Fuel battery membrane electrode and preparation method thereof

A fuel cell membrane and electrode technology, used in fuel cells, battery electrodes, fuel cell components, etc., can solve the problems of high resistivity, unfavorable processing, small specific surface area, etc., achieve good mechanical strength and toughness, and improve the reaction. The effect of activity and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

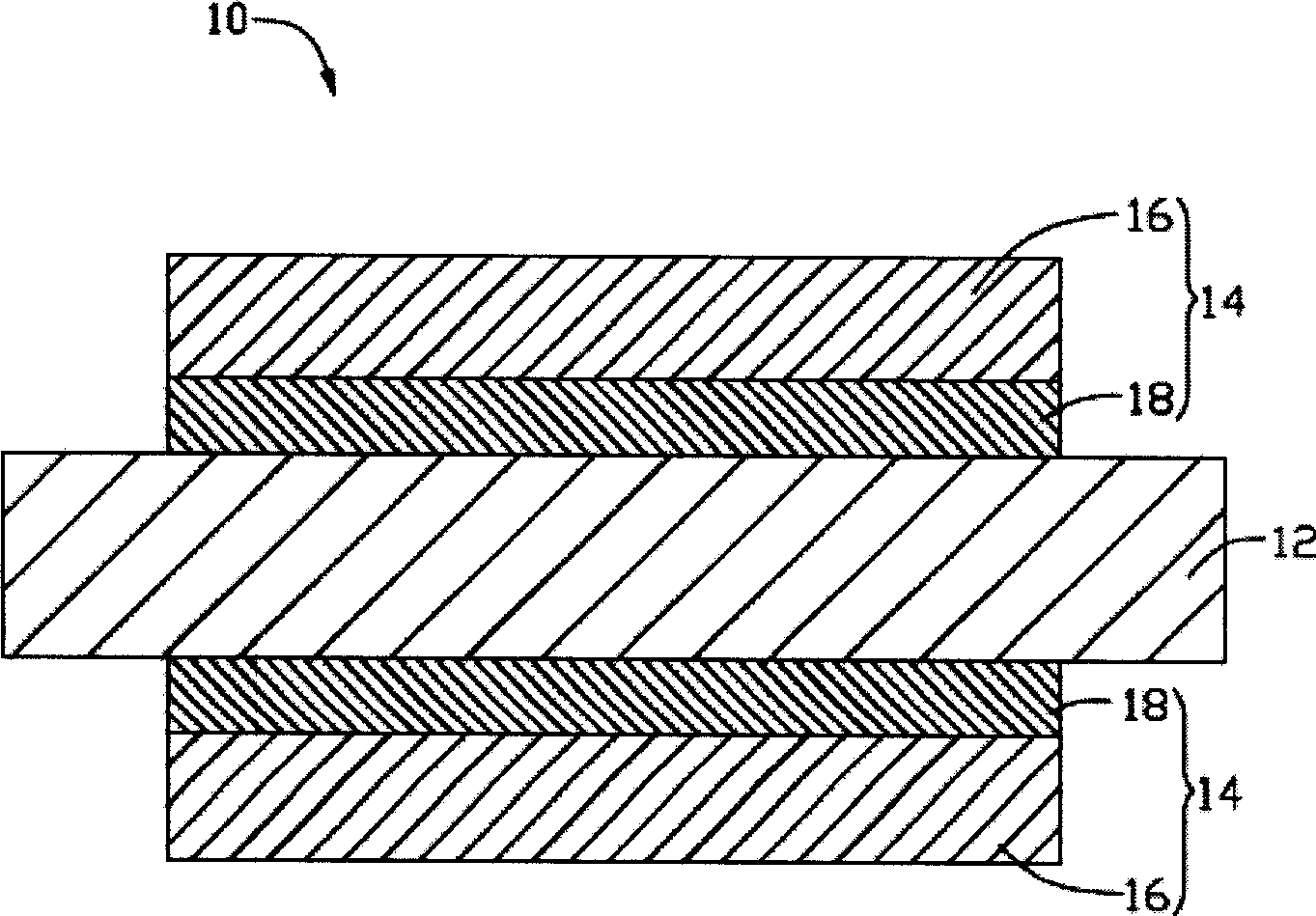

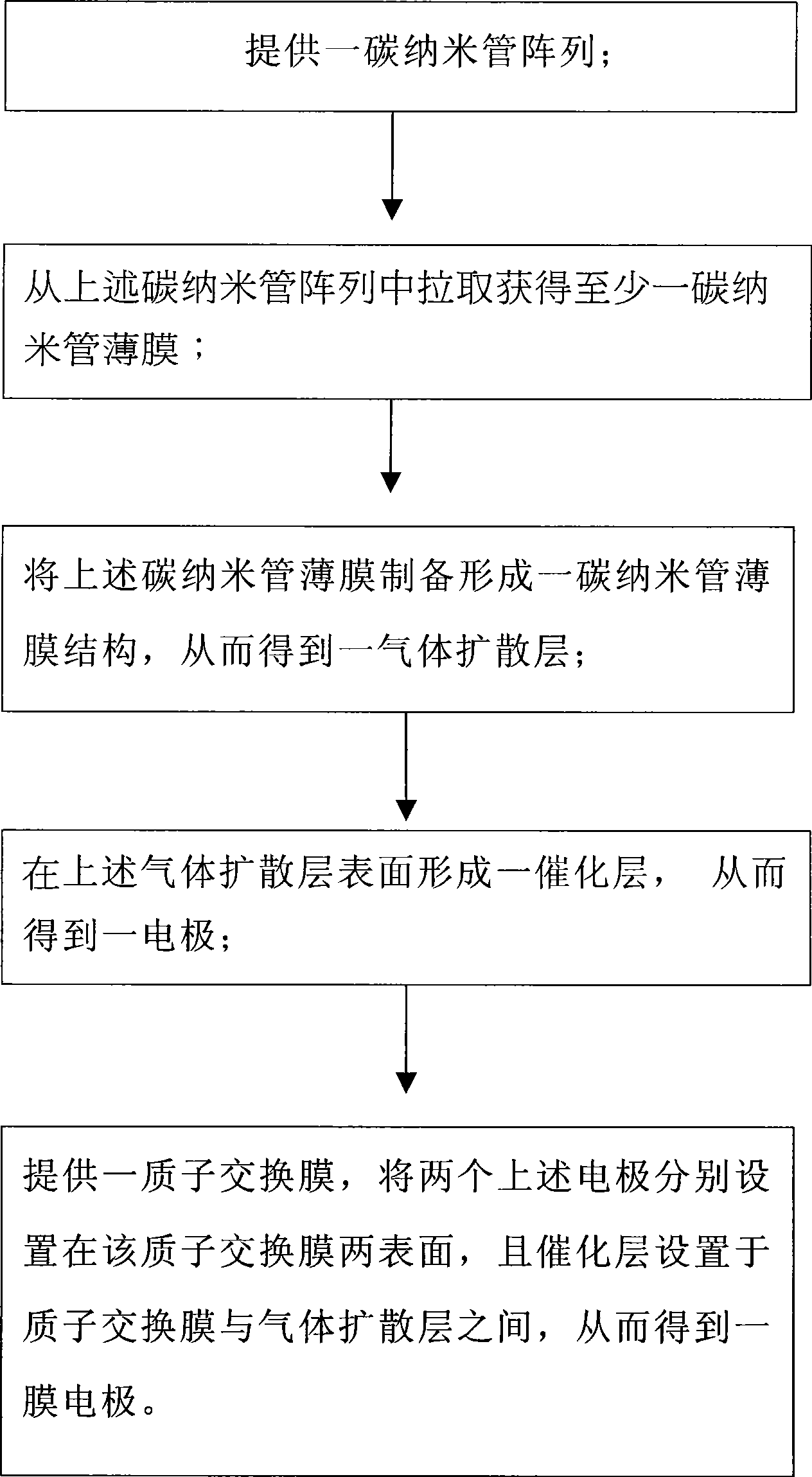

