Friction welding process heat flow microstructure multi-physical field numerical calculation method

A microstructure, multi-physics technology, applied in computing, manufacturing computing systems, computer-aided design, etc., can solve the problems of low conformity, low efficiency and precision of friction welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

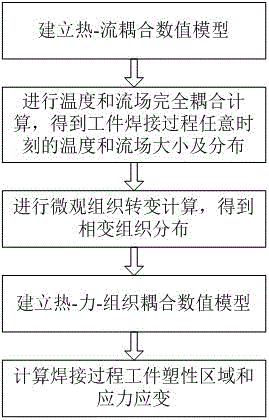

[0047] Such as figure 1 As shown, the multi-physics numerical calculation method of the thermal flow microstructure of the friction welding process includes the following steps in sequence: Step 1, establishing a heat-fluid coupling numerical model; Step 2, performing a fully coupled calculation of temperature and flow field, and obtaining The size and distribution of temperature and flow field at any time in the process; step 3, calculate the microstructure transformation, and obtain the distribution of phase transition structure; step 4, establish a thermal-mechanical-structure coupling numerical model; step 5, calculate the plastic area and stress strain.

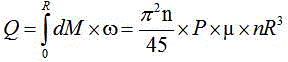

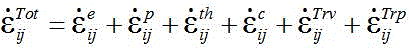

[0048] The Johndon-Cook model is used to describe the friction welding material when the heat-flow fully coupled numerical model and the heat-mechanical-structure coupled numerical model of this embodiment are established. The expression of the Johndon-Cook model is:

[0049] Among them, A is the yield strength of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com