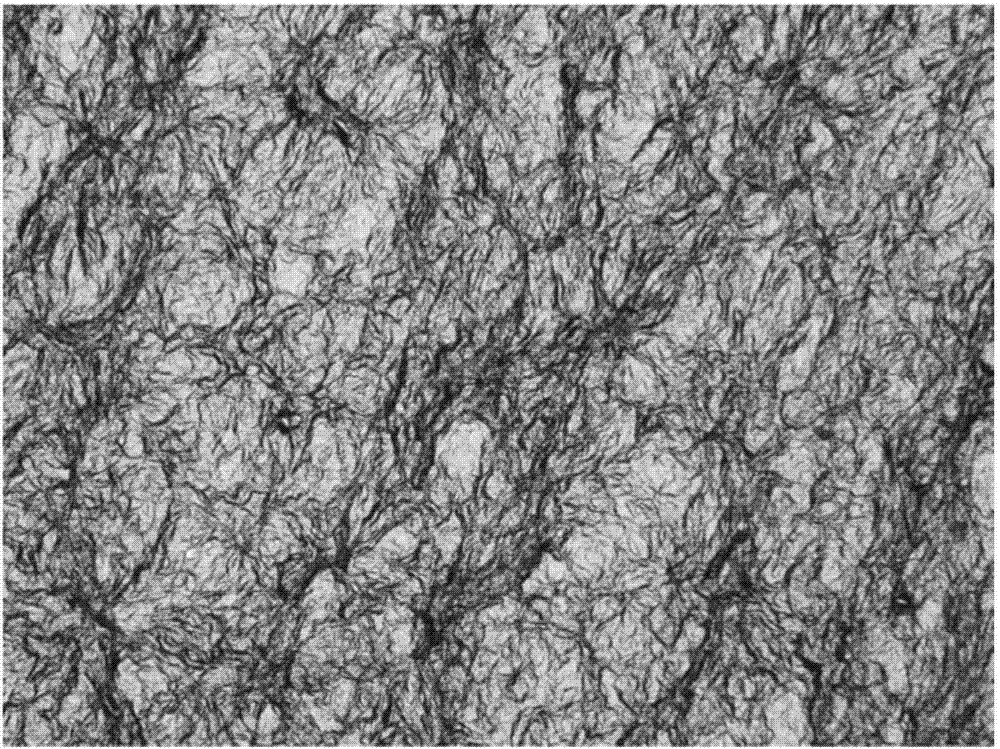

[0079] The preparation scheme of the miniature flexible and stretchable simple mechanical arm: fully mix the titanium nitride nanoparticles with the graphite oxide solution prepared above according to the mass ratio of 1:2, and ultrasonicate for 2 hours to obtain the first colloid evenly dispersed; place the glass slide on In a mixture of concentrated sulfuric acid and 30% hydrogen peroxide with a volume ratio of 7:3, treat at 80 degrees Celsius for 1 hour, and then rinse with deionized water. The first colloid was coated on the glass slide after the hydrophilic treatment, and baked on a heating plate at 50 degrees Celsius for 10 minutes to obtain a photothermal layer. Then configure PDMS mixed glue as the second colloid. Specifically, mix A and B components of PDMS glue (Dow Corning DC184) purchased in the market evenly in proportion (weight ratio), and carry out 5~20 mmHg vacuum. After degassing for 10 minutes, the second colloid was spin-coated on the above-mentioned photot...

Embodiment 2

[0081] The design scheme of the intelligent light control switch: fully mix the graphene with the above-mentioned prepared graphite oxide solution according to the mass ratio of 1:1, and ultrasonicate for 2 hours to obtain the first colloid evenly dispersed; the slide glass is placed in a volume ratio of 7: 3 in a mixture of concentrated sulfuric acid and 30% hydrogen peroxide, treated at 80°C for 1 hour, and then rinsed with deionized water. The above-mentioned first colloid was coated on the glass slide after hydrophilic treatment, and baked on a heating plate at 50 degrees Celsius for 10 minutes to obtain a photothermal layer. Then configure the PVP colloid as the second colloid, specifically dissolving the commercially purchased PVP in absolute ethanol and ultrasonicating for 2 hours to obtain a uniformly dispersed colloidal solution, and then spin-coat the second colloid on the above-mentioned substrate coated with the photothermal layer , and the rotational speed of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com