Method for separating oligomers from polyphenylene sulfide resin synthesis slurry

The technology of a polyphenylene sulfide resin and a process method is applied in the field of polyphenylene sulfide resin production technology, and can solve the problems of complete separation of oligomers, difficulty in recovery, catalyst purification, etc., so as to improve economic benefits and product quality, promote The effect of growth and shortening of coagulation and settling time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

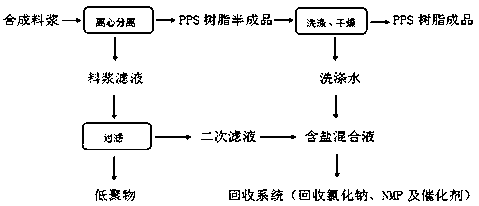

[0042] as attached figure 1 The process method for synthesizing polyphenylene sulfide resin in the prior art includes first synthesizing polyphenylene sulfide resin slurry through raw materials, solvents, catalysts, etc., and then through centrifugation to obtain a PPS resin semi-finished product on the one hand, and the PPS resin After the semi-finished product is washed and dried, the finished product is obtained, and the remaining slurry filtrate contains solvent NMP, oligomers, water, sodium chloride and a small amount of PPS resin particles in the centrifuged separation, which is directly filtered to separate the oligomers and the secondary filtrate, and then Combine the secondary filtrate and PPS resin semi-finished product washing liquid to obtain a salty mixed liquid, and further recover sodium chloride, NMP and catalyst;

[0043] The specific operation is: Synthesize polyphenylene sulfide resin slurry by the sodium sulfide method, then filter the slurry, take 100mL of...

Embodiment 2

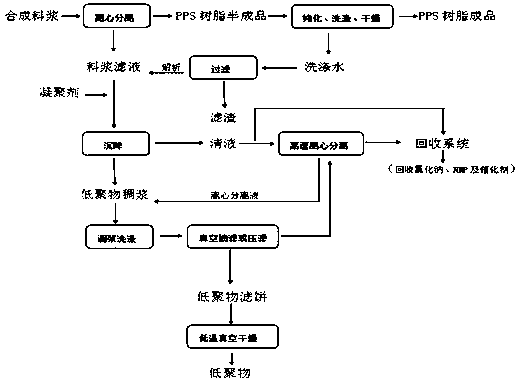

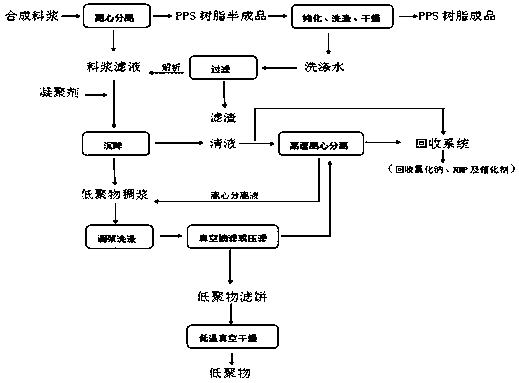

[0045] as attached figure 2 A synthetic process of polyphenylene sulfide resin shown, it comprises the following processes:

[0046] (1) Synthesize polyphenylene sulfide resin by sodium sulfide method;

[0047] (2) Separating the polyphenylene sulfide resin from the synthetic slurry and washing it with water;

[0048](3) Filter the washing water after washing in step (2), collect solid polyphenylene sulfide resin particles, and add the filtered washing water to the remaining synthetic slurry after separation, and the synthetic slurry and the washing The volume ratio of water is 1:1~1:20 to form a mixed slurry;

[0049] (4) Adding the first reagent to the mixed slurry until the pH of the mixed slurry is 2.0-6.0, and then standing for 2-8 hours;

[0050] (5) When the supernatant is settled until it is transparent, send the supernatant to a centrifuge for centrifugation at a speed of 8000~14000rpm, and then send the separated secondary supernatant to the subsequent recovery s...

Embodiment 3

[0052] Use as attached figure 2 A synthetic process of polyphenylene sulfide resin shown,

[0053] (1) Synthesize polyphenylene sulfide resin by sodium sulfide method;

[0054] (2) Separating the polyphenylene sulfide resin from the synthetic slurry, washing it with water, filtering the washing water, and collecting the solid polyphenylene sulfide resin particles and the filtered washing water respectively;

[0055] (3) Take 100mL of the filtrate of the synthetic slurry, add 1000mL of the filtered washing water obtained in step (2) to the filtrate, and measure the pH value of the obtained mixed slurry after stirring to 7.0~8.5; then use 1+1 sulfuric acid Add dropwise into the mixed slurry as the first reagent, stir to adjust the pH value to 5.0~5.5, and then let it settle for 4 hours;

[0056] (4) Overflow pipette 800mL of the primary clear liquid after standing still, separate it with a 14000rpm high-speed centrifuge, test the oligomer content of the separated secondary cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com