Binary composite cigarette filter stick

A filter rod, binary composite technology, applied in the direction of e-liquid filter element, tobacco, application, etc., can solve the problems of high cost, complicated process, no application, etc., achieve high adsorption force, simplified manufacturing process, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

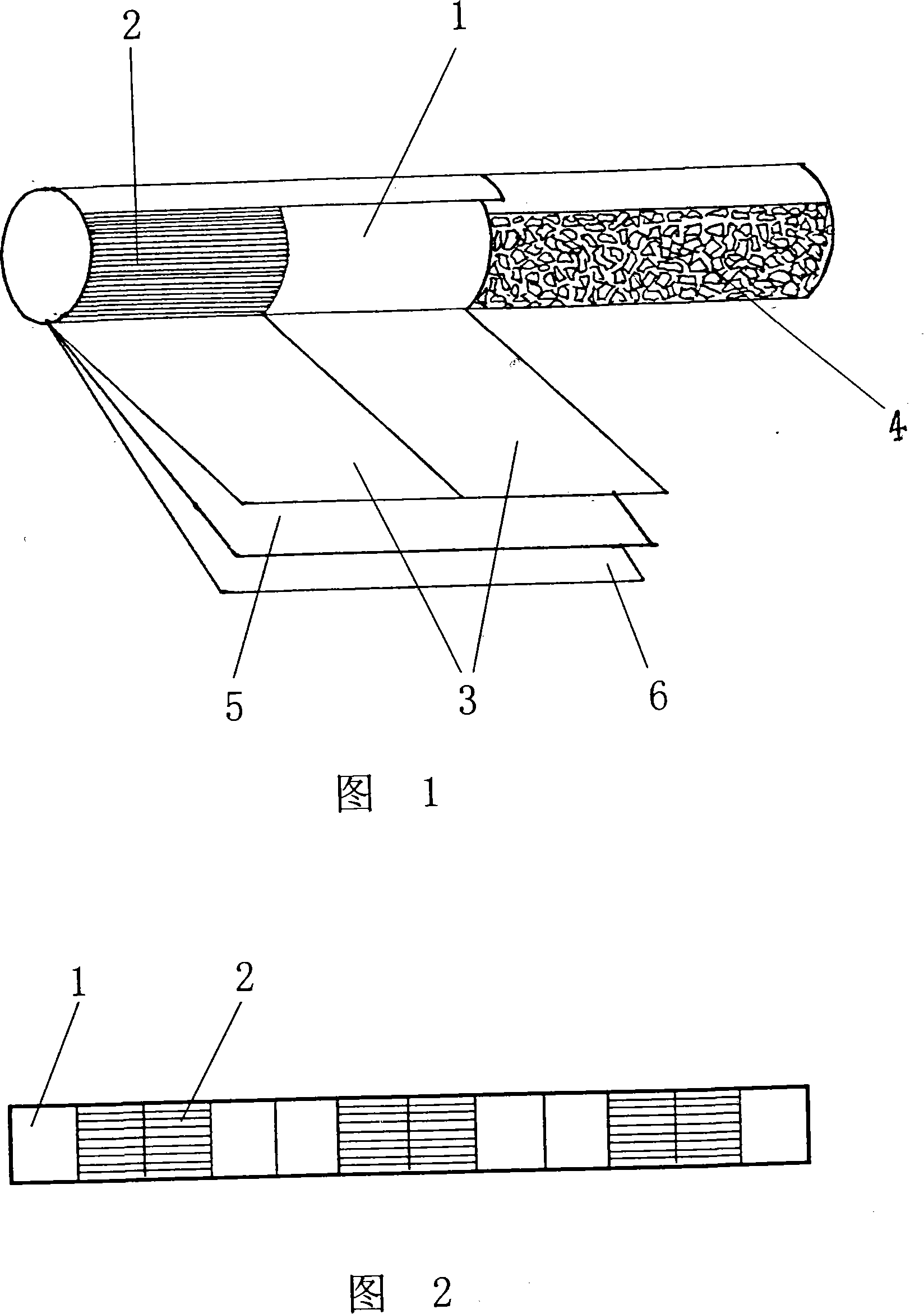

Embodiment 1

[0017] First take the unit area mass as 40g / m 2 , Thickness 1mm, width 14cm strip puffed airlaid paper, airlaid paper is made of pure wood pulp. Place the long dry-laid paper on the feeding device of the filter rod forming machine, and wrap the forming paper to make a filter rod, which is used as a unitary component of the binary composite rod near the end of the tobacco; then select ordinary acetate filament bundles to open first, and then Spray cellosolve on the surface of the tow after opening, put it on the feeding device of the filter rod forming machine, wrap the forming paper into a rod, and use it as a unit of the suction end of the binary composite filter rod. Then make the binary compound filter stick on the composite machine. All indicators of the binary compound filter stick meet the national standards, and the filtration rate is higher than that of the ordinary cellulose acetate filter stick. The taste is pure, no peculiar smell, no spicy Taste, aftertaste is cle...

Embodiment 2

[0019] First take the unit area mass as 60g / m 2 , The thickness is 1.5mm, and the width is 10cm strip-shaped puffed dry-laid paper, which contains 25% composite fiber and 75% wood pulp in the puffed dry-laid paper. Cut the 10cm long dry-laid paper into three strips of equal width and stack them on the feeding device of the filter rod forming machine, wrap the forming paper to make a filter rod, which is used as a unit of the binary composite rod near the end of the shredded tobacco; Choose ordinary acetate fiber tow to open first, spray cellosolve on the surface of the tow after opening, put it on the feeding device of the filter rod forming machine, wrap the forming paper into a rod, and use it as the suction of the binary composite filter rod. end of the dollar. Then compound the above two components on a composite machine to form a binary compound filter stick. All indicators of this binary compound filter stick meet the national standards, and the filtration rate is highe...

Embodiment 3

[0021] First take the unit area mass as 45g / m 2 , Thickness is 1.3mm, width is 13cm elongated puffed dry-laid paper, this puffed dry-laid paper has added the active carbon particle of paper total amount 3% when air-laid. Place the dry-laid paper on the feeding device of the filter rod forming machine, and wrap the forming paper to make a filter rod, which is used as a unit of the binary composite rod near the end of the tobacco; then use ordinary acetate filament bundles to open first, and then loosen them The surface of the final tow is sprayed with cellosolve, placed on the feeding device of the filter rod forming machine, wrapped with forming paper to form a rod, and used as a unit of the binary composite filter rod near the suction end. Then compound the above two components on a composite machine to form a binary compound filter stick. All indicators of this binary compound filter stick meet the national standards, and the filtration rate is higher than that of a common c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com