Automatic stripping mechanism

An automatic and material technology, applied in the direction of layered products, lamination auxiliary operation, lamination, etc., can solve the problems of low work efficiency, increase the labor intensity of operators, and low stripping speed, so as to improve work efficiency and reduce production The effect of cost and labor intensity of operators and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

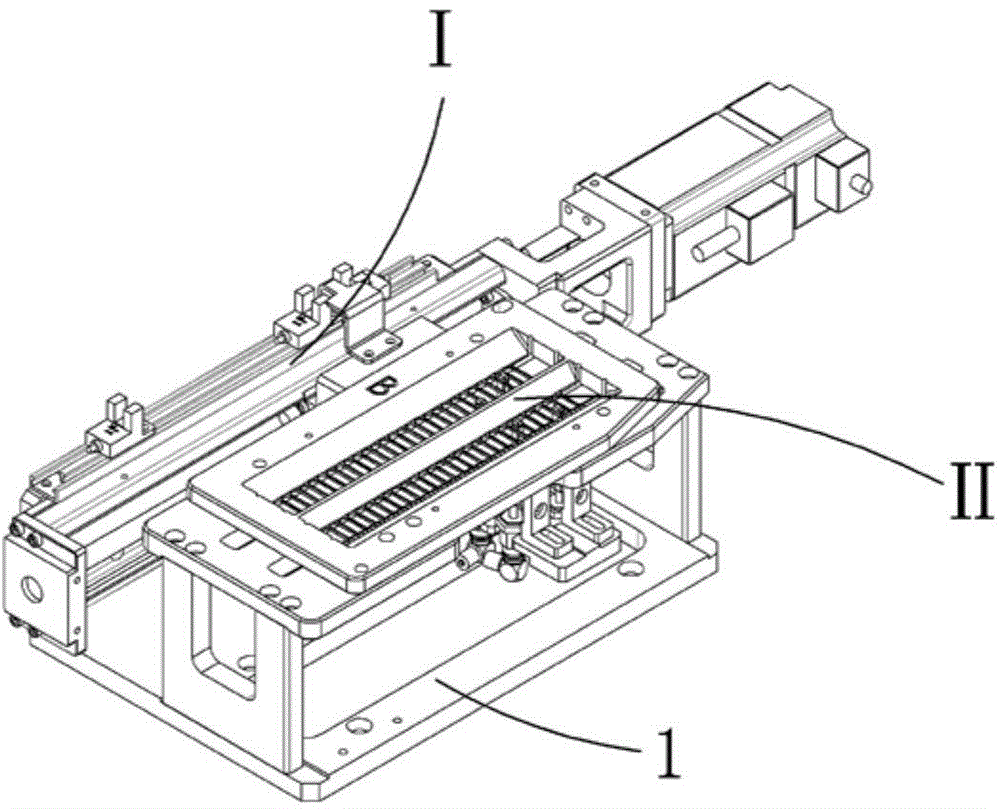

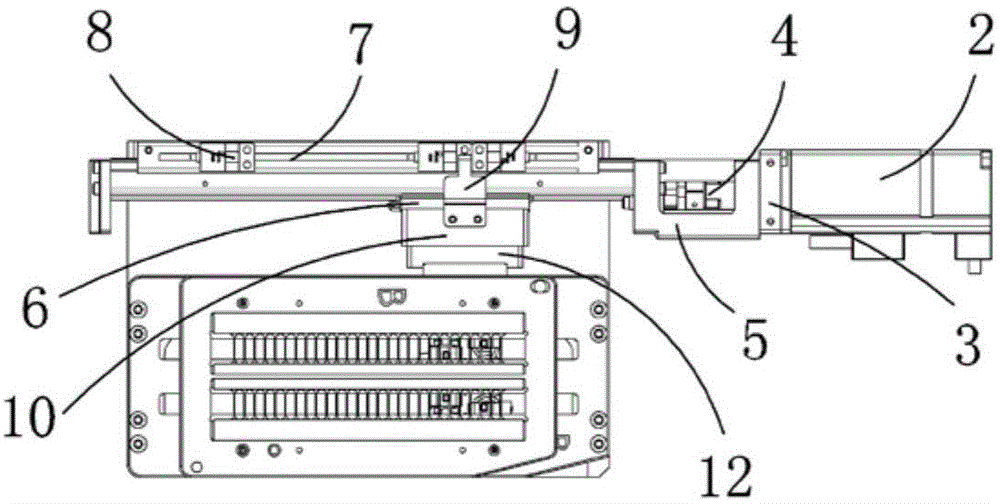

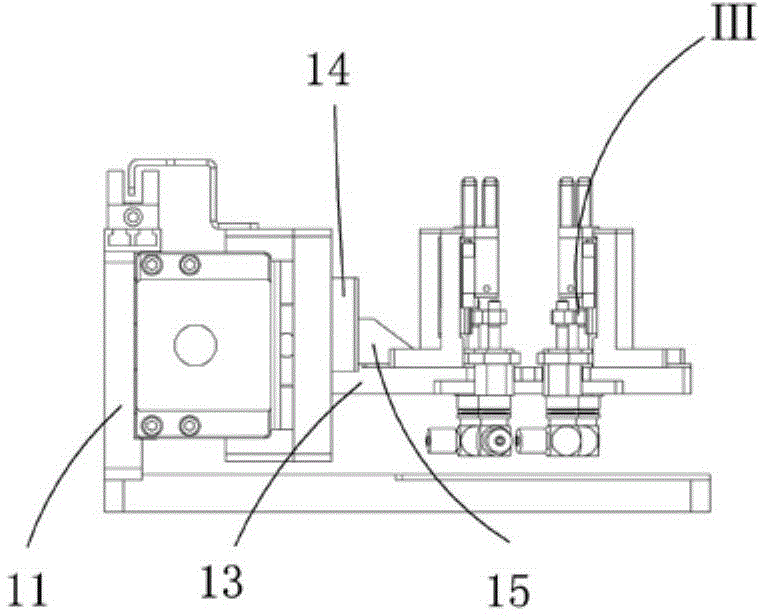

[0021] Examples, see attached Figure 1~5 , an automatic stripping mechanism, which includes a base plate 1, on which a material stripping mechanism I and a material placement mechanism II are installed on the bottom plate, and the material stripping mechanism includes a motor 2, a motor mounting plate 3, a coupling 4, a linear mold Group 5, linear module slider 6, mounting strip 7, photoelectric sensor 8, induction sheet 9, module connecting plate 10, module fixing plate 11, cylinder mounting plate 12, cylinder fixing plate 13, cylinder adjusting plate 14 and reinforcement Rib 15, the module fixing plate is vertically installed on the base plate, the linear module is fixed on the module fixing plate, the motor is installed on the motor mounting seat, and is connected with the linear module through a coupling; The installation strip is installed on the top of the module fixing plate, and three photoelectric sensors are installed on the installation strip, and the photoelectric...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com