Novel rectangular flexible four-jaw chuck

A four-jaw chuck, rectangular technology, applied in chucks, vises, workpiece clamping devices, etc., can solve the problems of the structure of the flexible four-jaw chuck not being compact enough, reducing the usable height of the Z-axis of the machine tool, and the overall height. , to achieve the effect of increasing the usable height, strong practicability and reducing the overall height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

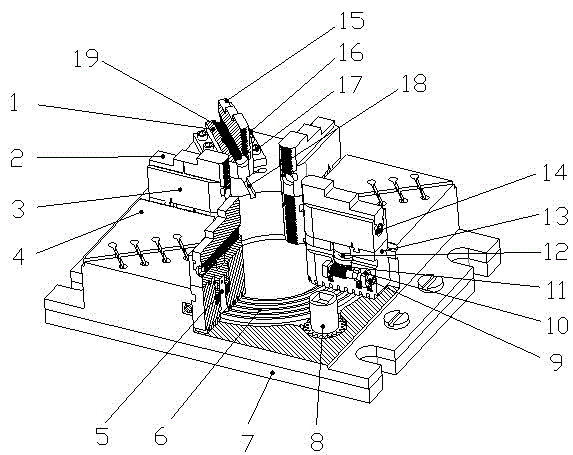

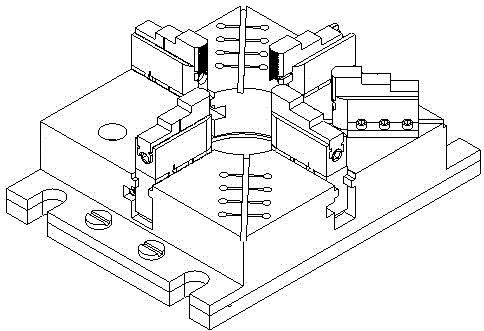

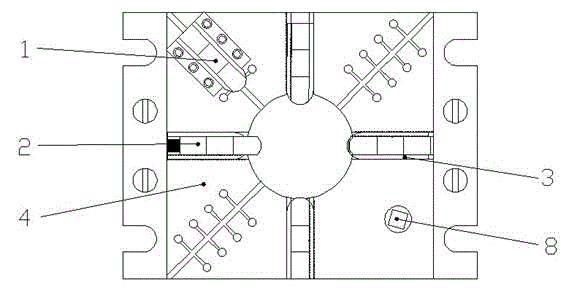

[0022] The specific implementation manners of the present invention will be described in further detail below in conjunction with the accompanying drawings.

[0023] Such as Figures 1 to 3 As shown, a new type of rectangular flexible four-jaw chuck includes a rectangular chuck body 4 fixedly arranged on a base 7, four linkages arranged on the chuck body 4 at an angle of 90 degrees and driven by a wire reel 6. Claw 13, four movably arranged on the interlocking claw 13 turn to the middle block 3, four screw rods 14, four sliding claws 12, the sliding claws 12 cooperate with the screw mandrel 14, and the screw mandrel 14 In the arc groove at the upper end of the steering middle block 3, the stop ring fixed to the steering middle block 3 limits the axial movement of the screw 14, and also includes four worms 9, four worm wheels 11 with through holes, and four inverted T-shaped Countersunk head polished rod 5, the middle part of the linkage claw 13 is provided with a stepped hole...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com