Metal sheath stripping device for rail transit cable

A metal sheath and traffic cable technology, which is applied in the direction of dismantling/armouring cable equipment, etc., can solve the problems of inability to strip a large length, easy to damage the cable core, and high labor intensity, so as to reduce labor intensity and improve stripping efficiency , Improve the effect of stripping efficiency and precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

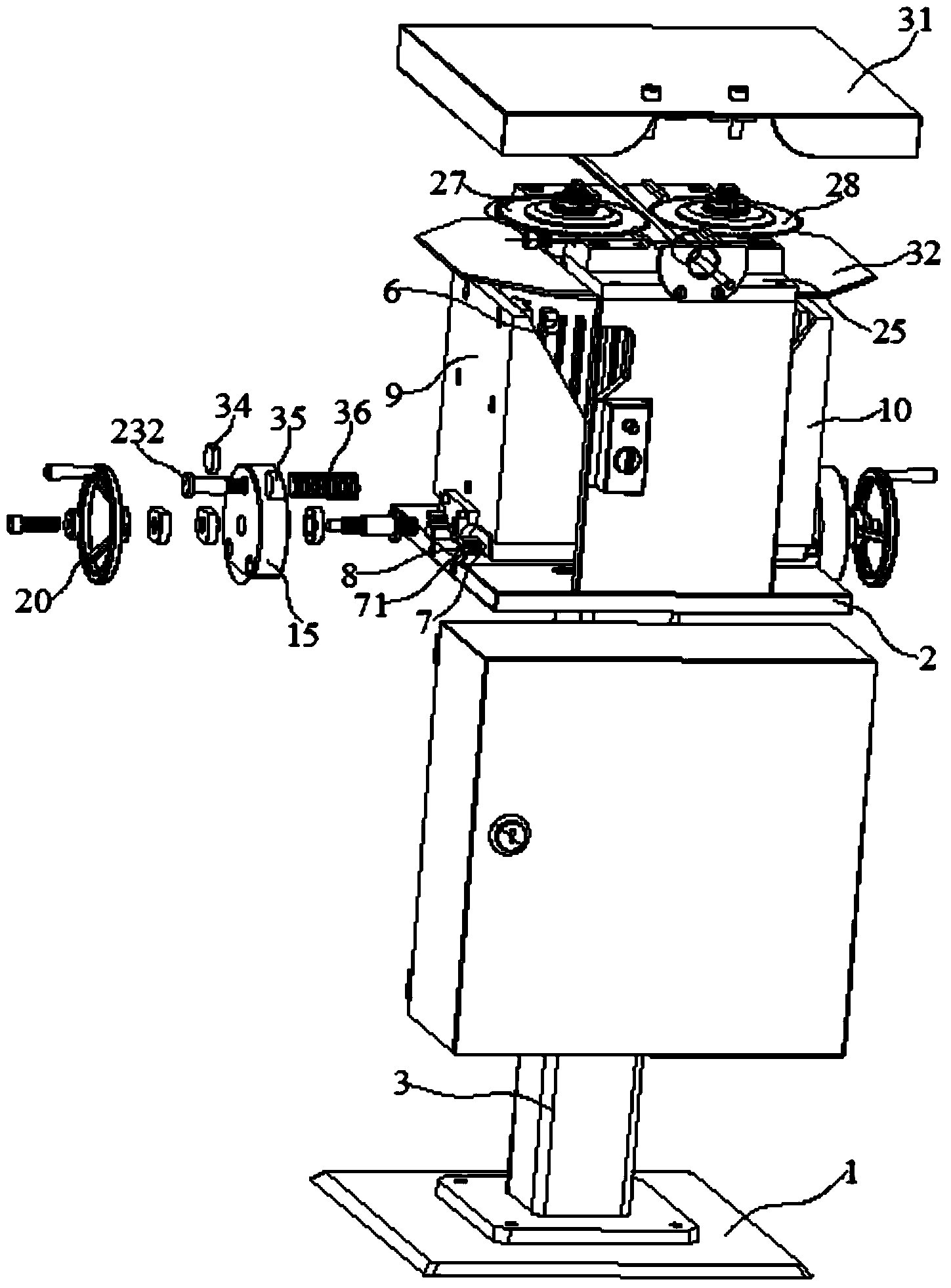

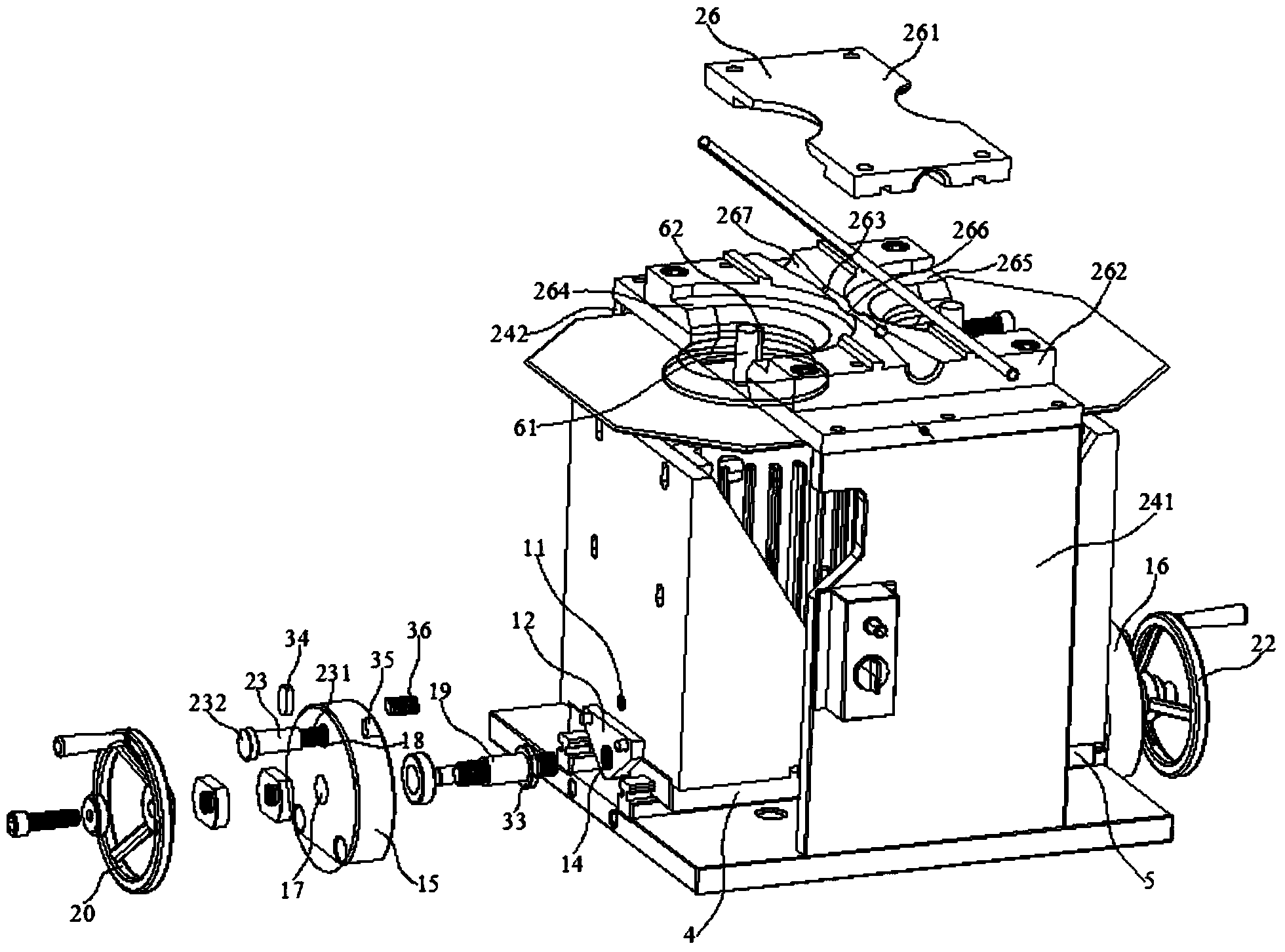

