Multiphysics Numerical Calculation Method of Thermal Flow Microstructure in Friction Welding Process

A technology of microstructure and numerical calculation, applied in the direction of calculation, manufacturing calculation system, computer aided design, etc., can solve the problems of low matching degree, low efficiency and precision of friction welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

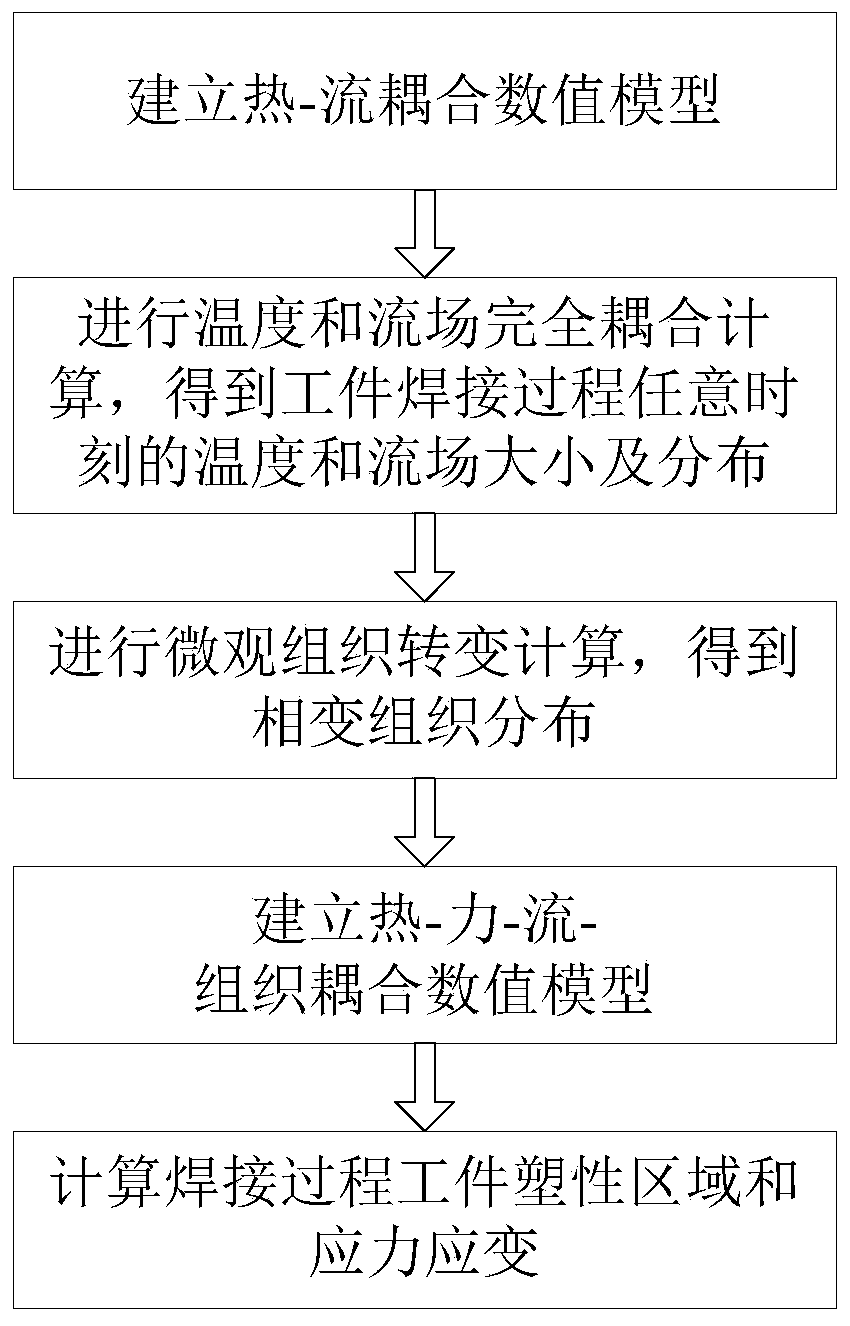

[0049] like figure 1 As shown, the multi-physics numerical calculation method of the thermal flow microstructure of the friction welding process includes the following steps in sequence: Step 1, establishing a heat-fluid coupling numerical model; Step 2, performing a fully coupled calculation of temperature and flow field, and obtaining The size and distribution of the temperature and flow field at any time in the process; step 3, calculate the microstructure transformation, and obtain the distribution of the phase transition structure; step 4, establish a heat-force-flow-structure coupling numerical model; step 5, calculate the plasticity of the workpiece during the welding process Area and stress-strain.

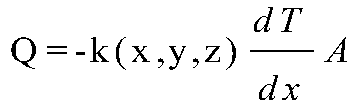

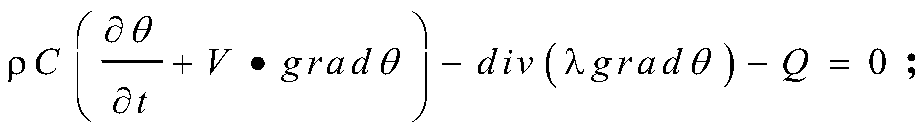

[0050] The Johndon-Cook model is used to describe the friction welding material when the heat-flow fully coupled numerical model and the heat-force-flow-structure coupled numerical model of this embodiment are established. The expression of the Johndon-Cook model is:

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com