Regeneration system and method of solder stripping waste water

A waste liquid and tin stripping technology, which is applied in the direction of improving process efficiency, can solve the problems of high copper-containing impurities and low added value of tin, and achieve the effects of reducing impurity content, simplifying recovery and treatment, and improving recovery purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

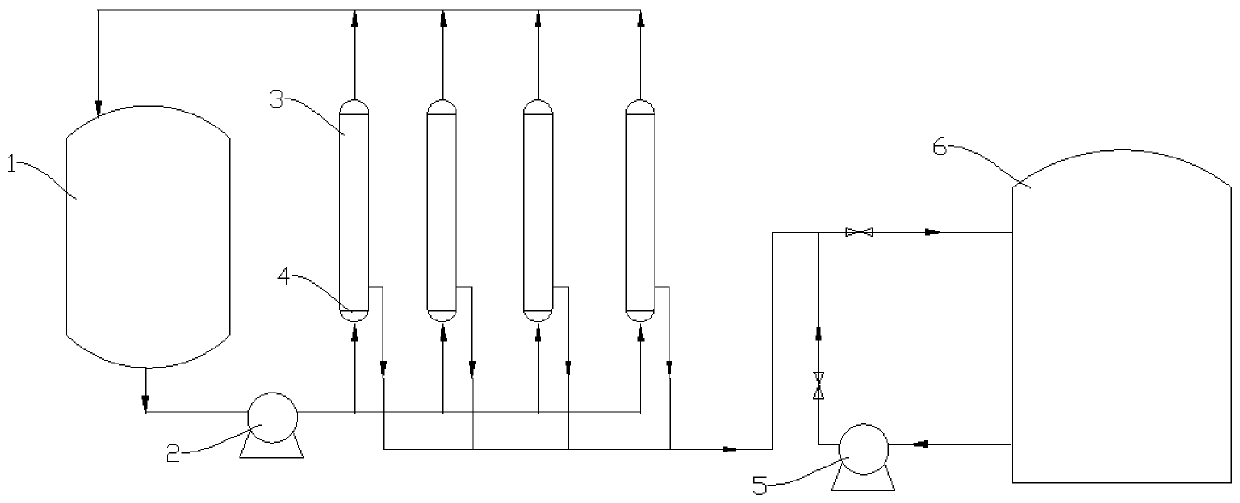

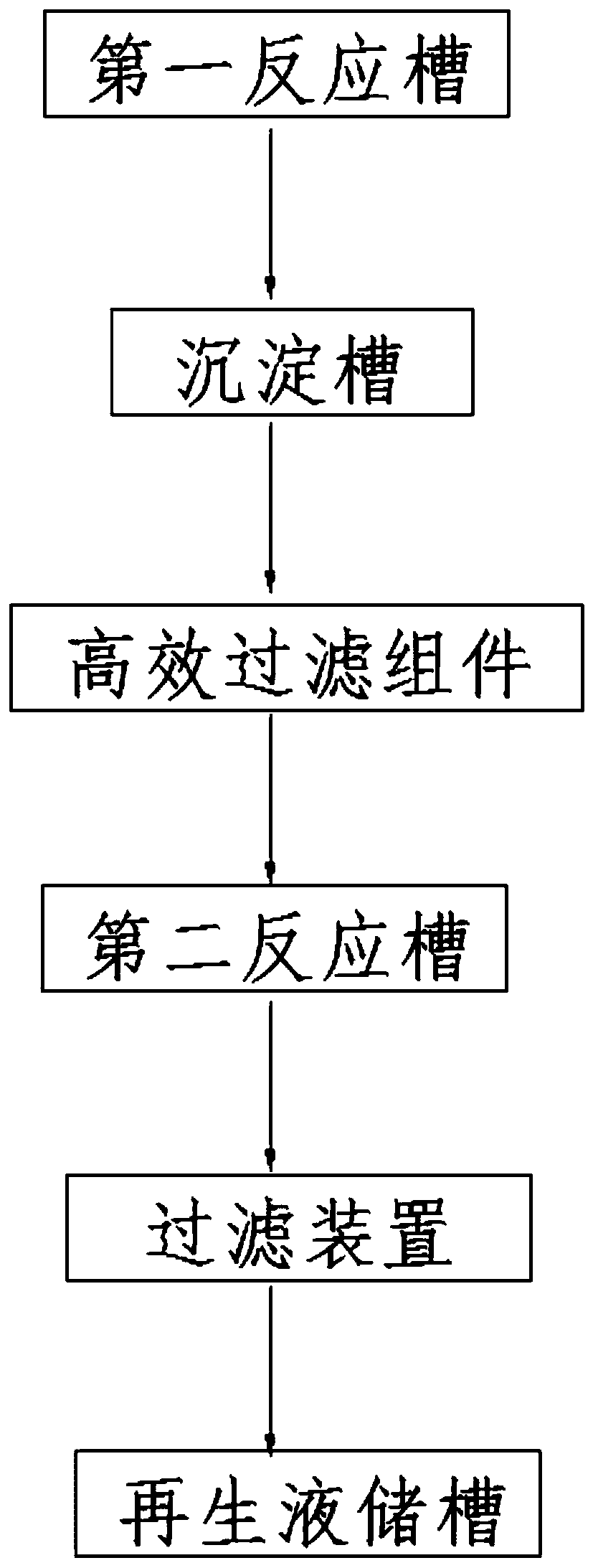

[0043] This embodiment provides a high-efficiency filter assembly. The high-efficiency filter assembly includes a plurality of filter devices 3, and the plurality of filter devices 3 are connected in series or in parallel through pipelines, which can be increased or decreased according to the amount of waste liquid. The filtration capacity is greatly improved; the filter layer 4 in the filter device 3 has a filter aperture of 1-200nm, which can filter ultrafine particles such as β-stannic acid; the turbid liquid filtered by the filter device 3 can be circulated and filtered again, so that The liquid is clearer and not cloudy. When the present invention filters the pretreated β stannic acid in the waste liquid, the waste liquid in the waste liquid tank 1 passes through the feed high-pressure pump 2, and after filtering through the filter device 3, turbid liquid and clear liquid are respectively obtained; turbid The liquid returns to the waste liquid tank 1 through the original ...

Embodiment 2

[0045] The content / concentration of each component of the tin stripping waste liquid used in this embodiment is as follows: the content of tin is 100g / L, the content of copper ions is 6g / L, the content of iron ions is 16g / L, and the residual nitric acid is 25%.

