Method for preparing nanofiber membrane modified paper base material based on electrostatic spinning and application of nanofiber membrane modified paper base material

A technology of nanofiber membrane and paper base material, applied in the field of tobacco filter material, can solve the problems of cost reduction, large amount of acetate fiber, disadvantage, etc., and achieve the effects of reducing release amount, simple preparation method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

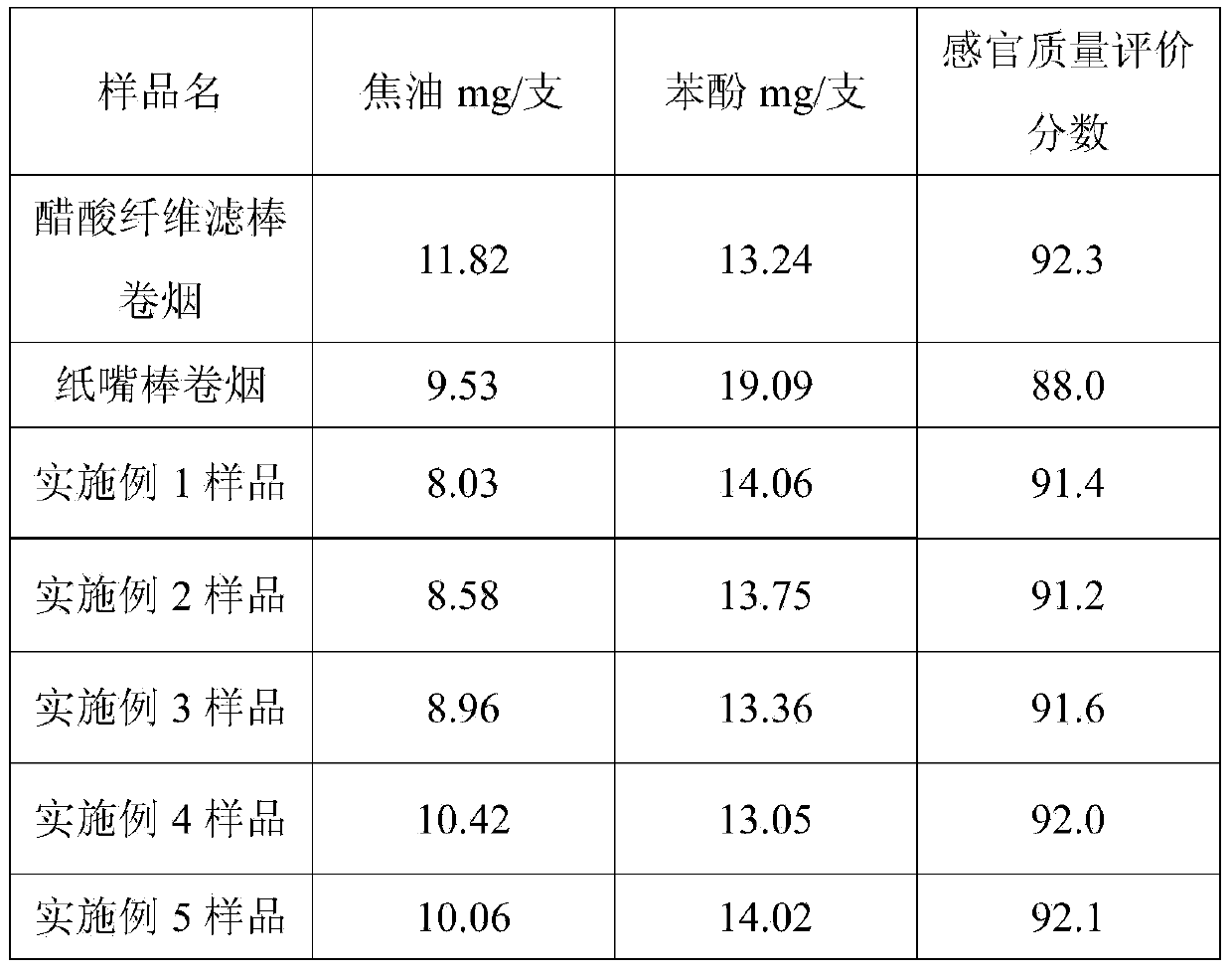

Examples

Embodiment 1

[0024] The cellulose acetate solution is spun separately, and the spinning is carried out in the electrospinning chamber. Dissolve cellulose acetate in acetone to prepare an 8% (W / W) solution, place it in a storage tank, and supply the material liquid to 400 electrospinning nozzles at a speed of 4mL / h per pump through a computer-controlled micropump , the electrospinning voltage is 20KV, the distance between the nozzle and the paper substrate is 20cm, the temperature of the electrospinning environment is 50°C, each group of electrospinning nozzles is 20 nozzles, each group of nozzles forms a circuit, and each group of nozzles in the circuit Rotate continuously at a constant speed in order to make the electrospinning uniform on the receiving substrate. One end of the electrospinning chamber is continuously fed with air, and the other end discharges the air mixed with solvent from the electrospinning chamber for solvent recovery. Paper made of wood pulp fibers is used as a subs...

Embodiment 2

[0026] The polylactic acid fiber (PLA) solution was spun separately. Electrospinning was performed in the electrospinning chamber in Example 1. The spinning equipment is the same as in Example 1. Polylactic acid fiber (PLA) was dissolved in dichloromethane to prepare a 12% (W / W) solution. At room temperature, using a voltage of 15KV and a curing distance of 10cm, the advancing speed of the spinning solution was 2mL / h. It is spun, and the paper made of hemp pulp fiber is used as the substrate to receive polylactic acid nanofibers, and a film layer of white nanofibers with a diameter of about 800 μm is prepared on the base paper to prepare a paper containing electrospun nanofiber membranes. Material, the spraying amount of the nanofiber film on the paper substrate is about 0.3g / m 2 .. The net embossed paper material containing electrospun nanofibers was cut into a narrow width of 26cm, and it was prepared into a filter rod with a tip forming machine and rolled into a cigarett...

Embodiment 3

[0028] The chitosan and polycaprolactam blend solution was spun. Electrospinning was performed in the electrospinning chamber in Example 1. The spinning equipment is the same as in Example 1. Dissolve chitosan in acetic acid to prepare a 7% (W / W) solution, dissolve polycaprolactam in formic acid to prepare a 8% (W / W) solution, mix the two solutions at a mass ratio of 30:70, and set the temperature at room temperature Under the condition of using a voltage of 30KV and a solidification distance of 15cm, the propulsion speed of the spinning solution is 1.0mL / h, and it is spun, and the paper made of hemp pulp fiber is used as a substrate to receive chitosan and polycaprolactam nanofibers, Prepare a film layer of white nanofibers with a diameter of about 600nm on the base paper, and prepare a paper material containing an electrospun nanofiber film. The spraying amount of the nanofiber film on the paper substrate is about 0.2g / m 2 .. The net embossed paper material containing ele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com