Method for recovering tetrabutylammonium hydroxide by electrolysis of tetrabutylammonium sulfate solution

A technology of tetrabutylammonium hydroxide and tetrabutylammonium sulfate, applied in chemical instruments and methods, sulfur compounds, sulfur trioxide/sulfuric acid, etc., can solve the problems of increased recycling costs, waste of resources, pollution, etc., to reduce content, Effect of improving purity and improving recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

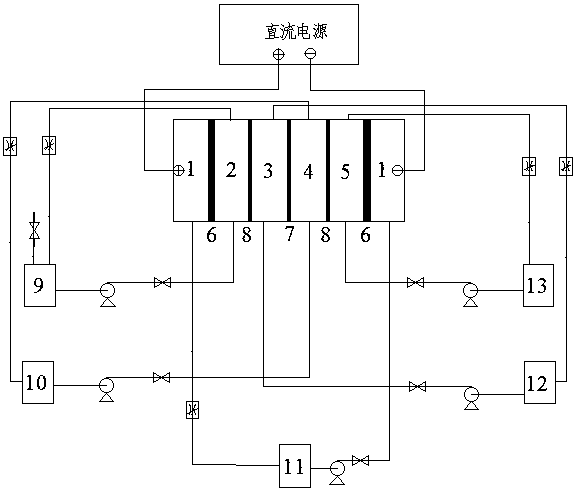

[0018] Will contain 30g / L of (TBA) 2 SO 4 The solution is subjected to four-compartment bipolar membrane electrodialysis with an intermediate liquid chamber. The equipment uses Japanese bipolar membranes, Japanese cation exchange membranes and German anion exchange membranes. The intermediate liquid chamber is 0.05mol / L sulfuric acid solution. The current of the electrolysis process The density is 200A / m 2 , the flow rate of the feed liquid chamber is 0.2L / h, and the electrodialysis is 1.5h. At the end, the conductivity of the solution in the feed liquid chamber is 835μs, and the conductivity of the solution in the lye chamber is 7.3ms, generating 0.15mol of tetrabutylammonium hydroxide, tetrabutylammonium hydroxide The recovery rate>99%, the purity reaches 98.9%, is concentrated to the mass fraction and is that the sulfate ion content is lower than 1500ppm in the tetrabutyl ammonium hydroxide solution of 40%.

Embodiment 2

[0020] Will contain 70g / L of (TBA) 2 SO 4 The solution is subjected to four-compartment bipolar membrane electrodialysis with an intermediate liquid chamber. The equipment uses Japanese bipolar membranes, Japanese cation exchange membranes and German anion exchange membranes. The intermediate liquid chamber is 0.1mol / L sulfuric acid solution. The current of the electrolysis process The density is 200A / m 2 , the feed liquid chamber flow rate is 0.2L / h, electrodialysis 3h, the conductivity of the solution in the feed liquid chamber is 1068μs at the end, and the conductivity of the solution in the lye chamber is 11.2ms, generating 0.38mol of tetrabutylammonium hydroxide, tetrabutylammonium hydroxide The recovery rate>99%, the purity reaches 98.2%, and the content of sulfate ion in the tetrabutylammonium hydroxide solution concentrated to 40% by mass fraction is lower than 2800ppm.

Embodiment 3

[0022] Will contain 200g / L of (TBA) 2 SO 4 The solution is subjected to four-compartment bipolar membrane electrodialysis with an intermediate liquid chamber. The equipment uses Japanese bipolar membranes, Japanese cation exchange membranes and German anion exchange membranes. The intermediate liquid chamber is 0.1mol / L sulfuric acid solution. The current of the electrolysis process The density is 200A / m 2 , the flow rate of the feed liquid chamber is 0.2L / h, electrodialysis is 8.5h, the conductivity of the solution in the feed liquid chamber is 1.3ms at the end, and the conductivity of the solution in the lye chamber is 32.5ms, generating 0.93mol of tetrabutylammonium hydroxide, tetrabutylammonium hydroxide The recovery rate of ammonium is more than 99%, and the purity reaches 98.6%. The sulfate ion content in the tetrabutylammonium hydroxide solution concentrated to a mass fraction of 40% is lower than 4500ppm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com