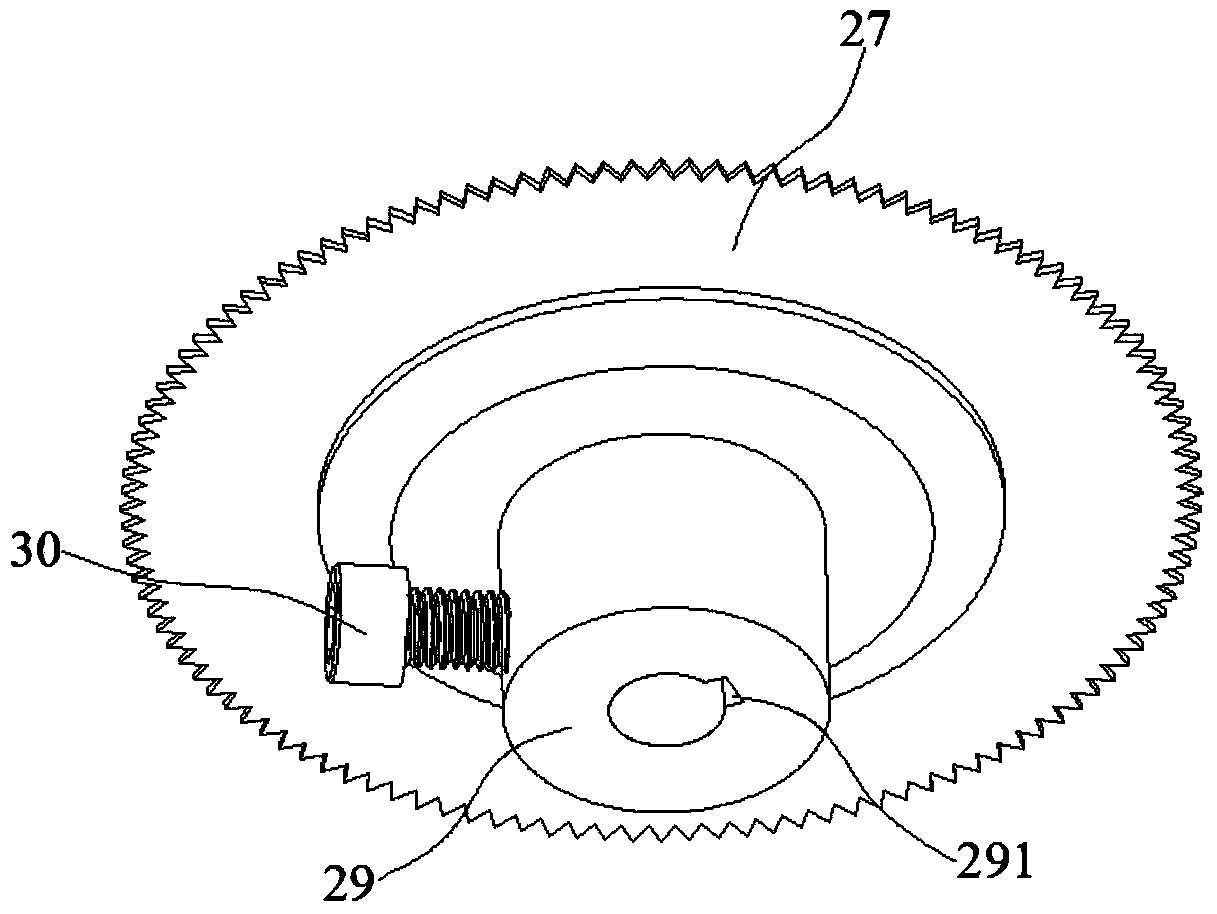

[0028] Embodiment: A metal sheath stripping device for rail transit cables, comprising: a base 1, a fixed base plate 2, a column 3 fixed between the base 1 and the fixed base plate 2, left and right motor brackets 4, 5 and 2 motors 6; one of the 2 motors 6 is installed on the left motor bracket 4, and the other is installed on the right motor bracket 5, and the respective lower surfaces of the left and right motor brackets 4 and 5 are fixed with 2 motors in parallel. a slider 7, two line rails 8 are arranged in parallel on the fixed base plate 2, and the line rails 8 are embedded in the grooves 71 of the respective sliders 7 of the left and right motor brackets 4 and 5 in turn; Left and right baffle plates 9,10 with adjusting screw holes 11 are respectively fixed on the respective outer sides of right motor support 4,5, and left and right baffle plates 9,10 with driving screw holes 14 are respectively fixed on the respective outer sides of the left and right baffle plates 9,10....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com