Novel tuned particle mass damper

A technology of tuning mass damping and particle dampers, which is applied to bridge parts, building components, bridges, etc., can solve the problems of restricting particle rolling or sliding, friction, collision, etc., and achieves ease of use and enhanced energy consumption and vibration reduction effects Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

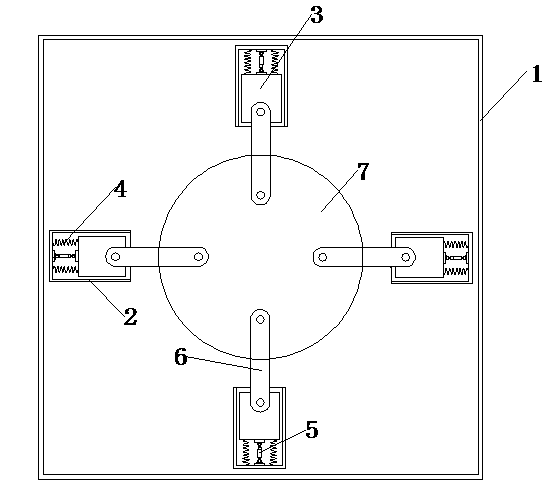

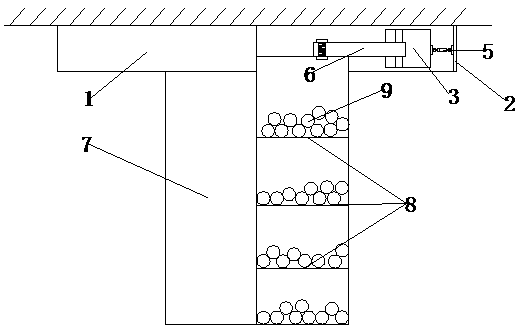

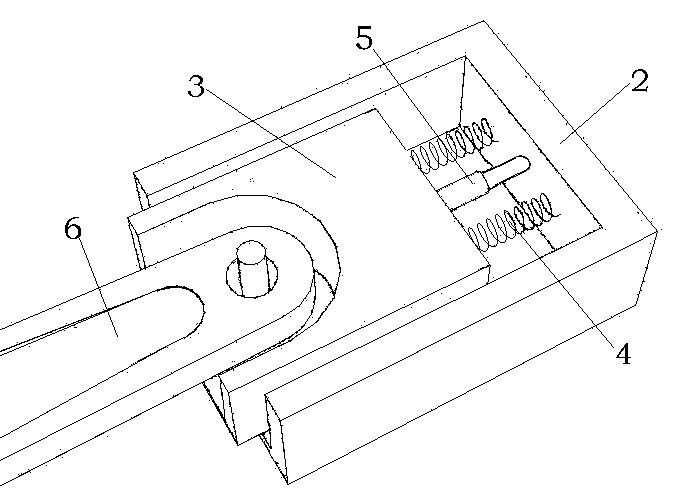

[0021] Embodiment 1: as Figure 1 to Figure 4 As shown, it is a new tuned particle damper of the present invention, including a damper fixing plate 1, a mass sliding cavity 2, a mass 3, a connecting spring 4, a viscous damper 5, a connecting rod 6, and a damper cavity 7 , a damper compartment plate 8 and multi-graded damping particles 9 . The mass 3 can slide in the mass sliding cavity 2 with low damping. The connecting spring 4, the viscous damper 5 are connected with the inner wall of the mass sliding chamber 2 and the outer side of the mass 3, the connecting rod 6 is connected with the inner side of the mass 3 and the damper cavity 7; the damper cavity 6 is a cylinder, vertical The direction contains more than two damper bulkheads 8, each damper bulkhead 8 is evenly placed with multi-graded damper particle groups 9; the movement of the damper cavity 7 in the plane is opposite to the motion of the basic structure, resulting in Contrary to the control force of the structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com