Optical fiber image inverter rotary torsion processing technology

A processing technology and image inverter technology, which is applied in the field of optical fiber image inverter rotation and torsion processing, can solve problems such as poor quality of optical fiber image inverters, improve the pass rate and quality rate, solve distortion, and reduce uniformity requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

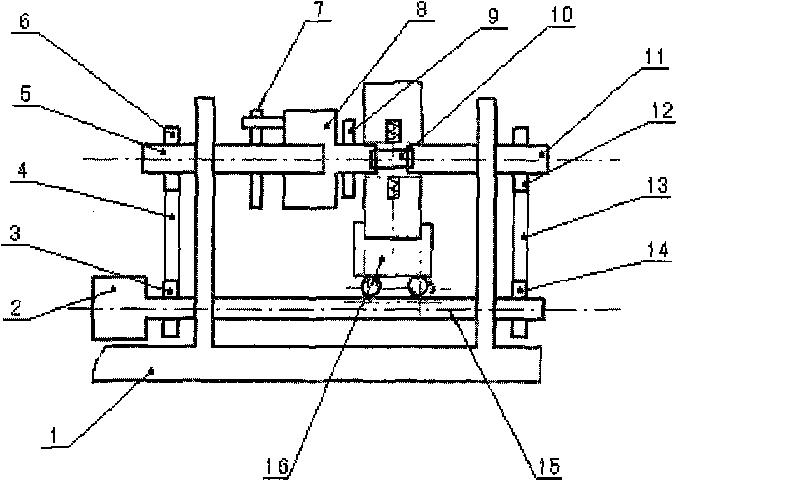

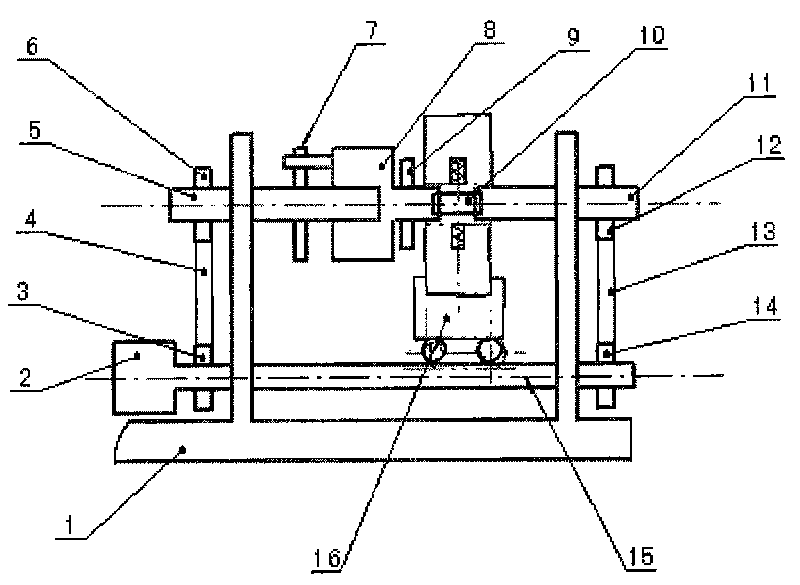

[0014] Such as figure 1 As shown, the structure of the torsion machine includes a base and a support 1. The base is provided with a motor 2 and a synchronous shaft 15 that is activated by the motor. The synchronous shaft 15 is meshed with synchronous transmission teeth 3, 4, 6; synchronous transmission teeth 14, 13 , 12, left shaft 5 and right shaft 11 are respectively pierced on the bracket, synchronous transmission teeth 3, 4, 6 drive left shaft 5, synchronous transmission teeth 14, 13, 12 drive right shaft 11, and left shaft 5 is provided with synchronization The mechanism 7, the torsion structure 8 and the resistance mechanism 9, the torsion mechanism 8 and the right shaft 11 are opposed to each other (the workpiece is connected between them). A heating furnace 16 is also provided between the left shaft 5 and the right shaft 11.

[0015] The left shaft 5 and the right shaft 11 can rotate synchronously under the driving of the synchronization shaft 15, and the left shaft 5 ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com