Device and method for calibrating plumb aligner

A collimator and sighting technology, applied in the field of collimator calibration, can solve the problems of inconvenient operation, insufficient system stability, deviation from the use state, etc., to achieve excellent calibration uncertainty, avoid unstable factors, and avoid optical The effect of poor parallelism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

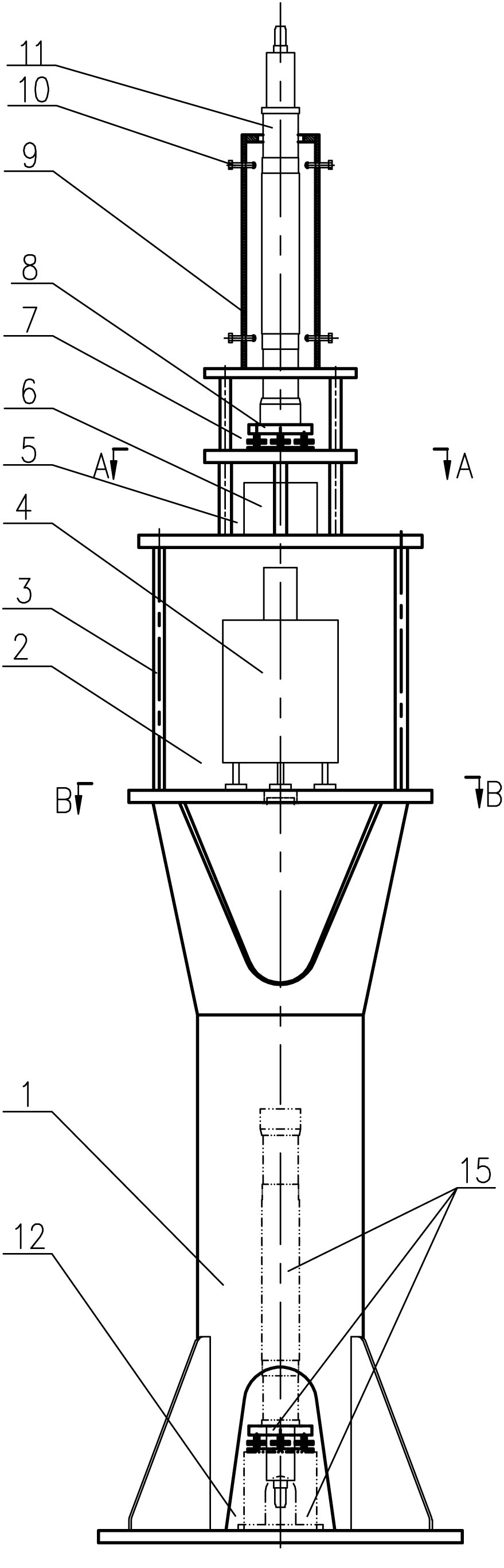

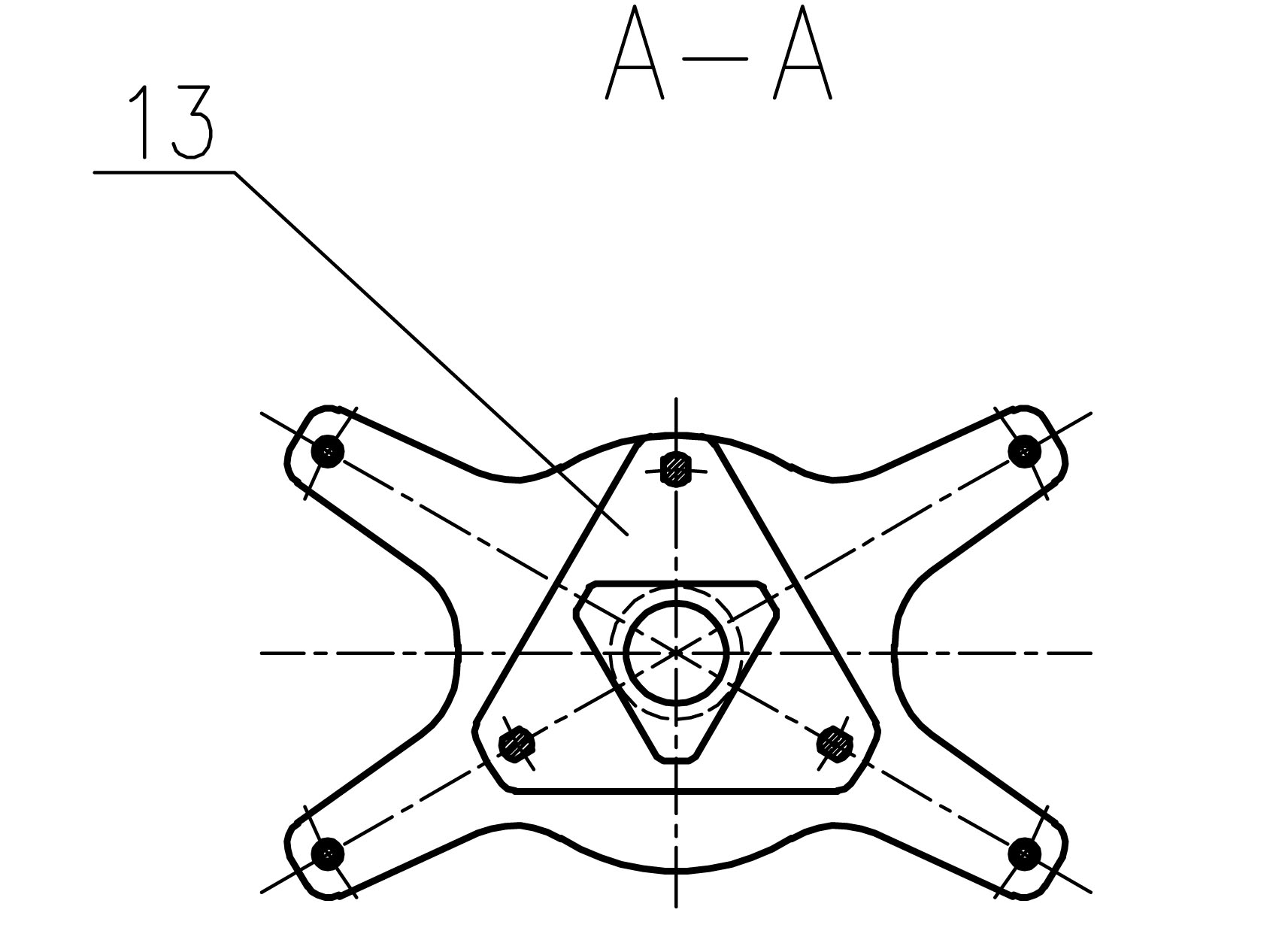

[0035] Such as figure 1 Among them, a device for calibrating the plummet, the vertical column 1 is provided with a vertical collimator placement cabin and an operating platform 2, the plummet placement cabin and the operating platform 2 are connected to the laser mirror cabin 5 through