Precise separation device and method for down and hair fibers of animals

A fluff fiber and separation device technology, which is applied in the field of spinning, can solve the problems of weak striking force, large fiber damage, less fluff, etc., and achieves the effect of reducing the number of carding and low-damage carding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

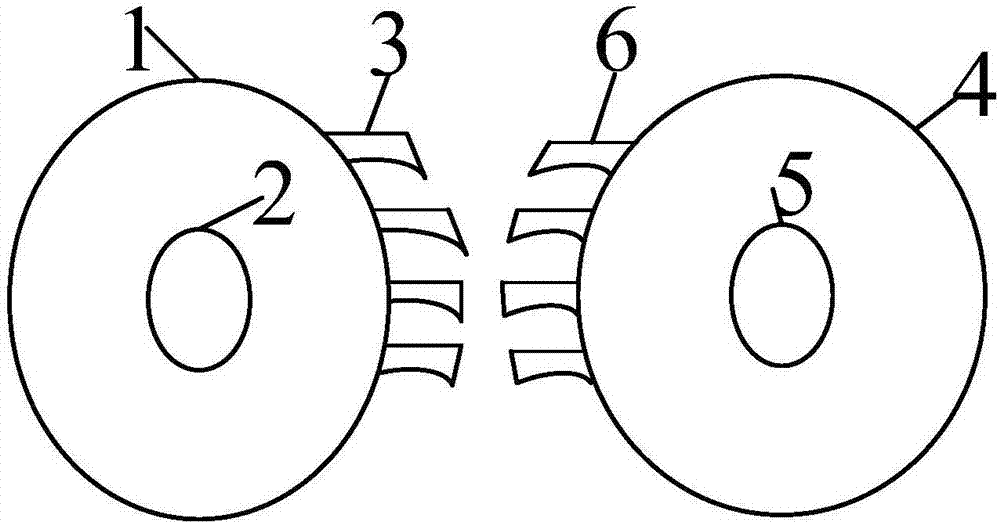

[0018] Depend on figure 1 As shown, a device for precisely separating animal hair fibers includes a pair of roller pairs with equal diameters. The pair of rollers includes raw velvet winding rollers and velvet fiber stripping rollers. The raw velvet winding rollers include the first roller sleeve 1 and the first roller shaft. 2. The first roller shaft 2 is a solid cylindrical structure, the first roller sleeve 1 is a ring structure, the first roller sleeve 1 is tightly sleeved on the first roller shaft 2, and one end of the first roller shaft 2 protrudes from the first Roller sleeve 1, the end of first roller shaft 2 protruding from the first roller sleeve 1 is driven to rotate by the first motor through the first belt. The velvet fiber stripping roller comprises a second roller sleeve 4 and a second roller shaft 5, the second roller shaft 5 is a solid cylindrical structure, the second roller sleeve 4 is a ring structure, and the second roller sleeve 4 is tightly sleeved on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com