Waste circuit board fixed bed pyrolyzing system heated through high-temperature gas seepage

A technology of waste circuit boards and high-temperature gas, which is applied to the removal of solid waste, thermometers, and heat measurement. It can solve the problems of corrosion pyrolysis heating temperature, affecting heat transfer, and large thermal resistance, and achieves high recovery rate and recovery purity. , Improve pyrolysis efficiency and reduce pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

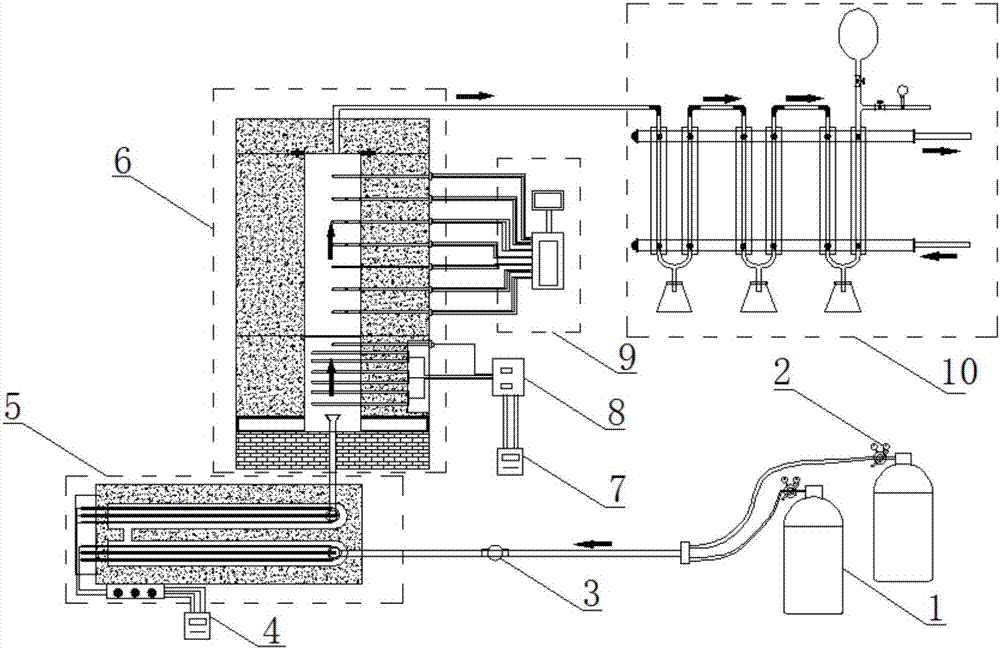

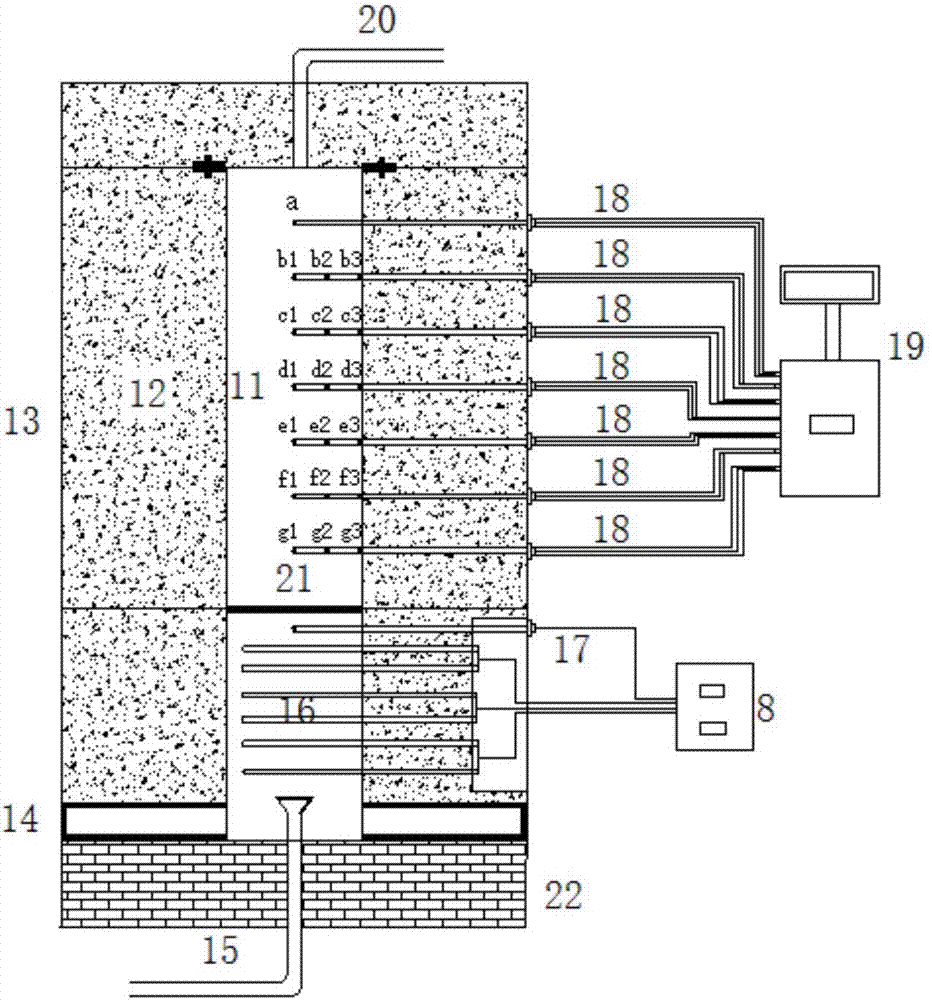

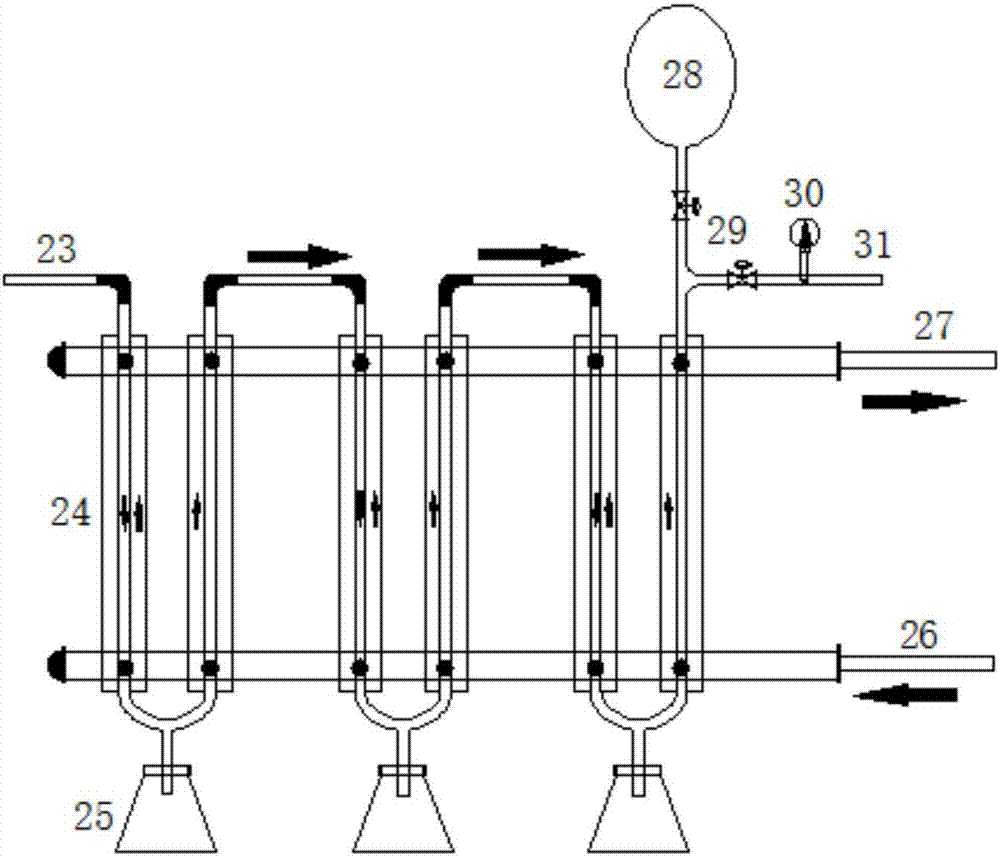

[0013] Such as figure 1 A fixed-bed pyrolysis system for waste circuit boards heated by high-temperature gas percolation shown in the present invention includes a pyrolysis furnace 6, and the pyrolysis furnace 6 includes a furnace body, and the furnace body is supported by heat insulating bricks 22 Above, a furnace cover is fixed on the top of the furnace body, and the furnace body includes a pyrolysis furnace hearth 11 surrounded by an inner tank, and the outer wall of the inner tank is covered with a thermal insulation structure 12 and a pyrolysis furnace in turn. The outer wall 13 of the furnace is provided with a soot cleaning port 14 at the bottom of the furnace body to clean up the dust falling from the orifice plate of the pyrolysis furnace. A porous orifice plate 21 is installed along the horizontal direction at the bottom of the pyr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com