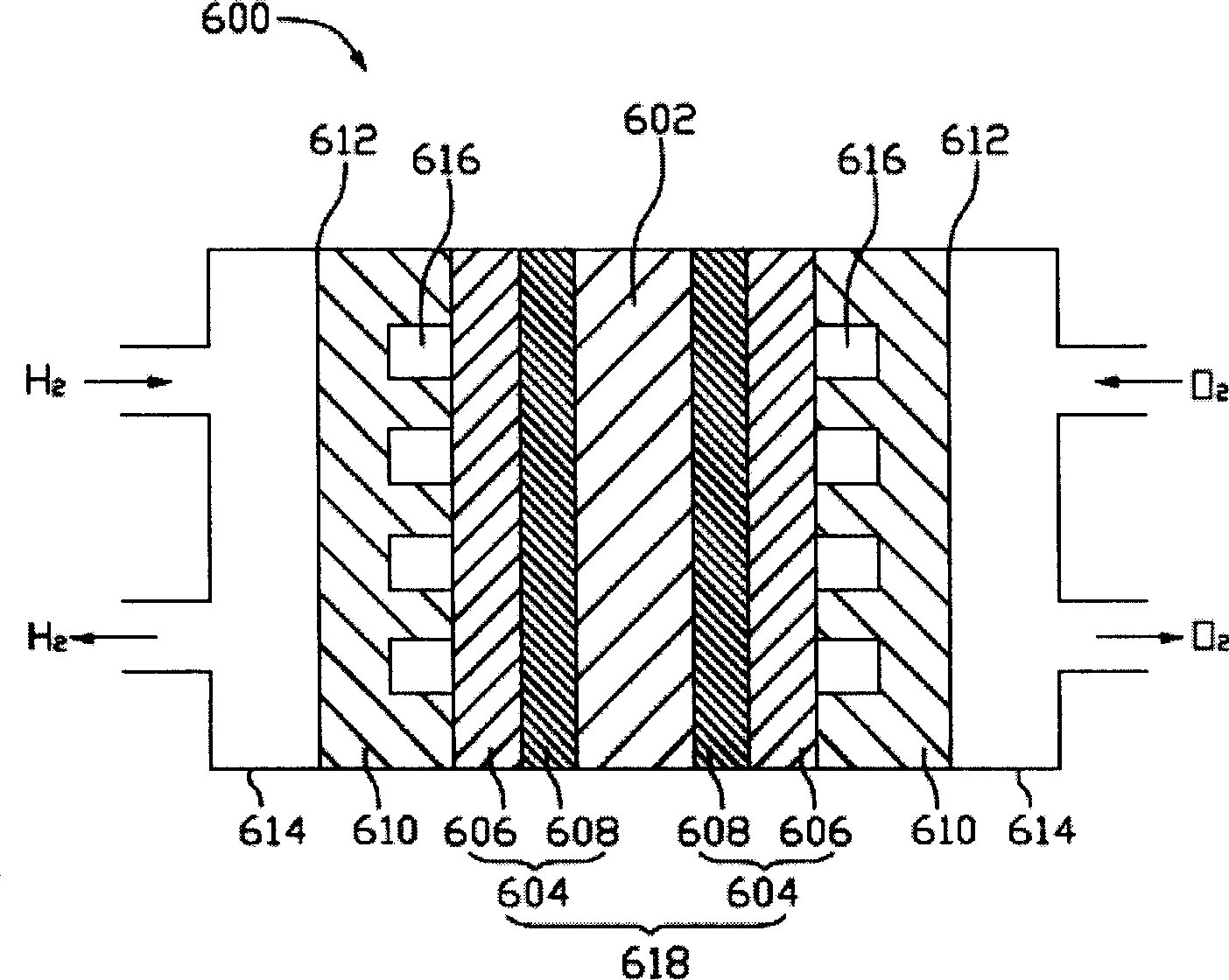

[0019] see figure 2 The embodiment of the technical solution further provides a method for preparing a fuel cell membrane electrode 10, which specifically includes the following steps:

[0020] Step 1: providing a carbon nanotube array.

[0021]In this embodiment, the carbon nanotube array is a super-arranged carbon nanotube array, and the preparation method of the super-arranged carbon nanotube array adopts a chemical vapor deposition method, and the specific steps include: providing a flat substrate, the substrate Can select P-type or N-type silicon substrate, or select the silicon substrate that has formed oxide layer for selection, present embodiment preferably adopts the silicon substrate of 4 inches; Form a catalyst layer uniformly on the substrate surface, this catalyst layer material can be selected iron (Fe ), cobalt (Co), nickel (Ni) or an alloy of any combination thereof; annealing the above-mentioned substrate formed with a catalyst layer in air at 700-900° C. fo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com