Wire rod excellent in wire-drawing workability and method for producing same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

working examples

[0056] The invention is more specifically described hereinafter with reference to working examples. It is to be pointed out, however, that the invention be not limited in scope by the working examples described hereunder, and that various changes and modifications may be obviously made in the invention in light of teachings described hereinbefore and hereinafter without departing from the spirit and scope thereof.

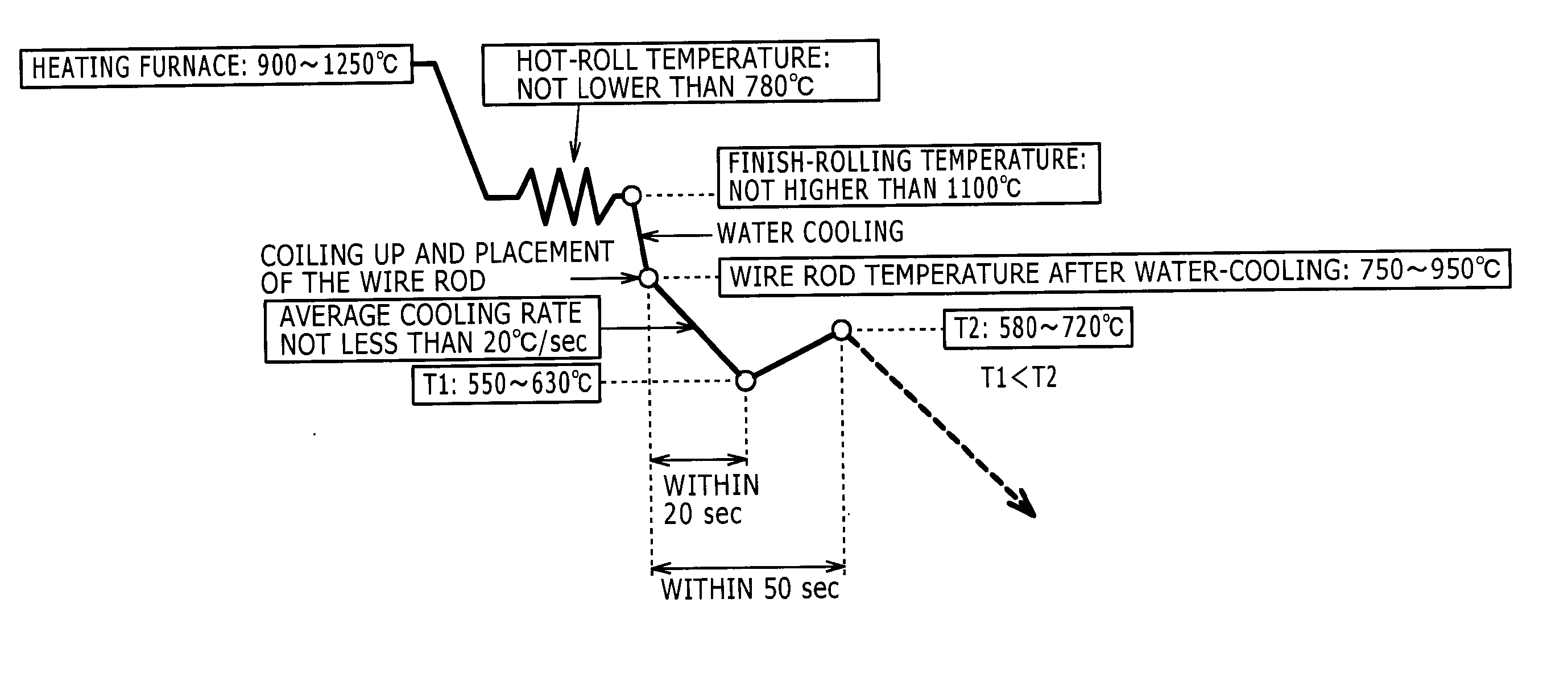

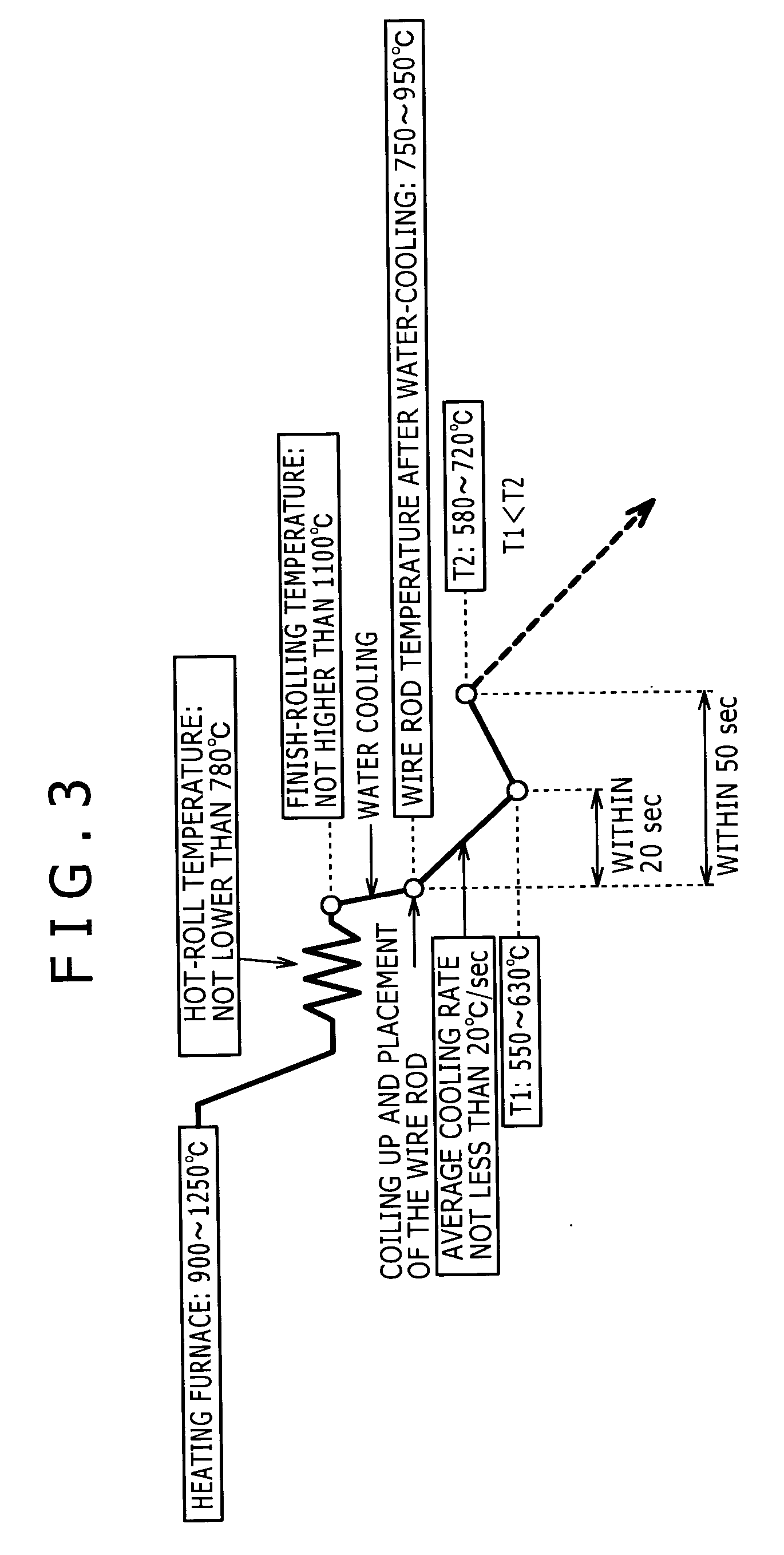

1. Production of Wire Rods

[0057] Hot rolled wire rods Nos. 1 to 29, each 5.5 mm in diameter, were produced under various conditions shown in Table 2, with the use of steel products S1 to S16, having chemical compositions shown in Table 1, respectively. More specifically, the steel products each were heated to a range of 978 to 1205° C. in a heating furnace to be hot rolled at a rolling temperature not lower than 807° C., and to be finish-rolled at a temperature not higher than 1068° C., thereby being formed into the respective wire rods. The wire rods each were water-coo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

| Temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com