A high-power current stripping tool and its application method

A high-power, high-current technology, applied in the installation of cables, cable installation devices, electrical components, etc., can solve the problems of difficult removal of the enameled wire paint layer, low stripping efficiency, and increased staff fatigue, so as to reduce work. Quantity, novel design concept, fast and accurate peeling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

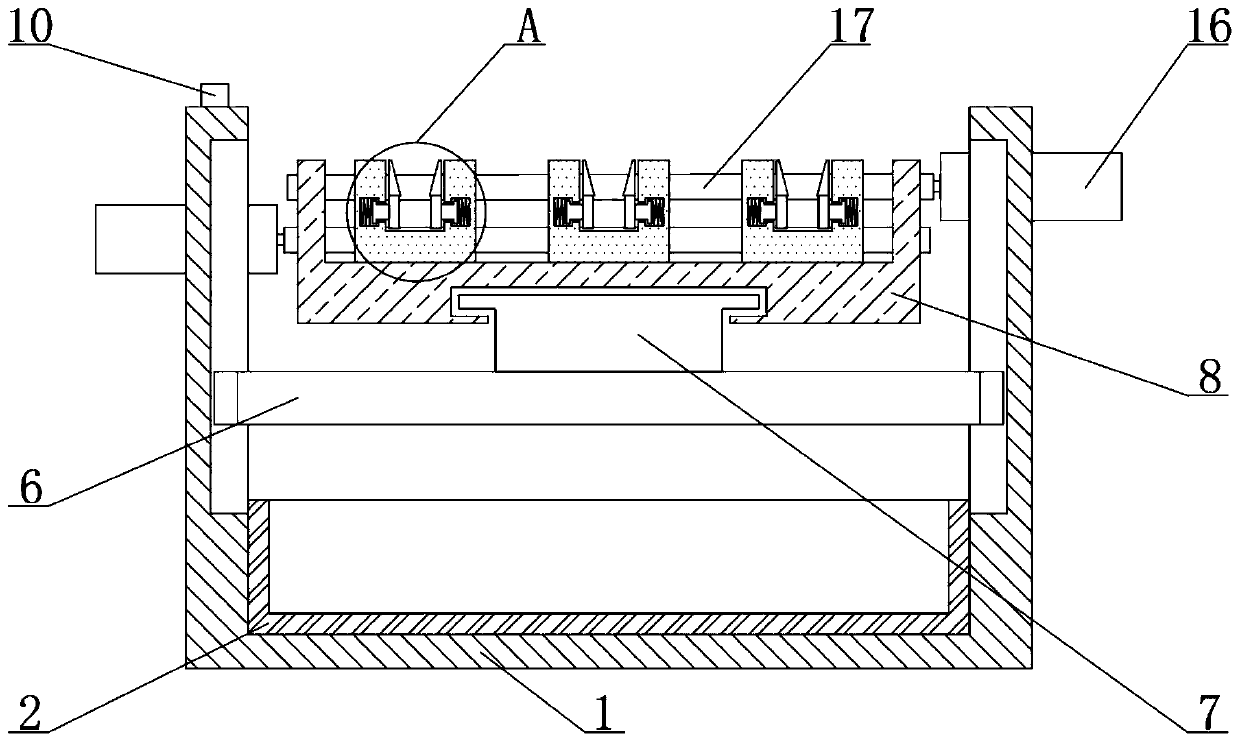

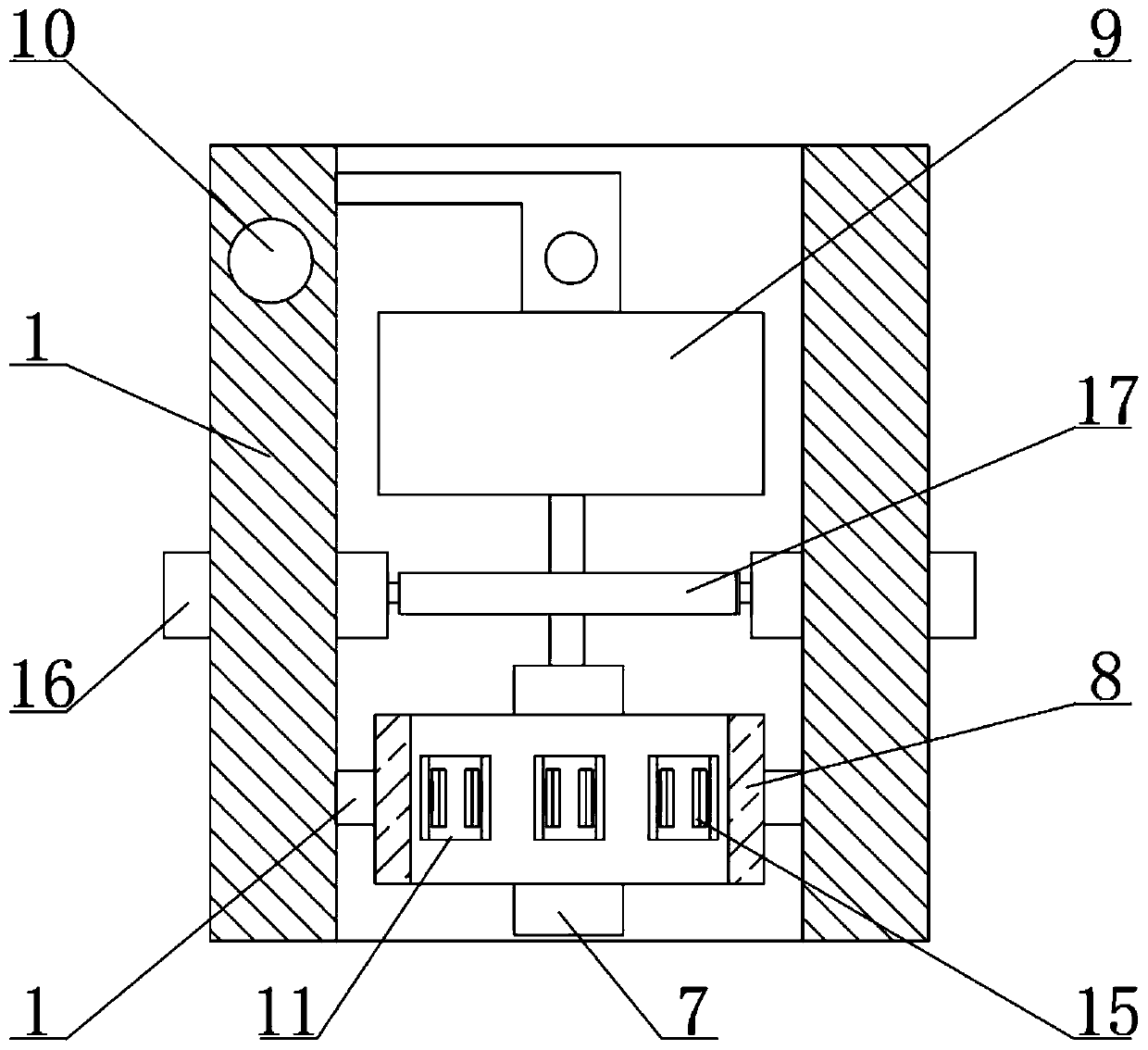

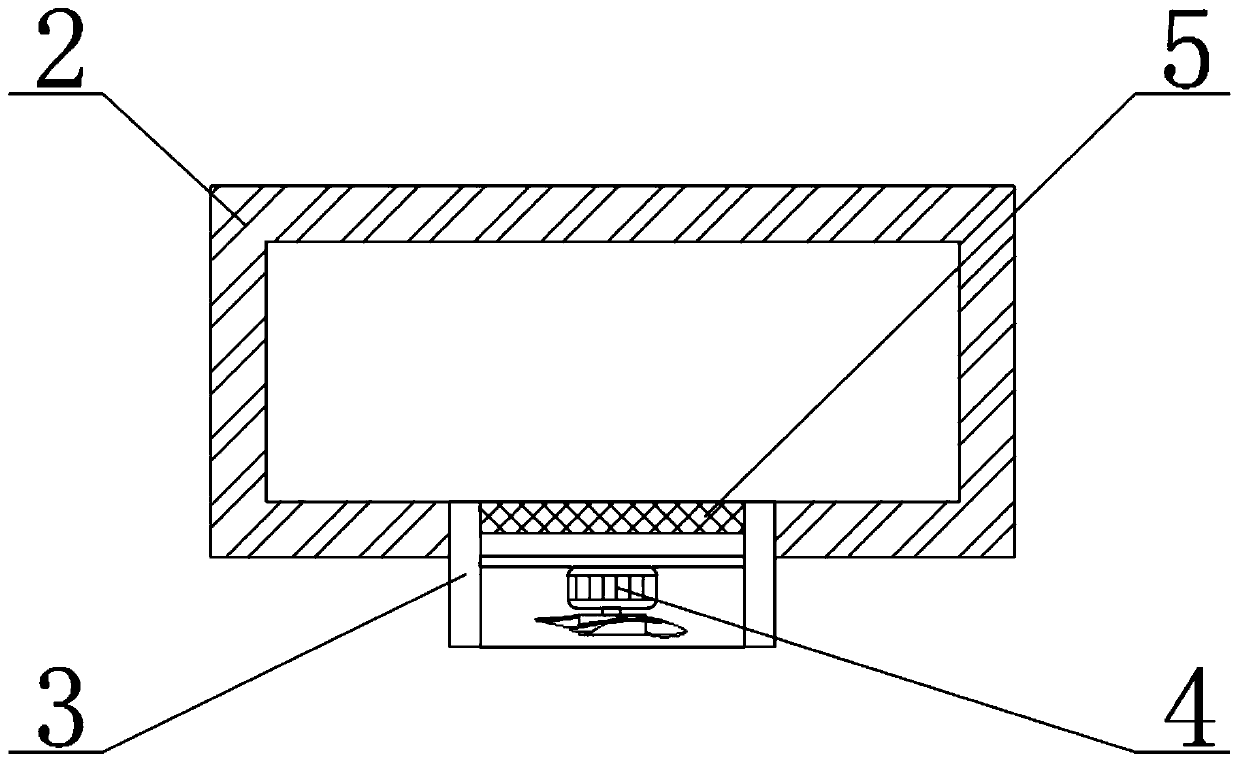

[0027] The specific embodiments of the present invention will be described below in conjunction with the drawings.

[0028] Such as figure 1 , figure 2 , image 3 with Figure 4 As shown, the high-power current stripping tooling of this embodiment includes a fixing frame 1 and a motor 16. A collection box 2 is slidably connected to the inner side of the bottom end of the fixing frame 1, and a wind box 3 is connected to the front end of the collection box 2. The fan 4 and the filter 5 are arranged front and rear, and the fan 4 is fixedly connected to the wind box 3 through a connecting rod, the filter 5 is fixedly connected to the wind box 3, the inner side of the fixing frame 1 is slidably connected with a sliding rod 6, and the top surface of the sliding rod 6 is fixedly connected with The first slider 7, the outer side of the first slider 7 is slidably connected to the limiter frame 8, the inner side of the fixed frame 1 is slidably connected to the peeling length positioning ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com