the pillar 3, and the laser mirror cabin 5 is connected with the fine adjustment cabin 7 through a pillar, and the fine adjustment cabin 7 is provided with a coarse adjustment head 9; the column 1, the plummet placement cabin and the operating platform 2, the laser mirror cabin 5 and the fine adjustment cabin 7 are all equipped with Through holes through which light passes;

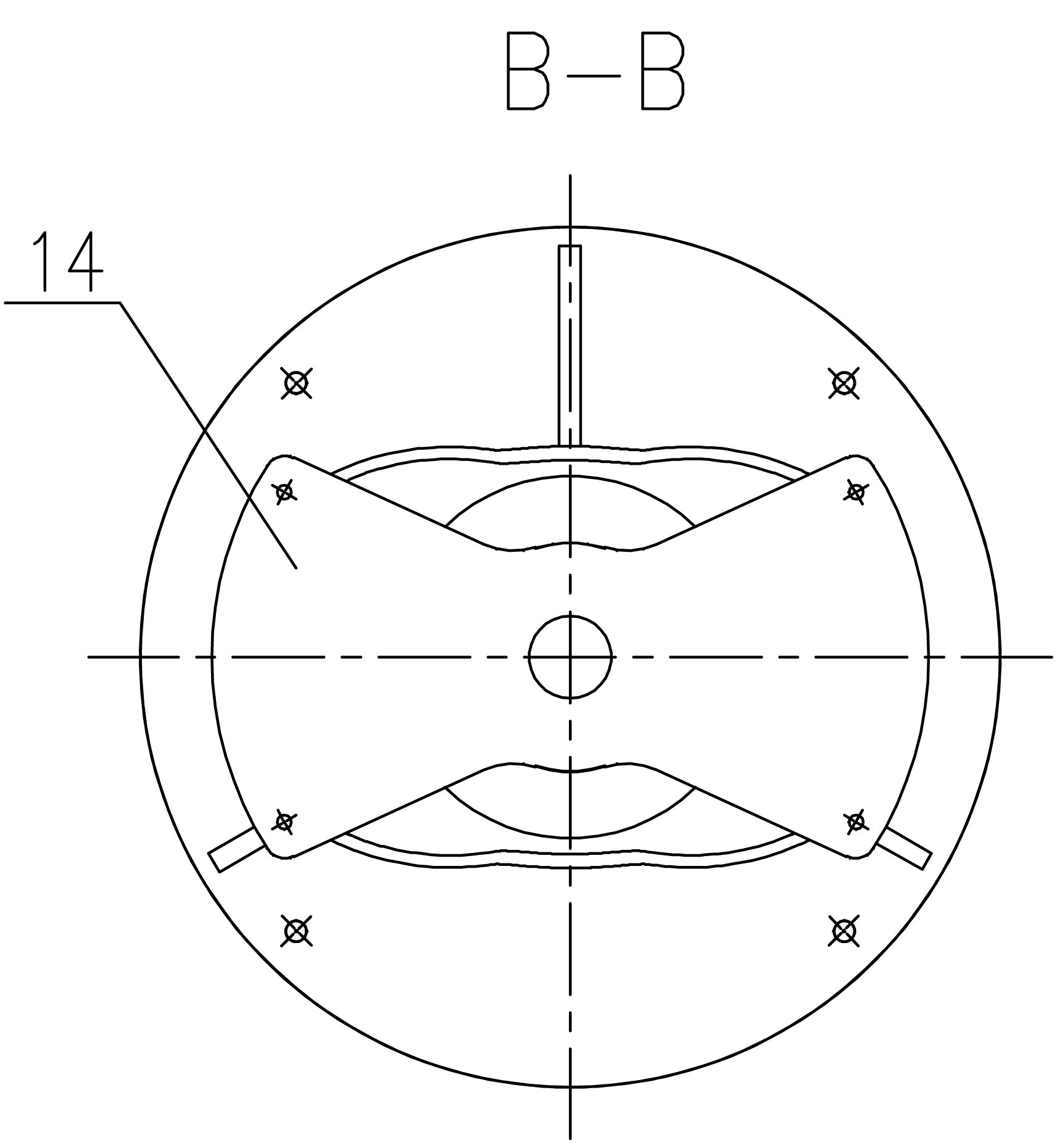

[0036] The lower end of the column 1 is provided with a ground point aiming standard cabin 12 and a space for setting the nadir aiming standard is reserved. The horn structure is formed between the column 1, the plummet cabin and the operating platform 2, and symmetrical double-sided parabolic openings are arranged on both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com