Temperature synchronizing system and method used for metallurgic performance measuring device

A technology of synchronization system and measuring device, applied in the field of metallurgy, can solve the problems of uneven temperature of heated samples, unsynchronized furnace temperature changes, and uneven heat dissipation of the environment, so as to ensure uniformity and repeatability, improve efficiency, and improve The effect of uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

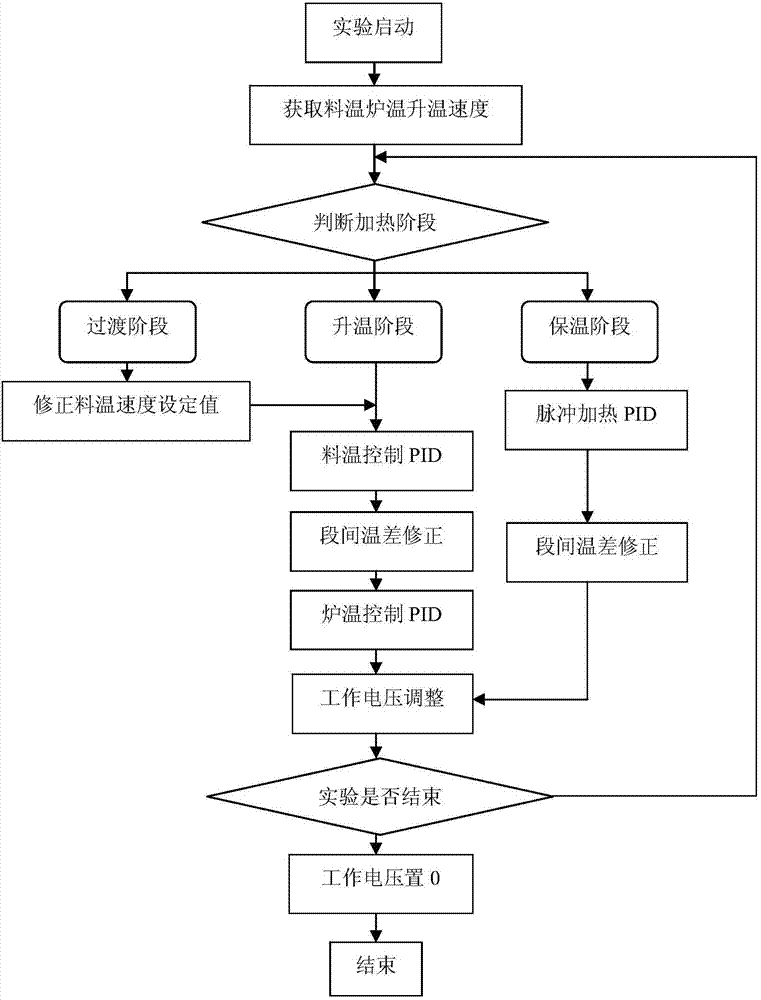

[0043] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

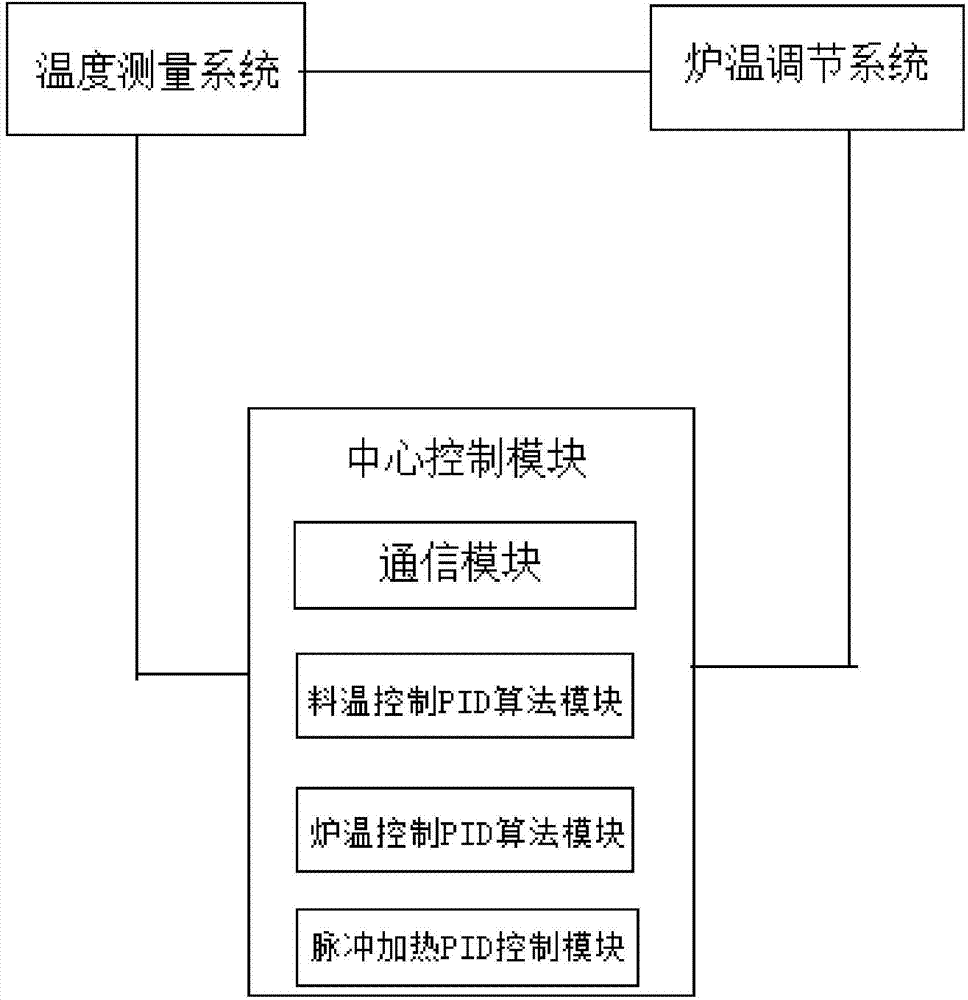

[0044] The metallurgical measurement device of the present invention is configured with a computer and a professional instrument control cabinet (including four thermocouple temperature measurement and display modules, three smart meters, and three thyristor rectifiers); wherein the three thermocouples are respectively arranged in Near the furnace wall of the three heating sections of the metallurgical performance measuring device, it is used to measure the furnace temperature; a thermocouple is arranged in the middle of the furnace containing the tested sample to measure the temperature of the sample; three thyristor rectifiers are respectively connected to the three The resistance wires of each heating section are connected to their respective smart meters to adjust the heating power of each section. The temperature data measured by the four thermocoup...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com