Paper filtering and folding machine of full-automatic filter

A filter and fully automatic technology, applied in the direction of machining/deformation, can solve the problems of wasting labor, rising manufacturing costs, and low production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

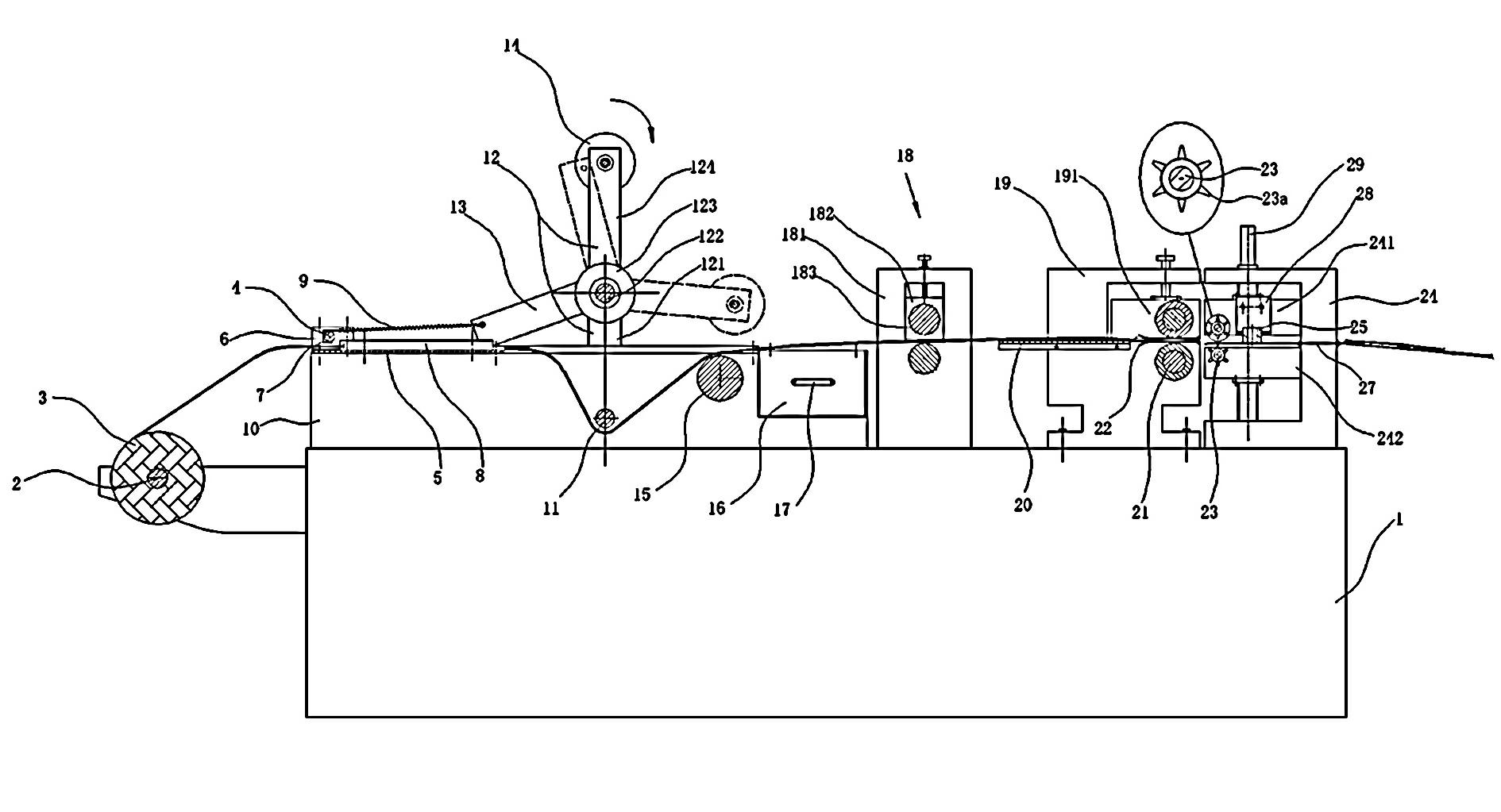

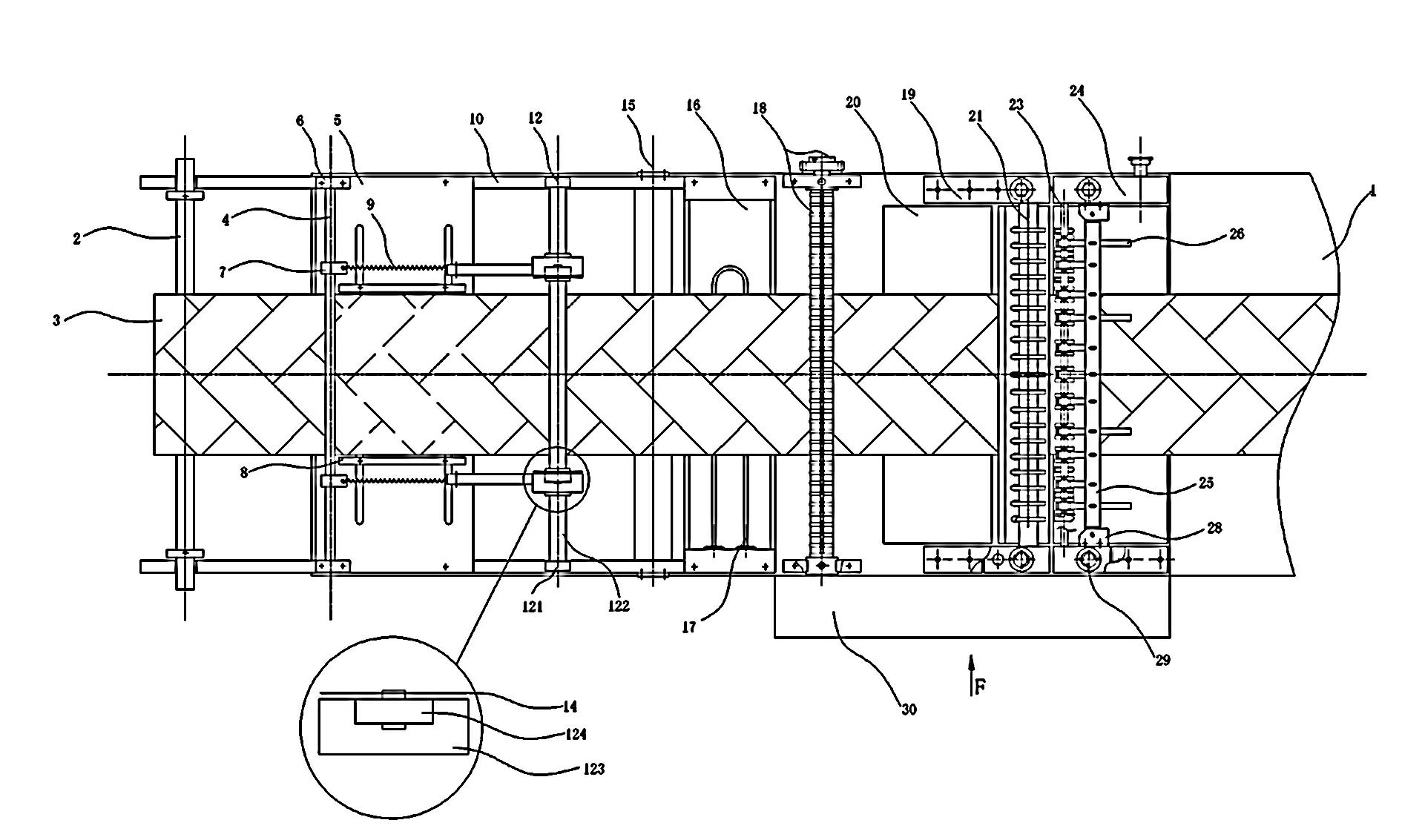

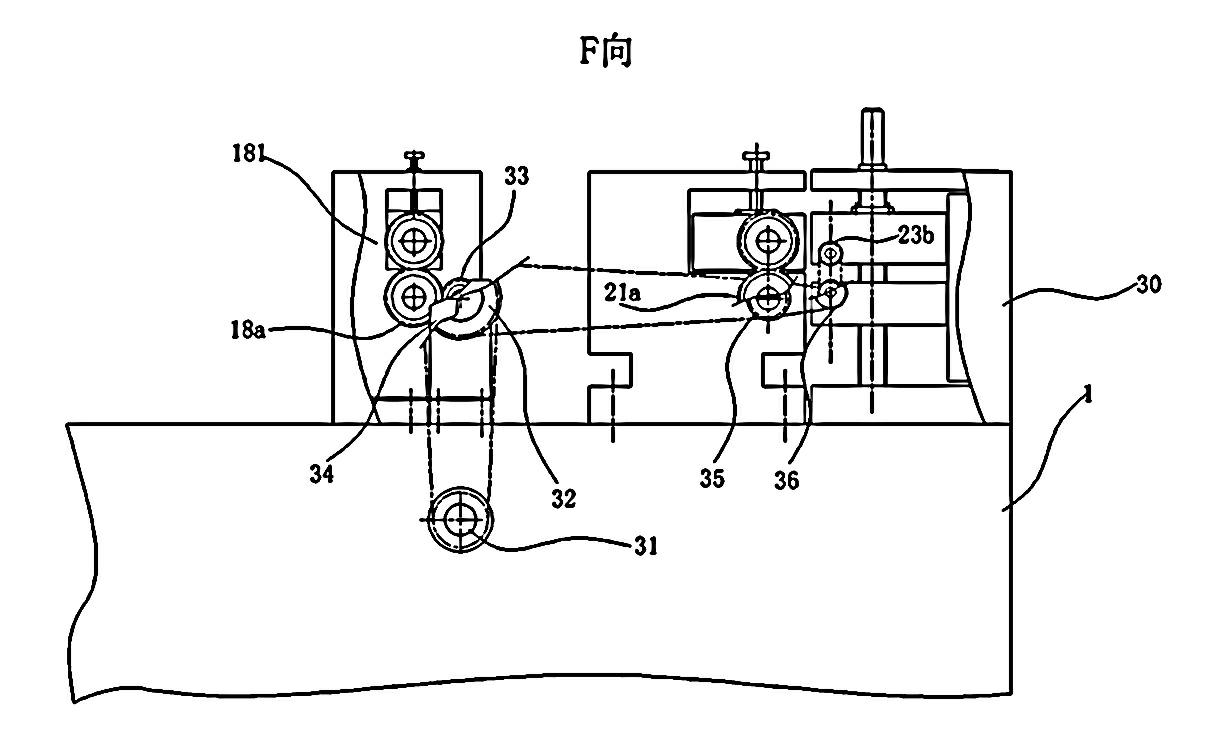

[0014] Such as figure 1 As shown, what the present invention provides is a kind of automatic filter paper folding machine, comprising: a frame 1, the tail of the frame is provided with two triangular support frames, and each support frame is all provided with a groove; Set a clamping rod 2, its two ends are placed in the groove, each end is connected with a positioning wheel, the two ends of the clamping rod are fixed, and the axial movement of the clamping rod is prevented; the unrolled filter paper 3 is clamped In the middle part of the clamping rod 2. The horizontal workbench of the frame 1 is provided with a guide plate, a slitting and tensioning mechanism, a hot steaming water tank, a crimping mechanism, a friction folding mechanism and a ratchet folding mechanism in sequence from left to right. The filter paper 3 is transported forward through the guide plate, first processed into a certain size by slitting and tightening, and then steamed and humidified in the hot stea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com