Horizontal moving steel band recoiling device

A translational, steel-belt technology, applied in the direction of coiling strips, transportation and packaging, thin material handling, etc., can solve the problems of easy-to-damage steel belts, low degree of automation, and high labor intensity of workers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

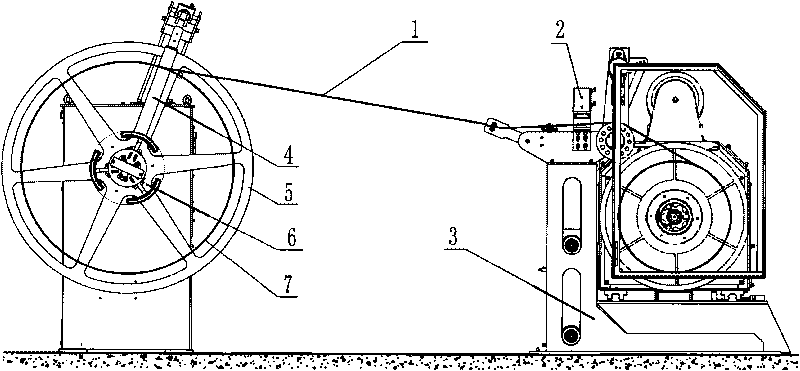

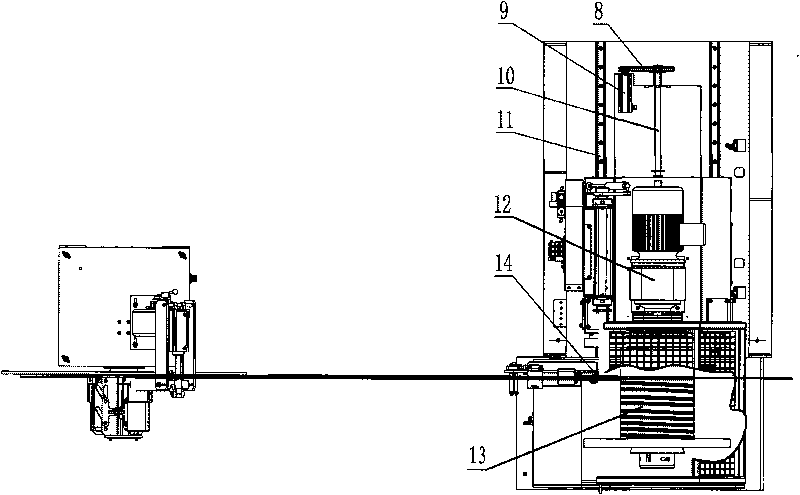

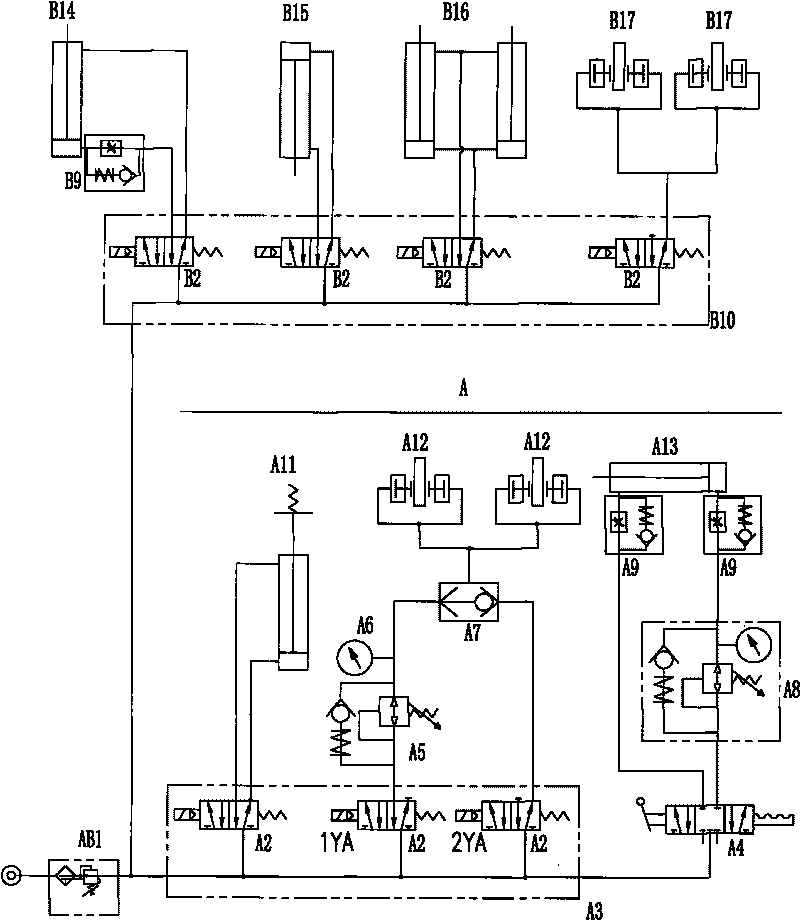

[0024] With reference to the accompanying drawings, the translational steel strip recoiling device of the present invention is described in detail as follows:

[0025] The device is composed of two parts: a tape unwinding device and a tape take-up device. Belt reel 7, synchronous belt 8, servo motor 9, ball screw pair 10, linear guide pair 11, variable speed reducer 12, I-shaped wheel 13, encoder 14 for meter counting figure 1 , figure 2 The connection relationship shown in the structure is composed, the tape unwinding device and the tape take-up device are respectively arranged on the left and right sides, the tape unwinding device is pulled by the tape-winding device, and the take-up I-shaped wheel 13 reciprocates and slides back and forth so that the steel belt 1 is evenly wound on the take-up I-shaped On wheel 13. The take-up translation device passes through the set servo motor 9, the synchronous belt 8 transmission belt ball screw pair 10, the screw nut is connected ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com