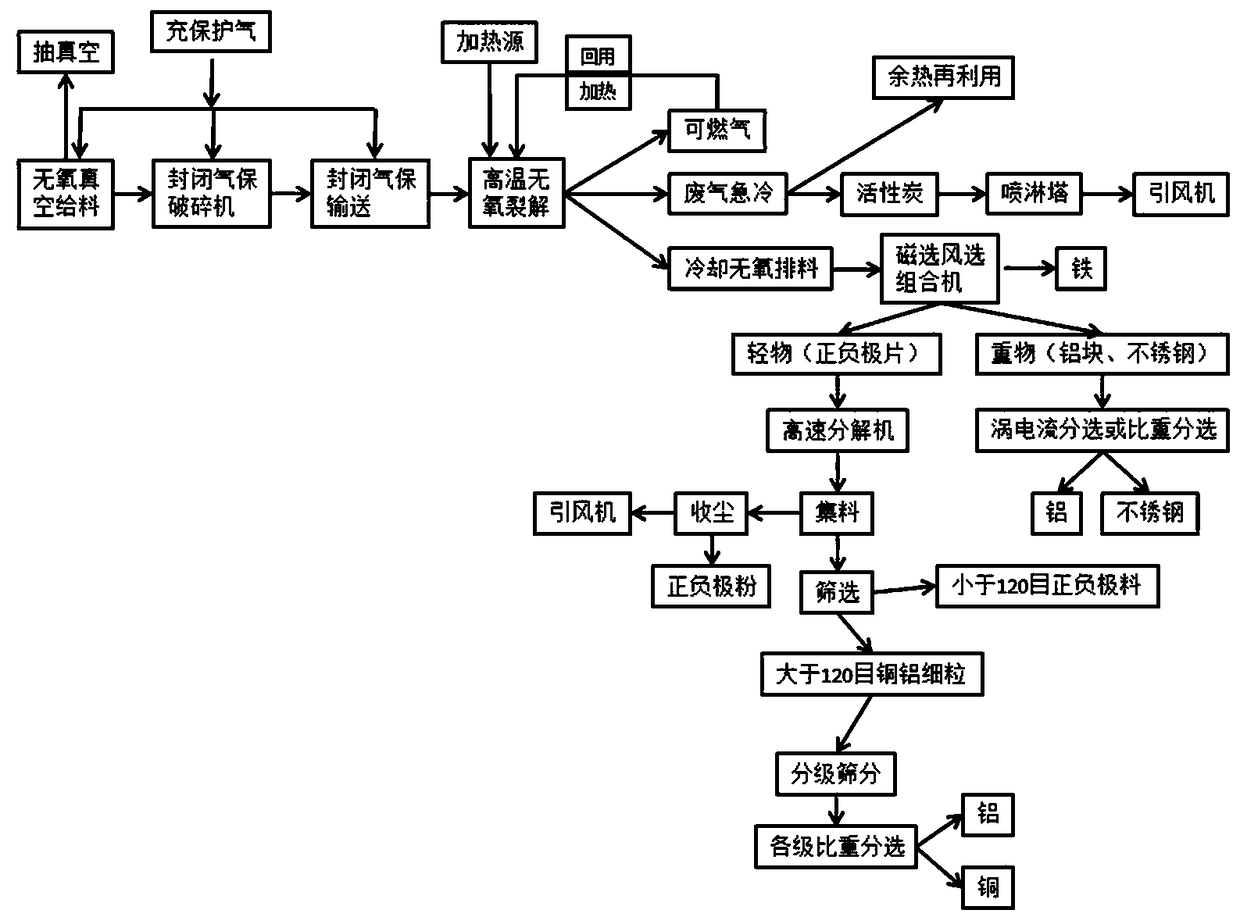

Crushing and recycling process of lithium battery after anaerobic cracking

A lithium battery and post-cracking technology, which is applied in the field of crushing and recycling technology after anaerobic cracking of lithium batteries, can solve the problems of inability to remove plastic particles and plastic films, low purity of recycled materials, waste of water resources, etc., so as to save energy, The effect of preventing thermal discharge and reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The lithium battery is dismantled and discharged, and the disassembled and discharged lithium battery is sent to the crusher for crushing; the crushed material is connected to the cyclone collector with negative pressure through the conveying pipeline, and the dust collection system of the cyclone collector is collected Positive and negative electrode powder, the fan of the dust collection system will condense and recycle the gas drawn out, and the condensed and recovered gas will be discharged after waste gas treatment; the material will be vacuumed after passing through the cyclone collector and transported to the high-temperature anaerobic cracking furnace through the conveying device. The temperature of the high-temperature anaerobic cracking furnace is above 300°C. The high-temperature anaerobic cracking furnace is vacuumized and kept closed before adding the crushed materials. The conveying device is kept in a vacuum state during the conveying process. The doped pl...

Embodiment 2

[0045] Through the anaerobic feeder, the charged lithium battery is sent to the closed air-protected crusher with protective gas continuously for crushing. The protective gas is continuously fed into the air, and the connection between the entrance of the closed air-protected crusher and the anaerobic feeder is sealed. After the crushed material is vacuumed, it is transported to the High-temperature anaerobic cracking furnace, the temperature of the high-temperature anaerobic cracking furnace is above 300°C, the high-temperature anaerobic cracking furnace is vacuumized and kept closed before adding the crushed materials, and the conveying device is maintained during the conveying process In a vacuum state, the plastic doped in the mixed material is cracked to produce combustible gas, which is discharged and collected. After the cracked mixed material, only the positive and negative electrodes and metal are left; the cracked mixture is discharged from the high-temperature anaero...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com