Treating method and treating device for zero discharging of desulfurization wastewater

A treatment method and technology for desulfurization wastewater, applied in the direction of gaseous effluent wastewater treatment, multi-stage water treatment, water/sewage treatment, etc., can solve the problems of operation stability and poor treatment effect, and achieve the elimination of scaling and improve stability Sexuality, the effect of reducing hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

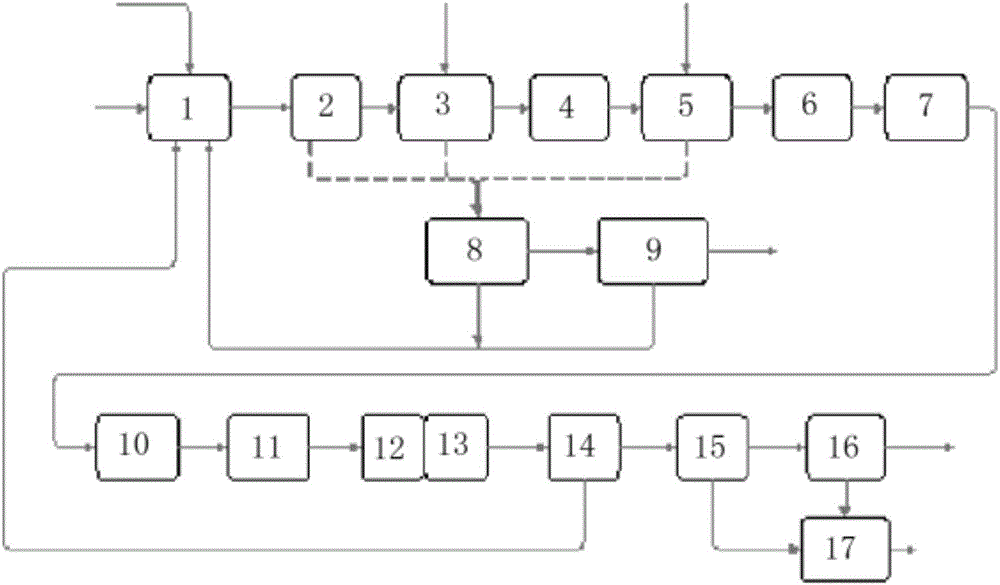

Image

Examples

Embodiment 1

[0050] This embodiment provides a zero-discharge treatment method for desulfurization wastewater. The processing method includes the following steps:

[0051] (1) The desulfurization wastewater of a coal-fired power plant enters the aeration adjustment device for aeration treatment, and the aeration-treated wastewater enters the pre-sedimentation device for static precipitation, and the first effluent is collected. Among them, the COD in the desulfurization wastewater is 1000mg / L, TDS66800mg / L, Na + 4600mg / L, Cl - 13000mg / L, Mg 2+ 44000mg / L, Ca 2+ 2400mg / L, SO 4 2- 36000mg / L, SiO 2 250mg / L, TSS13000mg / L, pH 6.5, turbidity 752.8NTU, first effluent COD 186mg / L, TDS41000mg / L, Na+4000mg / L, Cl - 8200mg / L, Mg 2+ 23800mg / L, Ca 2+ 1400mg / L, SO 4 2- 21200mg / L, SiO 2 <135mg / L, TSS 708mg / L, turbidity 23.71NTU, turbidity removal rate reaches 96.9%;

[0052] (2) The first effluent enters the coagulation treatment device for coagulation treatment, and the coagulation treatment...

Embodiment 2

[0058] This embodiment provides a zero-discharge treatment method for desulfurization wastewater. The processing method includes the following steps:

[0059] (1) The desulfurization wastewater of a coal-fired power plant enters the aeration adjustment device for aeration treatment, and the aeration-treated wastewater enters the pre-sedimentation device for static precipitation, and the first effluent is collected. Among them, the COD in the desulfurization wastewater is 1000mg / L, TDS55800mg / L, Na + 4300mg / L, Cl - 12000mg / L, Mg 2+ 40000mg / L, Ca 2+ 2500mg / L, SO 4 2- 22000mg / L, SiO 2 250mg / L, TSS17000mg / L, pH 6.0, turbidity 752.8NTU, first effluent COD 140mg / L, TDS34260mg / L, Na+3741mg / L, Cl - 7560mg / L, Mg 2+ 21600mg / L, Ca 2+ 1450mg / L, SO 4 2- 12980mg / L, SiO 2 <130mg / L, TSS 900mg / L, turbidity 23.6NTU;

[0060] (2) The first effluent enters the coagulation treatment device for coagulation treatment, and the coagulation treatment device is added with a dosage of 1000m...

Embodiment 3

[0066] This embodiment provides a zero-discharge treatment method for desulfurization wastewater. The processing method includes the following steps:

[0067] (1) The desulfurization wastewater of a coal-fired power plant enters the aeration adjustment device for aeration treatment, and the aeration-treated wastewater enters the pre-sedimentation device for static precipitation, and the first effluent is collected. Among them, the COD in the desulfurization wastewater is 1000mg / L, TDS66800mg / L, Na + 4600mg / L, Cl - 13000mg / L, Mg 2+ 44000mg / L, Ca 2+ 2400mg / L, SO 4 2- 36000mg / L, SiO 2 250mg / L, TSS13000mg / L, pH 6.5, turbidity 752.8NTU, first effluent COD 180mg / L, TDS41000mg / L, Na+4000mg / L, Cl - 8200mg / L, Mg 2+ 23800mg / L, Ca 2+ 1400mg / L, SO 4 2- 21200mg / L, SiO 2 <135mg / L, TSS 708mg / L, turbidity 23.71NTU;

[0068] (2) The first effluent enters the coagulation treatment device for coagulation treatment. In the coagulation treatment device, iron-based flocculant with a d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com