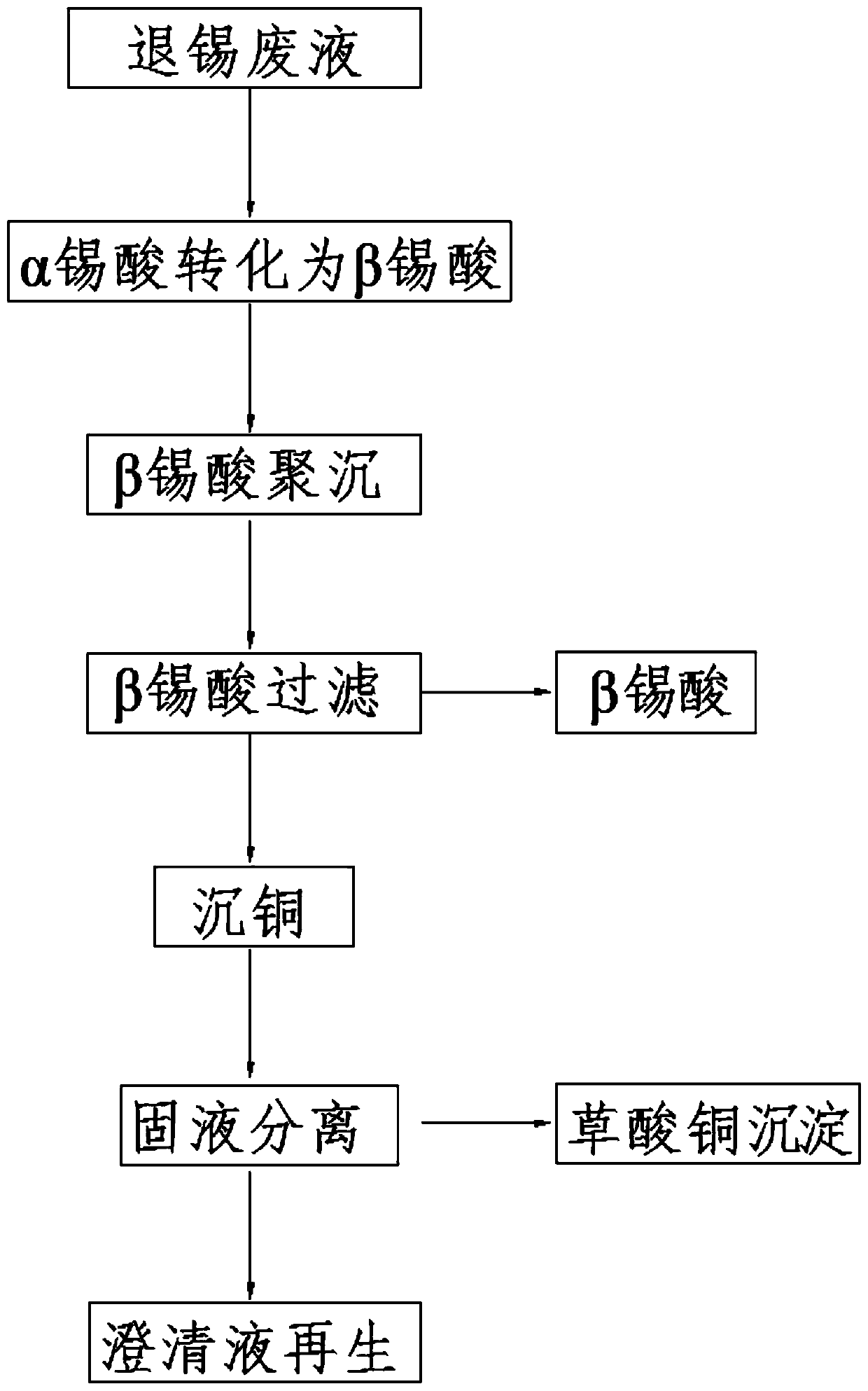

[0046] A method for regenerating tin stripping waste liquid, comprising the following steps: adding nitric acid to the tin stripping waste liquid, simultaneously aerating for 1 hour and standing for heat preservation at 30°C, so that the alpha stannic acid in the waste liquid is completely converted into beta stannic acid; Then add hydrochloric acid and sulfonate to the waste liquid, heat it to 30-40°C, keep it warm, and let it stand for 8 hours; make the β-stannic acid in the waste liquid coagulate; use high-efficiency filter components to filter the precipitated β-stannic acid , the recovery rate of tin is 95.9%, and the impurity content is 1.4%; Then add oxalic acid, make the precipitation of a small amount of coppe...

Embodiment 3

[0050] The content / concentration of each component of the tin stripping waste liquid used in this embodiment is as follows: the tin content reaches more than 110g / L, the copper ion content is 8g / L, the iron ion content is 17g / L, and the residual nitric acid content is 24%.

[0051] A regeneration method for tin stripping waste liquid, comprising the following steps: introducing ozone into the tin stripping waste liquid, simultaneously aerating for 1.5 hours and standing for heat preservation at 35°C, so that the α-stannic acid in the waste liquid is completely converted into β-tin acid; then add sulfuric acid and fatty acid salt to the waste liquid, heat to 35°C at the same time, keep it warm, and let it stand for 9 hours to make the β-stannic acid in the waste liquid coagulate; use high-efficiency filter components to filter the β-stannic acid precipitate , the recovery rate of tin is 96.3%, and the impurity content is 1.2%; Then add oxalic acid, make the precipitation of a sm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com